-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 14, 2025 18:21 Back to list

Perforated Metal Mesh

Custom perforated metal sheets have become indispensable across various industries, emerging as an essential component due to their versatility and enhanced design opportunities. Their unique characteristics make them highly valued for both aesthetic and functional applications, influencing industries from architecture to manufacturing. Drawing from extensive experience, this article offers insights into why these metal sheets are not only sought-after but also trusted for their quality and customization capabilities.

Sustainability is a considerable advantage offered by these metal sheets. The metal materials involved, often stainless steel or aluminum, are recyclable. This not only ensures that the products contribute to reducing environmental waste but also makes them attractive for projects focusing on sustainability. An expert in the field would emphasize the importance of selecting high-quality metals that offer both strength and ecological benefits, aligning with modern sustainable practices. A reliable indicator of trustworthiness in custom perforated metal product suppliers is their adherence to industry standards and certifications. Companies with ISO certifications or those that comply with ASTM specifications demonstrate their commitment to producing high-quality, consistent products. This authority in production is critical for industries that cannot compromise on material quality, such as aerospace or automotive sectors. Furthermore, supplier experience and expertise impact the product's usability and application flexibility. Industries benefit from suppliers who possess a comprehensive understanding of material science and application environments, offering technical support and guidance through the design process. This partnership ensures that the chosen perforation patterns align with the project’s aesthetic and functional goals, fostering innovation and efficiency. In summary, custom perforated metal sheets offer an array of benefits across different sectors, driven by their customization capabilities, durability, and aesthetic potential. Sharing insights from experienced professionals within the industry helps underline the sheets' multifaceted applications, reinforcing their status as an invaluable resource. With continuous advancements in manufacturing technology, these metal sheets promise further innovations, meeting evolving industry demands while maintaining high standards of quality and performance.

Sustainability is a considerable advantage offered by these metal sheets. The metal materials involved, often stainless steel or aluminum, are recyclable. This not only ensures that the products contribute to reducing environmental waste but also makes them attractive for projects focusing on sustainability. An expert in the field would emphasize the importance of selecting high-quality metals that offer both strength and ecological benefits, aligning with modern sustainable practices. A reliable indicator of trustworthiness in custom perforated metal product suppliers is their adherence to industry standards and certifications. Companies with ISO certifications or those that comply with ASTM specifications demonstrate their commitment to producing high-quality, consistent products. This authority in production is critical for industries that cannot compromise on material quality, such as aerospace or automotive sectors. Furthermore, supplier experience and expertise impact the product's usability and application flexibility. Industries benefit from suppliers who possess a comprehensive understanding of material science and application environments, offering technical support and guidance through the design process. This partnership ensures that the chosen perforation patterns align with the project’s aesthetic and functional goals, fostering innovation and efficiency. In summary, custom perforated metal sheets offer an array of benefits across different sectors, driven by their customization capabilities, durability, and aesthetic potential. Sharing insights from experienced professionals within the industry helps underline the sheets' multifaceted applications, reinforcing their status as an invaluable resource. With continuous advancements in manufacturing technology, these metal sheets promise further innovations, meeting evolving industry demands while maintaining high standards of quality and performance.

Next:

Latest news

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

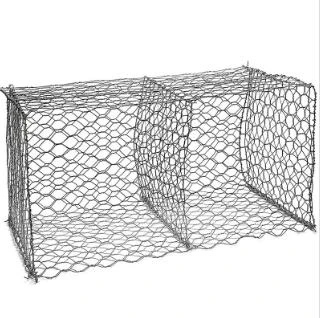

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025