-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 11, 2024 05:11 Back to list

Top Manufacturers of Galvanized Square Wire Netting for Various Applications

Understanding Galvanized Square Wire Netting Manufacturers and Applications

Galvanized square wire netting is a versatile product widely used across various industries due to its durability, strength, and resistance to rust and corrosion. This wire netting is made by drawing steel wire and then applying a layer of zinc through galvanization, providing a protective barrier that extends the wire’s lifespan. In this article, we will explore the importance of galvanized square wire netting, the processes involved in its manufacturing, and the leading manufacturers in this sector.

The Importance of Galvanized Square Wire Netting

Galvanized square wire netting serves various purposes, from agricultural applications to construction and security. Its robust design makes it suitable for fencing, animal enclosures, and protective barriers. In agriculture, it is frequently utilized to create safe confines for livestock, ensuring their safety while also protecting crops from wildlife. Additionally, it is employed in horticulture for plant support and in the construction industry for various reinforcement applications.

The benefits of using galvanized wire netting are manifold. The galvanization process prevents rust and corrosion, which can be particularly damaging in outdoor settings. This makes galvanized square wire netting a long-lasting choice, minimizing the need for frequent replacements. Moreover, the square shape of the netting provides ample structural integrity while allowing for optimal visibility and air circulation, making it ideal for various uses.

The Manufacturing Process

The manufacturing of galvanized square wire netting involves several critical steps to ensure the highest quality product. The process begins with selecting high-quality steel wire, which is then drawn to the desired gauge. After this, the wire undergoes a galvanization process where it is coated with a uniform layer of zinc. This can be done either through hot-dip galvanization, which involves immersing the wire in molten zinc, or electro-galvanization, which uses an electrochemical process to apply the zinc coating.

Once the galvanization is complete, the wire is processed into netting. This involves weaving the wire into a square mesh pattern, which provides stability and uniformity. The finished product is then inspected for any defects, ensuring it meets industry standards before being packaged for distribution.

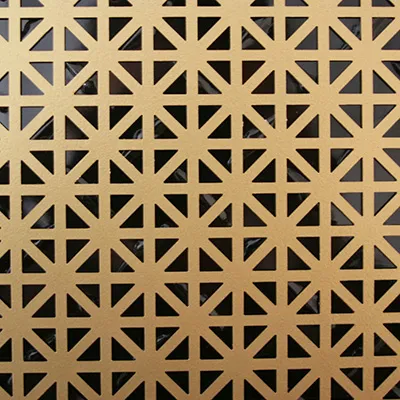

galvanized square wire netting manufacturers

Leading manufacturers in the galvanized square wire netting market often employ highly automated production lines that enhance efficiency and consistency. By keeping up with technological advancements, these manufacturers can produce high-quality wire netting that meets the evolving demands of their customers.

Leading Manufacturers

Several manufacturers are recognized as leaders in the galvanized square wire netting industry, known for their commitment to quality and customer satisfaction. Companies such as Wire Mesh Factory, Dengfeng City Jinding Wire Mesh Co., Ltd., and Anping County Huaxiang Wire Mesh Products Co., Ltd. are at the forefront of this market.

These manufacturers not only provide a wide range of sizes and gauges of galvanized square wire netting but also offer customization options to meet specific needs. They cater to various sectors, including agriculture, construction, and industrial applications, ensuring their products meet diverse demands.

Additionally, many of these manufacturers focus on sustainability, employing eco-friendly practices in their production processes. This commitment to sustainability is increasingly important in today's market, where environmentally conscious consumers are looking for products that align with their values.

Conclusion

In conclusion, galvanized square wire netting is a crucial product with extensive applications in various industries. Its durability and resistance to corrosion make it a preferred choice for many, while the manufacturing process ensures consistent quality. As consumers continue to seek high-quality and sustainable products, the importance of reputable manufacturers in this space cannot be overstated. By understanding the features and benefits of galvanized square wire netting, businesses and individuals can make informed decisions that meet their specific needs, ensuring safety and reliability in their applications.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025