-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Okt . 31, 2024 02:49 Back to list

galvanized square woven wire mesh manufacturer

Understanding the Importance of Galvanized Square Woven Wire Mesh

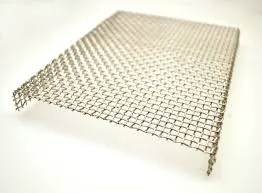

Galvanized square woven wire mesh is an essential material in various industrial and commercial applications. Its durability, corrosion resistance, and versatility make it a preferred choice among manufacturers and users alike. This article will delve into the characteristics, uses, and manufacturing process of galvanized square woven wire mesh, highlighting its significance in today’s market.

What is Galvanized Square Woven Wire Mesh?

Galvanized square woven wire mesh is created using high-quality steel wire that is woven together to form a grid-like pattern with square openings. The galvanization process involves coating the wire with a layer of zinc, which significantly enhances its resistance to rust and corrosion. This protective layer ensures that the wire mesh can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications.

Characteristics of Galvanized Square Woven Wire Mesh

1. Durability One of the primary attributes of galvanized wire mesh is its exceptional strength and longevity. This feature is critical for applications that require sturdy materials capable of withstanding stress and strain.

2. Corrosion Resistance The galvanization process protects the wire from moisture and other corrosive elements, making it ideal for outdoor use. This property ensures that the mesh maintains its structural integrity over time.

3. Versatility Galvanized square woven wire mesh can be manufactured in various degrees of thickness and mesh sizes, allowing for customization according to specific needs. This versatility is beneficial in numerous sectors, including agriculture, construction, and industrial settings.

Applications of Galvanized Square Woven Wire Mesh

galvanized square woven wire mesh manufacturer

1. Construction In the construction industry, this mesh is used for reinforcing concrete, providing additional strength and stability to structures.

2. Fencing Galvanized wire mesh is commonly employed as fencing material, providing security for residential, commercial, and agricultural properties. Its robust nature ensures a lasting barrier against intruders.

3. Industrial Use Various industries utilize galvanized square woven wire mesh for filters, sieves, and screens. Its ability to allow airflow while preventing the passage of larger particles makes it ideal for separation processes in manufacturing.

4. Agriculture Farmers use this type of wire mesh for animal enclosures, crop protection, and garden fencing. Its resistance to rust ensures that it can endure the outdoor elements without degrading.

Manufacturing Process

The manufacturing of galvanized square woven wire mesh starts with selecting high-quality steel wire, which is then processed through drawn and twisted methods to achieve the desired thickness and durability. Following this, the wire undergoes the galvanization process, where it is coated with a layer of zinc through either hot-dip galvanizing or electro-galvanizing techniques. This coating process is critical, as it determines the longevity and performance of the wire mesh. Finally, the wire is woven into the desired mesh pattern using precise machinery, ensuring uniformity and quality across the finished product.

Conclusion

Galvanized square woven wire mesh stands out as a vital material across various industries due to its impressive strength, corrosion resistance, and adaptability. Understanding its characteristics and applications can help businesses make informed decisions about their material needs. As a result, investing in quality galvanized wire mesh from reputable manufacturers is essential for ensuring durability and reliability in any project.

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025

-

Reliable Perforated Stainless Steel Sheets Custom Designs & Export

NewsJun.09,2025