-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Okt . 07, 2024 02:28 Back to list

hexagonal wire mesh factories

The Rising Demand for Hexagonal Wire Mesh Factories

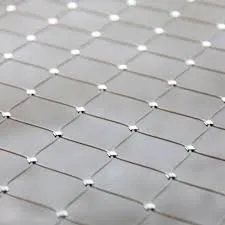

In recent years, the construction and manufacturing industries have witnessed a significant shift in the materials used for various applications. One such material that has gained popularity is hexagonal wire mesh. This versatile product, known for its hexagonal shape and strong structural integrity, has become a critical component in numerous sectors including agriculture, construction, and landscaping. As demand continues to rise, hexagonal wire mesh factories are emerging to cater to this need, fundamentally changing industry standards.

Hexagonal wire mesh, also known as chicken wire or hex mesh, is primarily made from galvanized steel or plastic-coated wire, offering durability and resistance to corrosion. Its unique shape allows for even distribution of force, making it ideal for various applications such as fencing, cages, reinforcement in concrete, and even decorative purposes. The mesh can be manufactured in multiple sizes and thicknesses, allowing it to be tailored to specific project requirements. This adaptability has fueled its appeal, leading to increased investment in the establishment of specialized factories.

One of the key advantages of hexagonal wire mesh is its lightweight nature combined with high tensile strength. This feature makes it easy to transport and install compared to other materials. In agriculture, for instance, farmers utilize hexagonal wire mesh for building enclosures for poultry, protecting livestock, and even creating effective garden boundaries. In urban planning, it is used for erosion control, retaining walls, and other landscaping projects, promoting sustainable development while enhancing the aesthetic appeal of public spaces.

hexagonal wire mesh factories

The rise of e-commerce has also contributed to the growth of hexagonal wire mesh factories. With more buyers seeking products online, factories are increasingly investing in digital marketing and direct-to-consumer sales channels. This shift allows them to reach a wider audience, including DIY enthusiasts and small businesses that require hexagonal wire mesh for specific projects. By catering to diverse consumer needs, these factories can increase production capacity and diversify their product offerings.

However, as demand grows, so does the need for sustainable manufacturing practices. Hexagonal wire mesh factories are turning towards eco-friendly materials and production methods to minimize their environmental footprint. By adopting practices like using recycled wire, reducing waste, and ensuring energy-efficient manufacturing processes, these factories are setting new industry standards. Additionally, some manufacturers are also exploring the integration of smart manufacturing technologies to enhance production efficiency, such as automation and better inventory management.

In conclusion, the burgeoning demand for hexagonal wire mesh across various industries has led to the establishment of dedicated factories tailored to meet these needs. As they adapt to market trends, embrace sustainability, and leverage technological advancements, hexagonal wire mesh factories are positioned to play a crucial role in shaping the future of construction and agriculture. The combination of durability, versatility, and eco-friendliness will likely ensure that hexagonal wire mesh remains a staple in modern industries for years to come, cementing its status as an essential building material.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025