-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dis . 24, 2024 09:19 Back to list

hog wire fence panel factories

Exploring Hog Wire Fence Panel Factories A Comprehensive Overview

Hog wire fence panels are becoming increasingly popular in various agricultural and residential settings, thanks to their versatility, strength, and aesthetic appeal. As more farmers and property owners recognize the benefits of these durable fencing solutions, the demand for hog wire fence panel factories has surged. This article will explore the essential aspects of hog wire fence panels, the manufacturing process, and the importance of quality in production.

Understanding Hog Wire Fence Panels

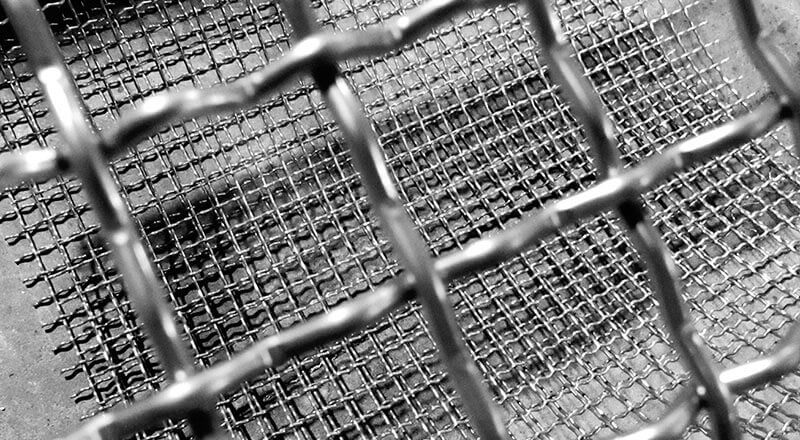

Hog wire fence panels are typically constructed from high-strength galvanized steel wire, forming a sturdy structure that can withstand the pressures of livestock management and agricultural needs. These panels are often characterized by their grid-like design, which allows for visibility while keeping animals secure. The name stems from their traditional use in hog farming, but today, they serve a wider range of applications, including deer fencing, garden fencing, and even as decorative elements in landscaping.

The popularity of hog wire fencing can be attributed to its numerous benefits. Firstly, the open grid design provides visibility and allows air circulation, which is essential for the well-being of animals. Secondly, the durability of the materials used in these panels ensures longevity and low maintenance costs. Lastly, hog wire fences can be aesthetically pleasing, complementing the natural landscape while serving a functional purpose.

The Manufacturing Process

The production of hog wire fence panels begins with the selection of high-quality raw materials

. Factories source galvanized steel wire for its resistance to rusting and corrosion, ensuring that the panels maintain their integrity over time. Once the materials are secured, the following steps typically occur1. Cutting and Shaping The steel wire is cut to specific lengths and shaped into the desired grid pattern. This process often involves advanced machinery that ensures precision in the measurements.

hog wire fence panel factories

2. Welding After the wires are arranged in the grid design, they are welded together at junction points to create a robust and seamless barrier. This step is crucial, as strong welds contribute significantly to the overall strength of the fence panels.

3. Coating and Finishing To further enhance durability, the panels may receive a protective coating. This could be additional galvanization or PVC coating, depending on the intended use and environmental factors. The finish not only protects the metal but can also provide a sleek appearance.

4. Quality Control Before the panels are packaged for distribution, quality control inspections are conducted. This ensures that each panel meets the factory's standards for strength, finish, and dimensions.

Importance of Quality in Production

Quality assurance is paramount in the manufacturing of hog wire fence panels. Factories must adhere to rigorous standards to ensure that their products can withstand the test of time and various environmental conditions. High-quality panels reduce the risk of breakage and the need for frequent replacements, making them a cost-effective choice for consumers.

Moreover, well-manufactured hog wire fences are crucial for the safety of livestock and property. A sturdy fence prevents unwanted intrusion by animals or trespassers, thereby protecting valuable assets.

Conclusion

As the demand for hog wire fence panels continues to grow, so too does the need for reliable factories that produce high-quality products. By understanding the manufacturing process and recognizing the importance of quality, consumers can make informed choices when selecting fencing solutions. Whether for agricultural purposes or enhancing a property's aesthetic appeal, hog wire fence panels remain a popular option that combines functionality with beauty.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025