-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ogo . 24, 2025 02:00 Back to list

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

Introduction to Perforated Metal Mesh Solutions

In the demanding landscape of modern industrial and architectural applications, the utility of high-performance materials is paramount. Among these, perforated metal mesh stands out as a versatile and indispensable component. Engineered by precision punching or stamping a wide array of metal sheets, this material offers an unparalleled combination of strength, ventilation, aesthetic appeal, and functional diversity. From intricate filtration systems in petrochemical facilities to robust architectural façades providing solar shading and sound attenuation, its applications are expansive. The ability to customize hole patterns, sizes, and material types makes perforated metal mesh a preferred choice for engineers, architects, and manufacturers seeking optimal performance and design flexibility. Understanding its manufacturing process, technical specifications, and application advantages is crucial for leveraging its full potential in B2B contexts. We delve into the intricacies of this material, exploring its journey from raw metal to a finished product that meets rigorous industry standards.

The demand for innovative solutions has led to significant advancements in the production of perforated metal mesh sheet products. Suppliers now offer a vast catalog, from standard designs to highly specialized configurations tailored for unique project requirements. This adaptability ensures that whether the need is for a lightweight acoustic panel or a heavy-duty screening solution, a suitable perforated metal mesh product is available, driving efficiency and sustainability across various sectors.

Manufacturing Process Flow: From Raw Material to Precision Product

The production of perforated metal mesh is a highly technical and precise process, ensuring the final product meets stringent performance and quality benchmarks. This multi-stage process leverages advanced machinery and expertise to transform flat metal sheets into components with specific functional characteristics.

- Material Selection and Preparation: The initial stage involves selecting the appropriate raw material based on the application's demands. Common materials include stainless steel (e.g., 304, 316 for metal stainless steel perforated metal mesh), carbon steel, aluminum, galvanized steel, brass, copper, and various alloys. These materials are chosen for their specific properties such as corrosion resistance, strength-to-weight ratio, conductivity, and aesthetic qualities. Sheets or coils are then prepared for the perforation process.

- Perforation (Punching/Stamping): This is the core manufacturing step. Advanced CNC-controlled punching presses or rotary pinned perforation machines are utilized to create the desired hole patterns. The process involves precisely controlled dies and punches that cut or stamp holes into the metal sheet. This method ensures consistent hole size, spacing (pitch), and pattern accuracy. For high-volume production, high-speed stamping offers efficiency, while laser cutting is employed for intricate designs or exotic materials, providing exceptional precision without mechanical stress.

- Flattening and Deburring: After perforation, the metal sheet may exhibit some distortion or burrs around the holes. A flattening process, often using roller levelers, restores the sheet's planar integrity. Deburring machines remove any sharp edges or burrs, ensuring safety and improving the material's aesthetic and functional quality.

- Shearing and Cutting: The perforated sheets are then cut to the specified dimensions or shapes required by the customer. Precision shearing machines, guillotines, or laser cutters are used to achieve accurate final product dimensions, often in formats such as custom perforated metal mesh sheet.

- Finishing and Fabrication: Depending on the application, additional finishing processes may be applied. These include degreasing, pickling, passivation (for stainless steel), powder coating, anodizing, or polishing. Fabrication services such as bending, rolling, welding, and framing are also common to create finished components or assemblies from the custom perforated metal mesh.

- Quality Control and Testing: Throughout the process, rigorous quality control measures are implemented. This includes dimensional checks, inspection of hole patterns, material integrity verification, and adherence to international testing standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials) for material properties, and ANSI (American National Standards Institute) for product specifications. These standards ensure that the service life and performance characteristics, such as corrosion resistance and energy saving capabilities, meet or exceed industry expectations. Typical service life for well-maintained stainless steel perforated mesh can exceed 20-30 years in many environments.

Figure 1: Automated Perforation Machine in Operation.

The meticulous adherence to this process flow ensures that the final perforated metal mesh product delivers superior performance in target industries such as petrochemical, metallurgy, and water supply & drainage, where corrosion resistance and efficient filtration are critical.

Technical Specifications & Parameters: Precision Engineered Performance

Understanding the technical parameters of perforated metal mesh is fundamental for effective material selection and application. These specifications dictate the material's structural integrity, filtration capabilities, airflow, and aesthetic characteristics.

Key Parameters for Perforated Metal Mesh:

- Material Type: Stainless Steel (304, 316, 316L, 430), Carbon Steel, Galvanized Steel, Aluminum (1100, 3003, 5052), Copper, Brass, Titanium, Nickel, etc. Each offers distinct properties such as corrosion resistance, strength, and weldability.

-

Hole Pattern:

- Round (most common, offering high open area and strength).

- Square (often used for architectural and screening applications).

- Slotted (ideal for drainage, sieving, or decorative purposes).

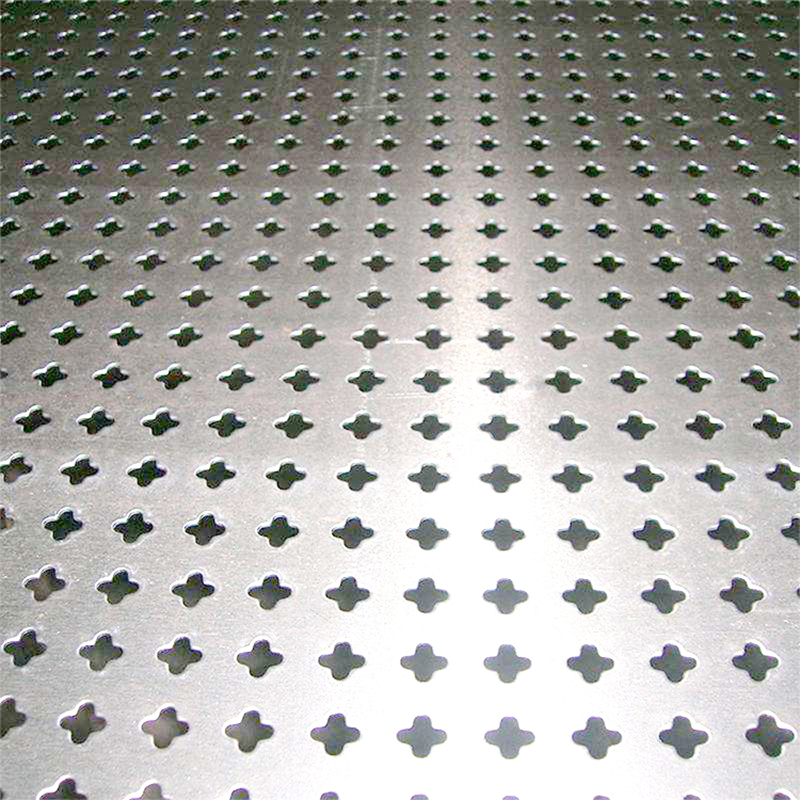

- Hexagonal, Decorative, Custom (for specialized filtration or aesthetic needs).

- Hole Size (Aperture): Diameter of round holes or width/length of slotted holes. Ranging from micro-perforations (0.5mm) to large apertures (50mm+).

- Pitch: The distance from the center of one hole to the center of the next. This, along with hole size, determines the open area.

- Thickness (Gauge): The material thickness of the metal sheet, typically ranging from 0.5mm to 10mm or more.

- Open Area Percentage: The total area of the holes divided by the total area of the sheet, expressed as a percentage. This is a critical factor for airflow, filtration efficiency, and light transmission, typically ranging from 20% to 60% depending on the application. Higher open area usually means less structural integrity but better flow.

- Margin: The unperforated area around the edges of the sheet. Can be specified as a standard margin or no margin.

Typical Product Specification Table for Perforated Metal Mesh

| Parameter | Common Range / Specification | Impact on Application |

|---|---|---|

| Material Options | SS304, SS316, Al3003, Galv. Steel, Carbon Steel | Corrosion resistance, strength, weight, cost |

| Hole Diameter | 0.5 mm to 75 mm | Filtration efficiency, airflow, visual transparency |

| Hole Pattern | Round (staggered 60°/45°), Square, Slotted | Strength, aesthetics, specific filtration needs |

| Pitch (Center-to-Center) | 1.0 mm to 100 mm (dependent on hole size) | Open area, structural stability, rigidity |

| Thickness | 0.3 mm to 12 mm | Durability, load-bearing capacity, weight |

| Open Area | 5% to 65% | Airflow, light transmission, sound absorption, filtration |

| Sheet Size | 1000x2000mm, 1250x2500mm, Custom | Installation efficiency, waste reduction |

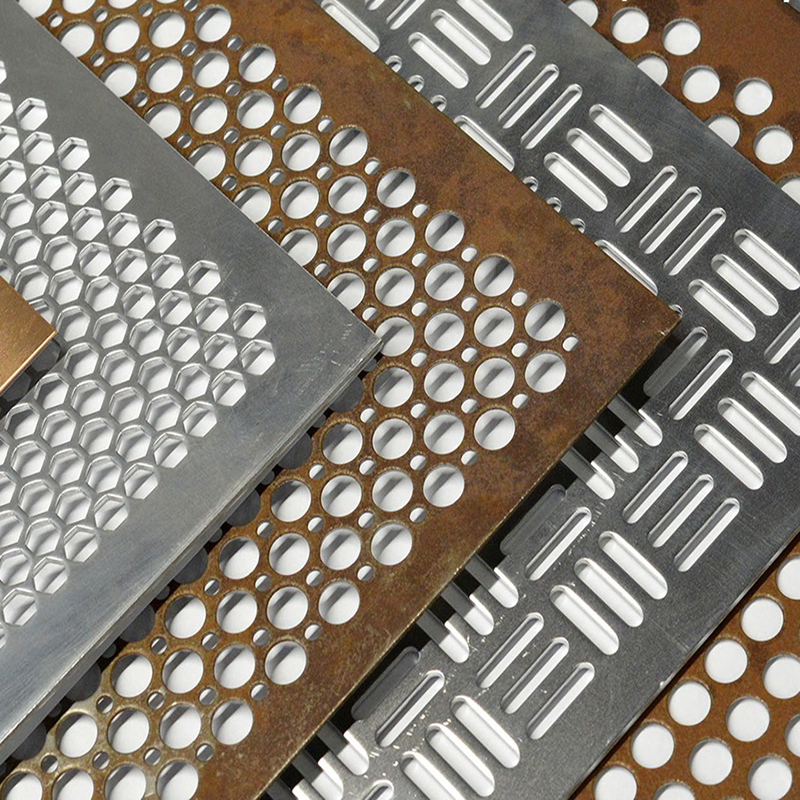

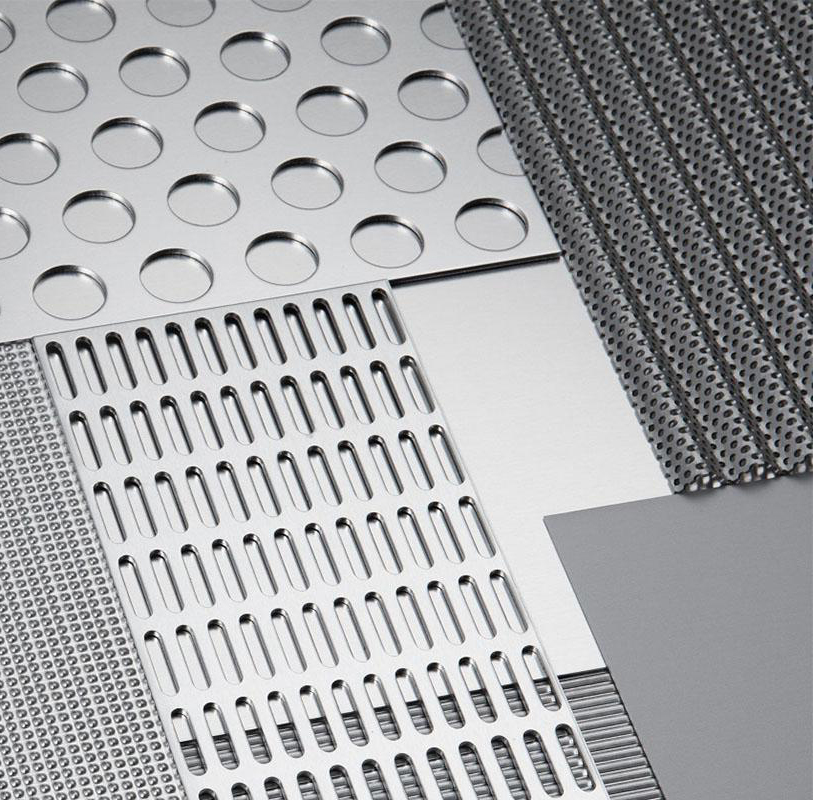

Figure 2: Close-up of various perforated patterns illustrating hole size and pitch.

These specifications are critical for ensuring optimal performance in various scenarios, from fine filtration to heavy-duty screening, underscoring the importance of precise engineering in every perforated metal mesh solution.

Key Application Scenarios & Technical Advantages

The inherent versatility and robust characteristics of perforated metal mesh make it an invaluable material across an extensive range of industrial and commercial sectors. Its ability to combine filtration, ventilation, structural support, and aesthetic appeal positions it as a go-to solution for complex engineering challenges.

Target Industries and Applications:

- Petrochemical and Chemical Processing: Used for filtration, separation, and support grids in reactors, catalytic converters, and distillation columns. The corrosion resistance of stainless steel variants ensures longevity in aggressive chemical environments.

- Metallurgy and Mining: Employed in screening and sifting processes for ores, aggregates, and other raw materials. Its durability withstands abrasive conditions and heavy loads.

- Water Supply & Drainage: Critical for water filtration systems, wastewater treatment plants, and drainage covers, preventing clogging while allowing efficient liquid flow.

- HVAC Systems: Integrated into air diffusers, grilles, and filters, enhancing airflow, reducing noise, and providing protection.

- Architecture and Construction: Widely used for building façades, sunscreens, balustrade infill panels, ceilings, and interior design elements, offering both functional benefits (solar shading, ventilation) and modern aesthetics.

- Automotive Industry: Found in speaker grilles, exhaust components, and fuel filters.

- Food and Beverage: For sorting, drying, and filtering processes where hygiene and corrosion resistance (e.g., with SS316) are paramount.

Technical Advantages in Typical Application Scenarios:

- Corrosion Resistance: Materials like stainless steel (SS304, SS316) offer exceptional resistance to rust and chemical degradation, extending service life in harsh environments, from marine applications to chemical processing plants. This significantly reduces maintenance costs and downtime.

- Energy Saving: In architectural facades, perforated metal mesh serves as an effective sunscreen, reducing heat gain in buildings and consequently lowering air conditioning loads. For HVAC, optimized open areas ensure efficient airflow with minimal pressure drop, contributing to energy efficiency.

- Sound Attenuation: When combined with acoustic materials, perforated panels can significantly reduce noise levels by absorbing sound waves, making them ideal for highway barriers, industrial environments, and public spaces.

- Filtration and Separation: Precise hole patterns allow for accurate sizing and separation of particles, crucial for industrial filters, screens, and strainers. The ability to specify minute hole sizes with high open areas ensures efficient material processing.

- Lightweight and High Strength: Despite being lightweight, particularly aluminum perforated metal mesh, the inherent structure retains significant strength, making it suitable for structural applications where weight is a concern.

- Aesthetic Versatility: The myriad of patterns, finishes, and customization options allows architects and designers to integrate perforated metal mesh seamlessly into modern designs, enhancing visual appeal while providing practical benefits.

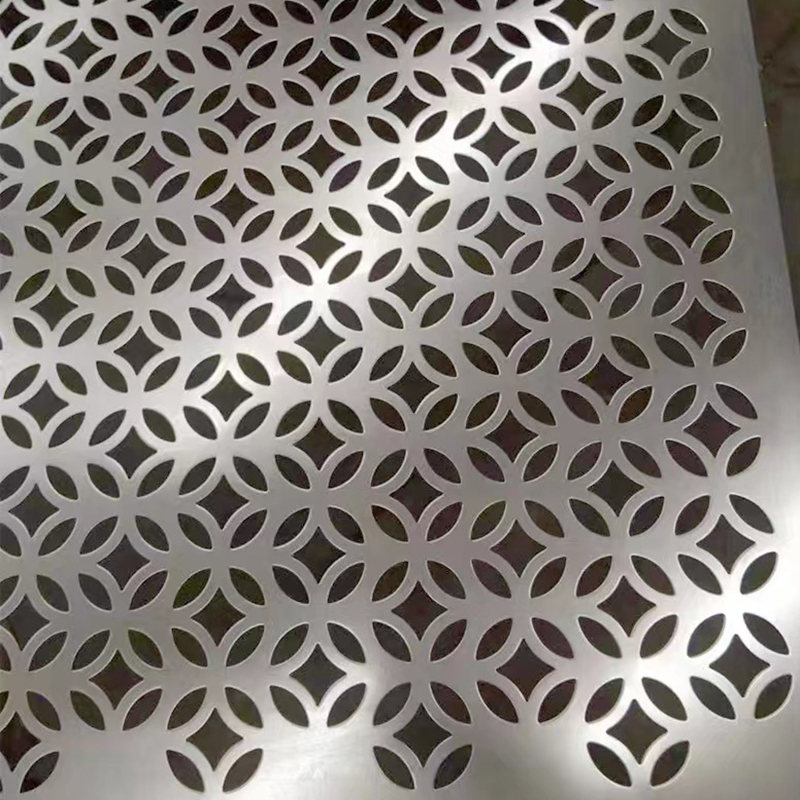

Figure 3: Perforated metal mesh integrated into an architectural facade, demonstrating aesthetic and functional benefits.

These advantages underscore why perforated metal mesh remains a cornerstone material for addressing diverse and complex engineering and design requirements across various industries.

Industry Trends & Innovation in Perforated Metal Mesh

The market for perforated metal mesh is continually evolving, driven by advancements in manufacturing technology, growing demand for sustainable solutions, and increasingly complex design requirements. These trends are shaping how manufacturers and consumers approach the material.

- Sustainable Manufacturing Practices: There is a growing emphasis on environmentally friendly production processes. This includes using recycled content in raw materials, optimizing punching processes to minimize waste, and employing energy-efficient machinery. Manufacturers are also exploring coatings and finishes with lower environmental impact.

- Advanced Material Development: Innovation extends to the materials themselves. Research into new alloys that offer enhanced corrosion resistance, lighter weight, or improved strength-to-weight ratios is ongoing. For example, specialized high-strength low-alloy steels or advanced aluminum alloys are gaining traction for critical applications.

- Digital Design and Fabrication: CAD/CAM technologies are enabling increasingly intricate and precise custom perforated metal mesh designs. This includes parametric design for generating unique patterns, 3D modeling for complex shapes, and advanced software for optimizing open area and structural performance. Laser cutting technology is also becoming more prevalent for highly detailed or irregular hole patterns.

- Integration with Smart Building Technologies: In architecture, perforated metal mesh is being integrated into intelligent building systems. For instance, panels with variable perforation zones can be used in dynamic facades that respond to environmental conditions, optimizing light, temperature, and privacy.

- Increased Demand for Aesthetic and Decorative Applications: Beyond functional requirements, the aesthetic appeal of perforated metal mesh is driving its adoption in artistic installations, retail spaces, and high-end architectural projects. The ability to create stunning visual effects through light and shadow play, along with custom finishes, is a significant growth area. This has led to a surge in demand for aesthetic wholesale perforated metal mesh.

- Focus on Micro-Perforations: For applications requiring extremely fine filtration, EMI/RFI shielding, or advanced acoustic properties, the development and production of micro-perforated sheets with hole sizes as small as 0.2mm are becoming more sophisticated and accessible.

These trends highlight a dynamic industry moving towards greater precision, sustainability, and aesthetic integration, continuously expanding the possibilities for perforated metal mesh applications.

Vendor Comparison & Customized Solutions

Selecting the right perforated metal mesh supplier is a critical decision for B2B procurement, impacting project timelines, costs, and overall product quality. A thorough vendor comparison involves evaluating several key factors beyond just price.

Factors for Choosing a Perforated Metal Mesh Supplier:

- Quality Assurance and Certifications: Look for perforated metal mesh manufacturers who adhere to international standards such as ISO 9001 (Quality Management System) and ASTM for material specifications. Certifications provide assurance of consistent product quality and reliability. Authoritative references like FDA compliance are essential for food-grade applications.

- Customization Capabilities: The ability to provide bespoke solutions is often paramount. A leading perforated metal mesh supplier should offer extensive customization in terms of material, hole size, pattern, pitch, sheet dimensions, and finishing options to meet specific project demands for custom perforated metal mesh.

- Lead Time and Fulfillment: Evaluate a vendor's typical lead times for both standard and customized orders. Reliable delivery is crucial for project scheduling. Consider their capacity for wholesale perforated metal mesh sheet orders.

- Technical Expertise and Support: A strong technical team that can assist with material selection, design optimization, and application challenges adds significant value. This includes providing detailed technical drawings and performance data.

- Pricing and Value: While not the sole determinant, competitive pricing coupled with high quality and reliable service represents true value. Consider the total cost of ownership, including potential savings from durability and reduced maintenance.

- Experience and Reputation: Look for vendors with a proven track record, positive customer feedback, and a strong market presence as perforated metal mesh exporters. Years of service in the industry and a portfolio of partner clients are good indicators of reliability.

Vendor Comparison Table (Illustrative)

| Feature | Vendor A (Example) | Vendor B (Example) | Our Capabilities (Example) |

|---|---|---|---|

| ISO 9001 Certified | Yes | No | Yes (with annual audits) |

| Custom Hole Patterns | Limited standard options | Yes, but with long lead times | Extensive, from CAD to production |

| Material Range | SS, Carbon Steel | SS, Carbon, Aluminum | SS (all grades), Aluminum, Galvanized, Copper, Brass, Specialty Alloys |

| Typical Lead Time (Custom) | 4-6 weeks | 6-8 weeks | 2-4 weeks (dependent on complexity) |

| Technical Support | Basic | Moderate | Dedicated engineering team |

| Post-Perforation Services | Minimal | Bending, Rolling | Bending, Rolling, Welding, Framing, Powder Coating, Anodizing |

Figure 4: Examples of custom perforated metal mesh fabrications for specific projects.

By carefully evaluating these factors, businesses can secure the most suitable and reliable source for their perforated metal mesh needs, whether it's for standard panels or complex custom perforated metal mesh projects.

Real-World Application Case Studies

The practical utility of perforated metal mesh is best demonstrated through its successful implementation in diverse, real-world projects. These case studies highlight the material's adaptability, technical advantages, and the impact of customized solutions.

Case Study 1: Architectural Facade for a Modern Office Building

- Challenge: A new high-rise office building in a high-sunlight zone required a facade material that could provide effective solar shading, allow natural ventilation, offer privacy, and contribute to the building's contemporary aesthetic, all while being durable and low-maintenance.

- Solution: We provided custom-fabricated aluminum perforated metal mesh panels with a staggered round hole pattern and a 45% open area. The panels were anodized in a bronze finish for enhanced corrosion resistance and visual appeal. The specific open area was chosen to balance sunlight penetration with heat reduction, contributing significantly to the building's energy efficiency.

- Outcome: The façade successfully reduced the building's cooling load by an estimated 15%, leading to substantial energy savings. Occupants reported improved comfort and natural light diffusion. The striking visual texture of the perforated metal mesh also enhanced the building's architectural identity, receiving positive feedback from both the client and the public.

Case Study 2: Industrial Filtration System for a Chemical Plant

- Challenge: A major chemical processing plant needed robust and highly corrosion-resistant filter elements for a new liquid-solid separation system. The filters had to withstand aggressive chemical reagents and high operating temperatures, ensuring efficient separation without material degradation.

- Solution: We engineered custom filter baskets and support grids from SS316L perforated metal mesh. The sheets featured a fine, uniform square hole pattern (1.5mm x 1.5mm) with a 30% open area, specifically designed for the required particle retention and flow rate. All components underwent passivation treatment to maximize corrosion resistance.

- Outcome: The SS316L perforated metal mesh components demonstrated exceptional durability and chemical resistance, significantly outperforming previous filter materials. The system achieved superior filtration efficiency, reducing downtime for filter changes and maintenance, and enhancing overall plant operational safety and productivity. The client noted a substantial reduction in operational costs over two years.

Case Study 3: Acoustic Barriers for Highway Noise Reduction

- Challenge: A municipal project aimed to reduce highway noise impacting a residential area. The solution needed to be highly effective in sound absorption, withstand outdoor elements, and be aesthetically acceptable.

- Solution: Our team supplied galvanized steel perforated metal mesh sheets, powder-coated for additional weather resistance and color matching with the urban environment. These sheets were used as the outer skin of modular acoustic barrier panels, encapsulating sound-absorbing mineral wool. The precise perforation pattern with a 25% open area was engineered to maximize sound absorption without compromising structural integrity or allowing environmental ingress to the acoustic material. This solution also proved ideal for wholesale perforated metal mesh sheet orders due to its standardized dimensions.

- Outcome: Noise monitoring data showed a significant reduction in decibel levels within the residential zone, improving quality of life for residents. The galvanized and powder-coated mesh provided excellent long-term durability against weathering, requiring minimal maintenance. This project further solidified our reputation as a reliable perforated metal mesh factory for large-scale infrastructure.

These examples underscore the critical role of expertly manufactured and customized perforated metal mesh in solving real-world engineering and design challenges, consistently delivering superior performance and long-term value.

Trust & Support: Our Commitment to You

At the core of our operations is an unwavering commitment to customer trust, transparency, and comprehensive support. We understand that for B2B clients, reliability and clear communication are as crucial as product quality when sourcing perforated metal mesh.

Frequently Asked Questions (FAQ):

- Q: What are the typical lead times for custom perforated metal mesh orders?

- A: Standard product lead times typically range from 1-2 weeks. For highly customized perforated metal mesh solutions, lead times generally range from 2-4 weeks, depending on material availability, complexity of perforation, and required finishing processes. We provide clear estimates at the time of quotation.

- Q: What materials can be perforated?

- A: We can perforate a wide array of materials, including various grades of stainless steel (304, 316, 316L), carbon steel, galvanized steel, aluminum (1100, 3003, 5052), copper, brass, and specialty alloys. Our technical team can advise on the best material for your specific application and environment.

- Q: Can you handle large-volume wholesale orders?

- A: Yes, our advanced manufacturing facility is equipped to manage large-volume wholesale perforated metal mesh orders efficiently, maintaining consistent quality and adhering to agreed-upon fulfillment schedules. We have robust logistics for both domestic and international shipments.

- Q: What quality certifications do you hold?

- A: We operate under an ISO 9001 certified Quality Management System, ensuring all products, including our perforated metal mesh, meet strict quality control parameters from raw material sourcing to final inspection. We also comply with relevant ASTM and ANSI standards where applicable.

Lead Time & Fulfillment Details:

Our production capabilities are optimized for efficiency without compromising precision. For standard perforated metal mesh products, lead times are typically 7-10 business days. For customized orders, including those requiring specific materials, hole patterns, or post-perforation fabrication, lead times range from 15-20 business days. Expedited services may be available upon request. We leverage an integrated logistics network to ensure timely and secure delivery, whether for local distribution or international exports. Detailed fulfillment plans are provided with every order confirmation.

Warranty Commitments:

We stand behind the quality of our perforated metal mesh products. All materials and workmanship are warranted to be free from defects under normal use and service for a period of one (1) year from the date of shipment. This warranty covers manufacturing defects and material integrity according to agreed-upon specifications and relevant industry standards. Full warranty terms and conditions are available upon request.

Customer Support Information:

Our dedicated customer support team is available to assist with inquiries, technical advice, order tracking, and after-sales service. We pride ourselves on responsive and knowledgeable support.

- Email: sales@example.com (replace with actual email)

- Phone: +1 (XXX) XXX-XXXX (replace with actual phone number)

- Business Hours: Monday - Friday, 9:00 AM - 5:00 PM (Local Time)

Figure 5: Our team preparing a custom order for shipment, emphasizing precision and care.

Your project's success is our priority. Partner with us for reliable perforated metal mesh solutions backed by comprehensive support and a commitment to excellence.

Conclusion

The journey through the intricate world of perforated metal mesh reveals a material of extraordinary versatility and essential functionality. From its precise manufacturing processes and rigorous quality control to its expansive array of technical specifications and application advantages, perforated metal mesh stands as a critical component in countless industrial, architectural, and design projects. Its capacity for customization, coupled with inherent properties like corrosion resistance, energy efficiency, and aesthetic appeal, positions it as an indispensable solution for demanding B2B needs. As industries evolve and technical challenges become more complex, the innovation in perforated metal mesh continues to offer sustainable, high-performance, and visually compelling solutions that drive progress and efficiency. Choosing a trusted partner with expertise in custom fabrication, adherence to international standards, and robust customer support ensures that every project leverages the full potential of this exceptional material.

Authoritative References

- ISO (International Organization for Standardization). ISO 9001:2015 - Quality management systems - Requirements.

- ASTM International. (Various standards relevant to metal sheets, e.g., ASTM A240 for Stainless Steel Plate, Sheet, and Strip; ASTM B209 for Aluminum and Aluminum-Alloy Sheet and Plate).

- ANSI (American National Standards Institute). (Various standards relevant to product specifications).

- "The Perforated Metal Handbook" by the Perforated Metal Producers Association (PMPA), a division of the North American Metal Perforators Association (NAMPA).

- Architectural Record. "Perforated Metal: Art and Function in Facades." (Journal article, specific issue may vary).

This is the last article

-

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

NewsAug.24,2025

-

Durable Metal Mesh Fabric For Glass Laminated | Strength & Style

NewsAug.23,2025

-

Hexagonal Wire Mesh: Durable Galvanized & PVC Coated Rolls

NewsAug.22,2025

-

Durable Hexagonal Gabions for Erosion Control & Retaining Walls

NewsAug.21,2025

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025