-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 20, 2025 03:02 Back to list

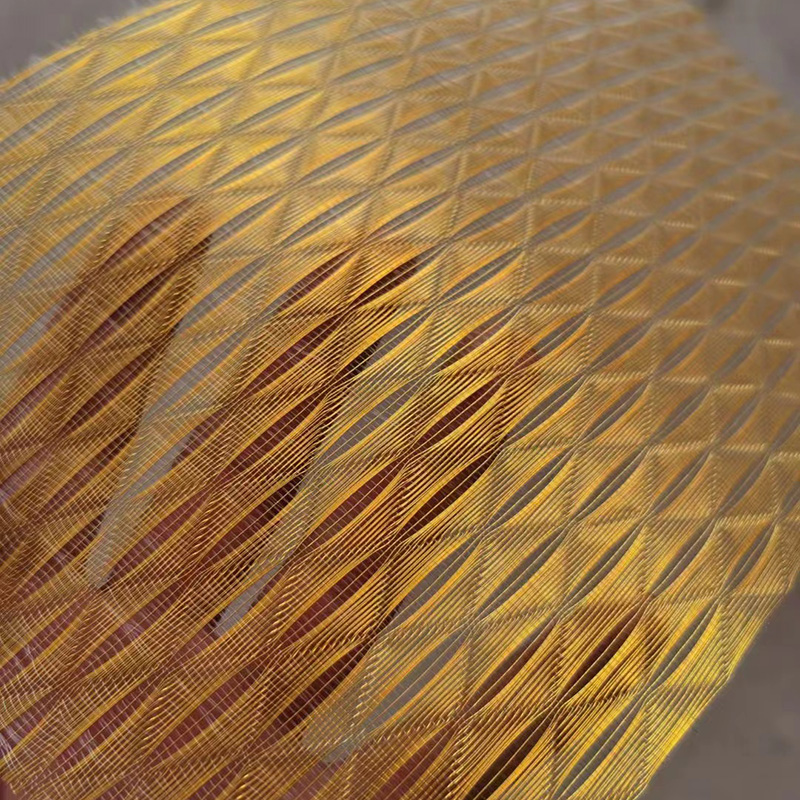

metal stainless steel perforated metal mesh

In the realm of architectural and industrial design, perforated metal panels have become indispensable assets, offering a blend of aesthetic appeal and functional brilliance. Their versatile nature makes them suitable for a variety of applications, ranging from building facades to interior partitions and acoustical ceilings. This article explores the benefits and uses of perforated metal panels, underscoring their role as a modern engineering marvel.

Perforated metal panels also contribute to acoustic enhancement in diverse settings, from concert halls to office spaces. These panels can be engineered to absorb sound, minimizing noise and creating more peaceful environments. This capability is particularly beneficial in urban areas where noise pollution is a significant concern. By improving acoustics, perforated metal panels contribute to a higher quality of life and workplace productivity. Safety and security are also strengthened with the use of perforated metal panels. They can serve as protective barriers without compromising visibility, making them suitable for applications such as stair railings, balcony fencing, and even security screens. Their strength, combined with customizable transparency levels, enables the creation of safe yet open environments. Sustainability is increasingly at the forefront of design considerations. The production processes of perforated metal panels often embrace recyclable materials, which align with green building strategies. These panels help in reducing the carbon footprint of construction projects and promote environmental responsibility—an essential criterion for stakeholders aiming to achieve sustainability certifications like LEED. The expertise required to effectively utilize perforated metal panels involves understanding their material properties, environmental impacts, and application contexts. Engineers and architects must collaborate closely to address these considerations, ensuring performance standards are met while achieving the desired aesthetic effect. This interdisciplinary collaboration is crucial for harnessing the full potential of these panels. In conclusion, perforated metal panels stand as a testament to the fusion of design ingenuity and practical utility. Their adaptability, combined with their sustainability and technical benefits, explains their widespread use across various sectors. From enhancing architectural beauty to improving energy efficiency and acoustics, perforated metal panels prove their worth as a multifaceted tool in modern design and construction. As industries continually evolve, the role of perforated metal panels will undoubtedly expand, reinforcing their status as a cornerstone in contemporary design solutions.

Perforated metal panels also contribute to acoustic enhancement in diverse settings, from concert halls to office spaces. These panels can be engineered to absorb sound, minimizing noise and creating more peaceful environments. This capability is particularly beneficial in urban areas where noise pollution is a significant concern. By improving acoustics, perforated metal panels contribute to a higher quality of life and workplace productivity. Safety and security are also strengthened with the use of perforated metal panels. They can serve as protective barriers without compromising visibility, making them suitable for applications such as stair railings, balcony fencing, and even security screens. Their strength, combined with customizable transparency levels, enables the creation of safe yet open environments. Sustainability is increasingly at the forefront of design considerations. The production processes of perforated metal panels often embrace recyclable materials, which align with green building strategies. These panels help in reducing the carbon footprint of construction projects and promote environmental responsibility—an essential criterion for stakeholders aiming to achieve sustainability certifications like LEED. The expertise required to effectively utilize perforated metal panels involves understanding their material properties, environmental impacts, and application contexts. Engineers and architects must collaborate closely to address these considerations, ensuring performance standards are met while achieving the desired aesthetic effect. This interdisciplinary collaboration is crucial for harnessing the full potential of these panels. In conclusion, perforated metal panels stand as a testament to the fusion of design ingenuity and practical utility. Their adaptability, combined with their sustainability and technical benefits, explains their widespread use across various sectors. From enhancing architectural beauty to improving energy efficiency and acoustics, perforated metal panels prove their worth as a multifaceted tool in modern design and construction. As industries continually evolve, the role of perforated metal panels will undoubtedly expand, reinforcing their status as a cornerstone in contemporary design solutions.

Next:

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025