-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dis . 07, 2024 04:47 Back to list

steel grating canal cover factories

Steel Grating Canal Covers An Overview of Factories and Manufacturing Processes

In recent years, the demand for durable and efficient drainage solutions has increased significantly due to urbanization and infrastructural development. Among these solutions, steel grating canal covers have emerged as a popular choice for both commercial and residential applications. This article explores the manufacturing processes of steel grating canal covers, the types of factories involved, and the key advantages these products offer.

What are Steel Grating Canal Covers?

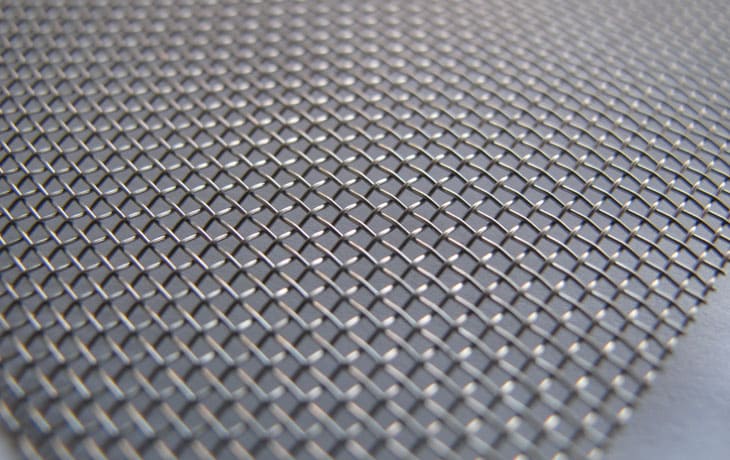

Steel grating canal covers are load-bearing structures designed to cover drainage channels while allowing for the passage of water. Constructed from high-quality steel, these covers are characterized by their grid-like structure, which provides strength and stability while minimizing weight. The open design ensures that water can flow freely into drainage systems, helping to prevent flooding and maintain sanitary conditions.

Types of Factories Involved

1. Manufacturing Facilities Specialized factories are equipped to produce steel grating canal covers. These facilities utilize advanced machinery and technology to cut, weld, and finish steel materials. They have dedicated sections for various stages of production, including raw material processing, grating formation, and surface treatment.

2. Steel Fabrication Shops These smaller-scale operations focus on customizing steel grating covers to meet specific client requirements. Fabrication shops often handle bespoke projects, allowing for tailored designs and sizes that standard factories may not offer.

3. Recycling Plants An increasingly important sector in the production of steel grating is recycling. As environmental concerns grow, many manufacturers are turning to recycled steel to produce their products. This not only reduces the carbon footprint associated with new steel production but also lowers raw material costs.

Manufacturing Processes

The manufacturing process of steel grating canal covers involves several critical steps

1. Material Selection The first step is selecting the right grade of steel, which is essential for durability and resistance to environmental factors. Galvanized steel is often favored due to its corrosion-resistant properties.

2. Cutting and Shaping Once the material is procured, it undergoes cutting and shaping. Advanced laser cutting machines and CNC (Computer Numerical Control) technology are typically employed to ensure precise and consistent dimensions.

steel grating canal cover factories

3. Welding and Assembly After the individual components are cut, they are assembled and welded together. This stage requires skilled labor to ensure strong and reliable joints. Automated welding machines are commonly used to increase efficiency and maintain high standards.

4. Surface Treatment Following assembly, the covers are treated to enhance their durability. This process may include galvanizing, powder coating, or painting to protect against rust and wear.

5. Quality Control Before any steel grating canal cover leaves the factory, it undergoes rigorous quality control checks. This includes testing for strength, load-bearing capacity, and resistance to environmental factors. Only products that meet strict standards are approved for distribution.

Advantages of Steel Grating Canal Covers

Steel grating canal covers offer numerous advantages that contribute to their popularity in construction and infrastructure projects

1. Durability Steel is inherently strong and can withstand significant loads, making these covers suitable for heavy traffic areas.

2. Safety The open design of grating allows for effective drainage, reducing the risk of flooding and pooling water, as well as preventing accidents associated with slippery surfaces.

3. Low Maintenance Steel grating canal covers are easy to maintain compared to traditional solid covers. They are resistant to damage from UV rays, chemicals, and weather conditions.

4. Recyclability Steel is a sustainable material that can be recycled, making these covers an environmentally friendly choice.

5. Customizable Factories can produce steel grating canal covers in various shapes, sizes, and load ratings, accommodating the specific needs of different projects.

Conclusion

Steel grating canal covers represent a robust solution for modern drainage systems. The factories that manufacture these products play a crucial role in ensuring quality and efficiency. As urban planning continues to evolve, the importance of reliable drainage solutions like steel grating canal covers cannot be overstated, paving the way for safer and more sustainable infrastructure development.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025