-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 09, 2025 14:10 Back to list

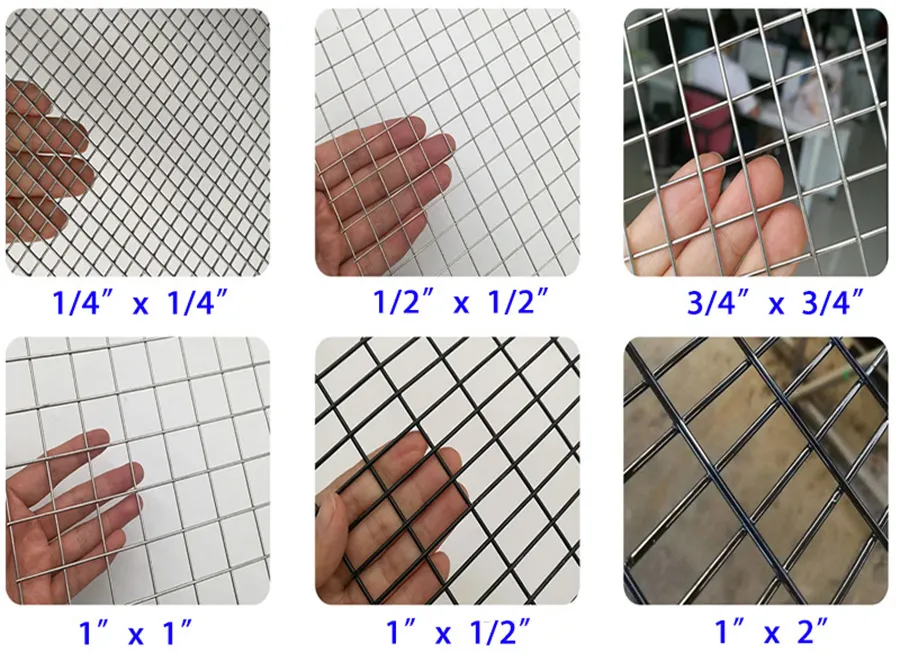

welded wire mesh

In the ever-evolving landscape of construction and infrastructure development, one product that stands out for its incredible utility and adaptability is welded wire mesh. This modern marvel has revolutionized how builders and engineers approach complex projects, offering unparalleled benefits that cater to the rigorous demands of the industry.

In the realm of authoritativeness, leading industry bodies have long endorsed welded wire mesh as a superior reinforcement solution. Its contribution to improving safety and longevity of structures is backed by rigorous testing and certification. Studies have shown that structures reinforced with welded wire mesh exhibit superior performance under stress, showcasing its authority as a critical component in modern construction practices. Trustworthiness is a cornerstone of the welded wire mesh industry. Suppliers and manufacturers adhere to top-tier quality control processes, ensuring that every piece of mesh delivered to a job site meets the highest safety and performance criteria. Choosing welded wire mesh from reputable providers guarantees reliability, instilling confidence in contractors and developers alike. The environmental impact of construction materials is an increasing concern, and welded wire mesh excels in this area as well. Its production involves less waste compared to traditional reinforcement methods, and the steel used is often sourced from recycled materials. This commitment to sustainability not only enhances the mesh's appeal as an eco-friendly option but also aligns with global efforts to reduce carbon footprints in construction activities. Ultimately, the decision to use welded wire mesh transcends its mechanical properties. It's about adopting a tried-and-tested solution that embodies precision, reliability, and efficiency. As construction demands grow more complex, welded wire mesh remains a superior choice, bridging the gap between innovative engineering and environmentally responsible practices. The collective experience and expertise behind its development reinforce its status as a mainstay in the industry, providing excellence and trustworthiness in every strand.

In the realm of authoritativeness, leading industry bodies have long endorsed welded wire mesh as a superior reinforcement solution. Its contribution to improving safety and longevity of structures is backed by rigorous testing and certification. Studies have shown that structures reinforced with welded wire mesh exhibit superior performance under stress, showcasing its authority as a critical component in modern construction practices. Trustworthiness is a cornerstone of the welded wire mesh industry. Suppliers and manufacturers adhere to top-tier quality control processes, ensuring that every piece of mesh delivered to a job site meets the highest safety and performance criteria. Choosing welded wire mesh from reputable providers guarantees reliability, instilling confidence in contractors and developers alike. The environmental impact of construction materials is an increasing concern, and welded wire mesh excels in this area as well. Its production involves less waste compared to traditional reinforcement methods, and the steel used is often sourced from recycled materials. This commitment to sustainability not only enhances the mesh's appeal as an eco-friendly option but also aligns with global efforts to reduce carbon footprints in construction activities. Ultimately, the decision to use welded wire mesh transcends its mechanical properties. It's about adopting a tried-and-tested solution that embodies precision, reliability, and efficiency. As construction demands grow more complex, welded wire mesh remains a superior choice, bridging the gap between innovative engineering and environmentally responsible practices. The collective experience and expertise behind its development reinforce its status as a mainstay in the industry, providing excellence and trustworthiness in every strand.

Next:

Latest news

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025