-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 17, 2024 05:59 Back to list

10 gauge wire mesh manufacturer

The Importance of 10% Gauge Wire Mesh A Comprehensive Overview

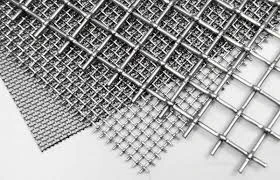

Wire mesh is an essential component in various industries, from construction and agriculture to manufacturing and landscaping. Among the various types of wire mesh available, 10% gauge wire mesh stands out due to its unique combination of strength, versatility, and affordability. This article delves into the characteristics, applications, and manufacturing processes of 10% gauge wire mesh, emphasizing its importance in today's market.

Understanding 10% Gauge Wire Mesh

Gauge refers to the diameter of the wire used in the mesh, with a lower gauge number indicating a thicker wire. In the case of 10% gauge wire mesh, the wire diameter typically ranges around 0.102 inches (approximately 2.59 mm). This thickness provides excellent durability, making it ideal for various applications requiring both strength and flexibility.

The mesh is typically woven or welded, depending on its intended use. Woven wire mesh is crafted from individual wires that are interlaced to create a flexible yet sturdy structure, while welded wire mesh is made by welding intersections of wires, resulting in a rigid and robust assembly. Both types offer distinct advantages, making 10% gauge wire mesh a versatile choice for manufacturers and contractors alike.

Applications of 10% Gauge Wire Mesh

The use of 10% gauge wire mesh spans multiple industries. Here are a few notable applications

1. Construction In the construction industry, this wire mesh is commonly utilized as reinforcement in concrete and masonry projects. Its strength helps to prevent cracks and structural failures, providing a solid foundation for buildings, bridges, and other infrastructures.

2. Agriculture In agriculture, 10% gauge wire mesh is often used for fencing, animal enclosures, and crop protection. Its durability ensures that it can withstand the elements and the pressures of livestock, making it a reliable choice for farmers seeking long-lasting solutions.

10 gauge wire mesh manufacturer

3. Manufacturing Manufacturers frequently incorporate this wire mesh in creating various products, from baskets and containers to HVAC filters. The strength of the mesh allows for practical applications in environments that require durability and resistance to wear and tear.

4. Landscaping In landscaping and gardening, 10% gauge wire mesh is used for erosion control, decorative fencing, and plant support. Its versatility in design allows for creative landscaping solutions that maintain both functionality and aesthetics.

The Manufacturing Process

The manufacturing of 10% gauge wire mesh involves several steps, each crucial to ensuring the final product meets industry standards. Initially, high-quality steel wire is selected for its tensile strength. The wire is then drawn into the desired gauge size, which is a critical step that determines the final thickness.

Afterward, the wire is either woven or welded into mesh patterns. For woven mesh, the wires are interlaced in a specific geometric pattern to maintain flexibility, while welded mesh involves the use of electrical currents to fuse the wires at intersections. Once the mesh is formed, it undergoes quality checks to ensure it meets the required specifications.

Finally, the mesh may be coated or galvanized to enhance its resistance to corrosion and increase its lifespan. This coating process further solidifies the mesh’s suitability for use in various environments, including those exposed to moisture and harsh weather conditions.

Conclusion

In conclusion, 10% gauge wire mesh is a vital component across many sectors due to its strength, versatility, and adaptability. Its applications range from construction to agriculture, making it an indispensable tool for professionals and enthusiasts alike. The manufacturing process ensures that each piece of wire mesh adheres to stringent quality standards, guaranteeing its durability and effectiveness. As industries continue to evolve, the demand for high-quality wire mesh, particularly 10% gauge options, is likely to grow, paving the way for innovative applications and solutions in the future. Whether you require it for practical uses or creative projects, investing in quality wire mesh is a decision that will provide lasting benefits.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025