-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 19, 2024 09:02 Back to list

Aluminum Expanded Metal Mesh Production Techniques and Applications Guide

Exploring the World of Aluminum Expanded Metal Mesh The Leading Factory Insights

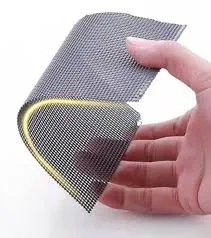

In the realm of architectural design and industrial applications, aluminum expanded metal mesh has emerged as a popular choice due to its unique attributes and versatility. This material, created through a process that transforms flat aluminum sheets into durable, lightweight mesh by slitting and stretching, offers an ideal solution for various applications ranging from facades to filtration systems. As factories specializing in aluminum expanded metal mesh expand in size and capability, understanding their processes and products is essential for consumers and professionals alike.

The Manufacturing Process

The production of aluminum expanded metal mesh begins with high-quality aluminum sheets, which are carefully selected for their strength and lightweight properties. The manufacturing process involves two primary steps slitting and stretching. Initially, the aluminum sheet is slitted with precision tools, creating a pattern of incisions. Following this, the sheet is stretched to create the characteristic diamond-shaped openings, giving the mesh its strength while allowing for a reduction in weight.

This method not only maximizes the strength-to-weight ratio of the metal but also ensures that the resultant mesh is far more economical than solid sheets when it comes to material usage. Different sizes and shapes of openings can be produced, providing designers with flexibility in their projects. The ability to customize the size and shape of the mesh is one of the key advantages these factories can offer, catering to specific client requirements in industries like construction, automotive, and agriculture.

Advantages of Aluminum Expanded Metal Mesh

The advantages of aluminum expanded metal mesh are vast. Firstly, the mesh is incredibly lightweight, making it easier to handle and install while maintaining structural integrity. Additionally, aluminum is known for its resistance to corrosion, particularly when treated appropriately, which makes this kind of mesh suitable for both indoor and outdoor applications.

Moreover, the open structure of the mesh allows for excellent airflow and visibility, making it perfect for use in decorative applications, such as architectural facades and privacy screens. It can also serve functional purposes, such as in grating for walkways, fencing panels, and even in sound barriers on busy roadways, demonstrating its versatility across multiple sectors.

aluminum expanded metal mesh factory

Sustainability in Manufacturing

Leading aluminum expanded metal mesh factories are increasingly focusing on sustainable practices. The aluminum used in the production is often recycled, making the production process more eco-friendly. Moreover, the efficiency of using expanded metal minimizes waste compared to other metal manufacturing processes. The resulting lightweight material also contributes to energy savings in transportation and application, aligning with global efforts toward sustainability.

Applications of Aluminum Expanded Metal Mesh

The applications of aluminum expanded metal mesh are virtually limitless. In construction, it is increasingly being used for architectural facades, safety barriers, and decorative elements, lending a modern touch to buildings while enhancing functionality. The automotive industry utilizes aluminum expanded metal mesh for components like grills, engine covers, and interior décor, taking advantage of its lightweight yet robust nature.

Industrial settings often employ this mesh for filters, protective guards, and ventilation applications, while agricultural sectors utilize it in storage, fencing, and animal enclosures due to its durability and resistance to the elements.

Conclusion

As the demand for aluminum expanded metal mesh continues to grow, factories specializing in its production are innovating to meet the diverse needs of various industries. The combination of strength, lightweight properties, and corrosion resistance makes aluminum expanded metal mesh a go-to choice for architects, engineers, and designers. From aesthetic enhancements to practical applications, its versatility is unmatched. With advancements in sustainable manufacturing and customization capabilities, the future of aluminum expanded metal mesh looks promising, ensuring its place in modern architecture and industrial design for years to come. For anyone considering its use, the insights gained from understanding the manufacturing processes and applications of aluminum expanded metal mesh can lead to informed and effective decisions in their projects.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025