-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 10, 2024 17:21 Back to list

Aluminum Perforated Metal Sheet Supplier for Versatile Applications and Custom Designs

Aluminum Perforated Metal Sheet Manufacturers A Comprehensive Overview

Aluminum perforated metal sheets have become increasingly popular across various industries due to their unique combination of lightweight properties, durability, and aesthetic appeal. As versatile materials, they find applications in architectural design, industrial manufacturing, filtration systems, and many other fields. With a growing demand for these products, a multitude of manufacturers have emerged, each offering a range of options to cater to diverse needs.

Understanding Aluminum Perforated Metal Sheets

Aluminum perforated metal sheets are created by puncturing a sheet of aluminum with a series of holes of various shapes and sizes. This process can be customized to produce specific patterns that cater to design or functional requirements. The holes can be round, square, slotted, or even custom-shaped, allowing for creativity in design and functionality. The primary benefits of aluminum are its lightweight nature, resistance to corrosion, and ability to withstand various environmental conditions, making it ideal for both indoor and outdoor applications.

Key Applications

1. Architectural Uses Perforated aluminum sheets are frequently used in architectural projects, such as facades, balcony railings, and ceiling panels. They not only enhance aesthetic value but also provide ventilation, allowing for airflow while maintaining privacy.

2. Industrial Applications In industrial settings, these sheets can be utilized for safety guards, machinery covers, and conveyor systems. Their strength and durability make them suitable for demanding environments, while the perforations can reduce weight and facilitate the passage of light or air.

3. Filtration and Separation Perforated aluminum is also used in filtration applications, where precise hole sizes are crucial for separating particles in various processes. The material’s resistance to chemicals and moisture further enhances its utility in these systems.

Choosing a Manufacturer

aluminum perforated metal sheet manufacturer

When selecting a manufacturer for aluminum perforated metal sheets, several factors should be considered

- Quality Standards Look for manufacturers who adhere to international quality standards, ensuring that their products meet specific durability and safety requirements.

- Customization Options The ability to customize hole size, pattern, and sheet thickness is essential for meeting specific project requirements. A good manufacturer should offer flexible options to match client specifications.

- Technical Expertise Manufacturers with a solid background in engineering and design can assist in optimizing the product for specific applications, providing valuable insights into material selection and design considerations.

- Production Capabilities Evaluate the manufacturer’s production capabilities, including equipment and technology. Advanced machinery can enable precision drilling and cutting, ensuring consistent quality across batches.

- Customer Service Effective communication is vital in any manufacturing relationship. Choose a supplier known for responsive customer service, ready to assist with design questions, technical support, and order logistics.

Sustainability Considerations

In today’s market, sustainability is a key concern. Many manufacturers are adopting eco-friendly practices in sourcing and production. Aluminum is a highly recyclable material, and sustainable manufacturers typically have programs in place to minimize waste and energy consumption during production.

Conclusion

Aluminum perforated metal sheets are an indispensable resource in numerous industries, providing solutions that combine functionality with innovative design. The selection of a reliable manufacturer is crucial in ensuring that the sheets not only meet functional requirements but also align with aesthetic goals. By considering factors such as quality, customization, technical expertise, and sustainability, businesses can establish valuable partnerships that enhance their projects and overall success in the market. As the demand for perforated aluminum continues to grow, staying informed about leading manufacturers will enable companies to make educated decisions, ultimately leading to superior results in their applications.

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

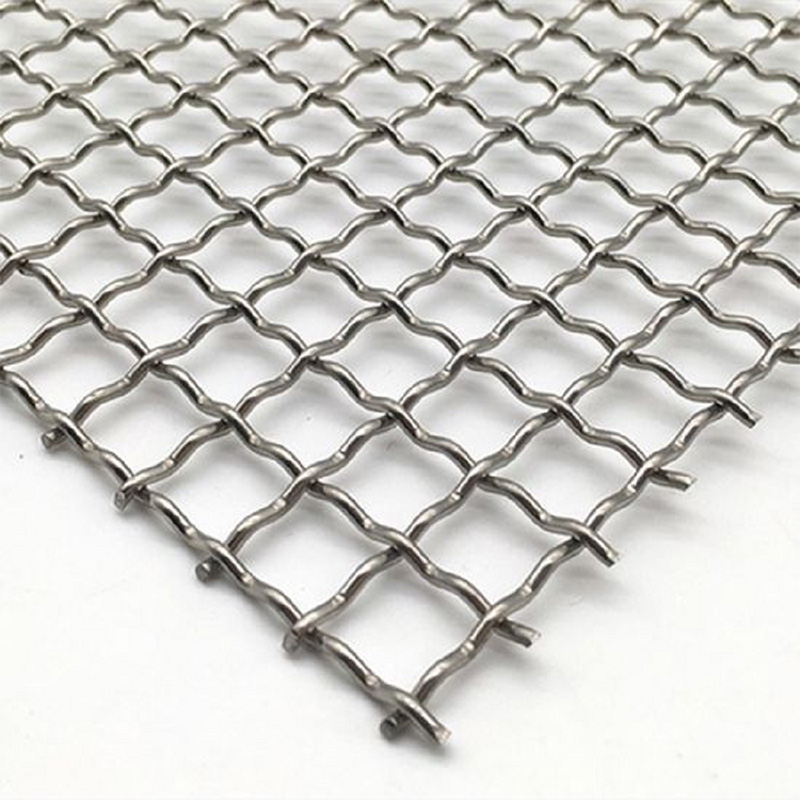

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025