-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 12, 2025 08:20 Back to list

Anti Bird Spikes Exporter | Durable, Humane Bird Control Solutions

The Strategic Role of anti bird spikes exporter in Modern Infrastructure Protection

In the rapidly evolving landscape of urban development and industrial infrastructure, managing avian pest control is a critical aspect of maintenance and operational efficiency. Birds, while integral to ecosystems, can cause significant damage to buildings, machinery, and public health through their droppings and nesting habits. A professional anti bird spikes exporter plays a pivotal role in supplying high-quality, durable solutions designed to protect a wide array of structures from the detrimental effects of bird perching and nesting. This comprehensive guide delves into the intricate world of anti-bird spike manufacturing, technical specifications, application advantages, and the crucial factors B2B clients consider when selecting a reliable supplier to safeguard their investments.

Manufacturing Excellence: The Process Flow of Anti-Bird Spikes

The production of high-performance anti-bird spikes, critical for any reputable anti bird spikes exporter, involves a series of meticulously controlled stages, ensuring product integrity, optimal performance, and longevity. This rigorous process underpins the reliability and effectiveness demanded by diverse industrial applications, from petrochemical plants to urban skyscrapers.

Material Selection and Preparation

The foundation of a superior bird spike lies in its material composition. Typically, high-grade stainless steel (e.g., SUS304 for general applications, SUS316 for enhanced corrosion resistance in marine or highly corrosive environments) or durable, UV-stabilized polycarbonate are chosen. These materials are selected for their inherent resistance to environmental degradation, including harsh UV radiation, extreme temperatures, and chemical exposure. For stainless steel, raw coils or rods are sourced, while polycarbonate involves granule preparation for precision injection molding.

Precision Manufacturing Processes

- Steel Spike Production (CNC Machining & Forming): Stainless steel wires are precisely cut and sharpened using advanced Computer Numerical Control (CNC) machinery to ensure uniform tip geometry and consistent length. The base strips, often made from galvanized steel or stainless steel, are formed via stamping or specialized bending processes. These individual spikes are then securely attached to the base.

- Polycarbonate Base & Spike Molding: UV-stabilized polycarbonate granules are fed into high-pressure injection molding machines. This process creates the robust, flexible base strips, either with integrated spikes or with specific sockets designed for steel spike insertion, ensuring consistent dimensions and structural integrity across batches.

- Assembly and Bonding: For hybrid models (stainless steel spikes on polycarbonate bases), the pre-cut and sharpened stainless steel wires are inserted into the molded polycarbonate bases. Advanced bonding agents, often industrial-grade UV-cured adhesives, are used to securely anchor the spikes, preventing dislodgement even under significant environmental stress or physical impact.

- Finishing and Surface Treatment: Stainless steel components may undergo passivation, a chemical process that enhances their corrosion resistance and achieves a uniform, clean finish. Polycarbonate components are meticulously inspected for any molding flash and trimmed as necessary to ensure a smooth, professional appearance.

Quality Control and Testing Standards

Adherence to international standards is paramount for any reputable anti bird spikes exporter to guarantee performance and compliance. Key testing protocols include:

- Material Composition Analysis: Spectroscopic analysis is conducted to verify alloy grades (e.g., conforming to ASTM A240 for stainless steel) and ensure the absence of impurities in polycarbonate.

- Tensile Strength Testing: Spikes and bases undergo rigorous testing to ensure they can withstand significant force and environmental loads (e.g., strong winds, incidental impacts) without breaking or deforming, crucial for long-term structural integrity.

- UV Resistance Testing: Accelerated weathering tests (e.g., according to ASTM G154 or ISO 4892) are performed on polycarbonate components to simulate prolonged outdoor exposure, guaranteeing protection against degradation, yellowing, and brittleness.

- Corrosion Resistance Testing: Salt spray tests (e.g., ISO 9227, ASTM B117) are conducted on stainless steel products to evaluate their performance and integrity in corrosive environments, replicating conditions in coastal or industrial zones.

- Adhesion Strength Testing: For hybrid systems, specialized tests ensure the robust bond between steel spikes and the polycarbonate base can withstand environmental factors and mechanical stresses over time.

- Dimensional Accuracy: Precision measurements using advanced calipers and gauges confirm that spikes meet specified lengths, widths, and spike density, ensuring consistent and effective coverage.

These stringent quality checks ensure a service life typically exceeding 10 years for polycarbonate variants and often 15-25 years for stainless steel solutions, depending on specific environmental conditions and maintenance practices.

Target Industries and Application Advantages

Anti-bird spikes are indispensable across a multitude of sectors, providing essential protection:

- Petrochemical & Energy: Protecting sensitive equipment, pipelines, and solar panel arrays from corrosive droppings and nesting debris. Key advantages include superior corrosion resistance (especially with SUS316) and prevention of costly maintenance, ensuring operational continuity and safety.

- Metallurgy & Heavy Industry: Securing structural beams, eaves, and signage where bird presence can compromise safety, cleanliness, or lead to equipment malfunction. The robust construction provides long-term, low-maintenance solutions in demanding environments.

- Water Supply & Drainage: Safeguarding water treatment plants, reservoirs, and pumping stations from contamination and blockage caused by avian activity. These solutions are critical for maintaining hygiene and preventing infrastructure damage.

- Commercial & Residential: Essential for building facades, ledges, balconies, and air conditioning units to prevent property damage, maintain aesthetic appeal, and mitigate health hazards. They contribute to significant energy saving by preventing HVAC system blockages.

- Transportation Infrastructure: Bridges, railway stations, airports, and roadside signage require effective bird control to prevent structural damage, electrical faults (e.g., from nesting materials), and visual obstructions, ensuring public safety and operational efficiency.

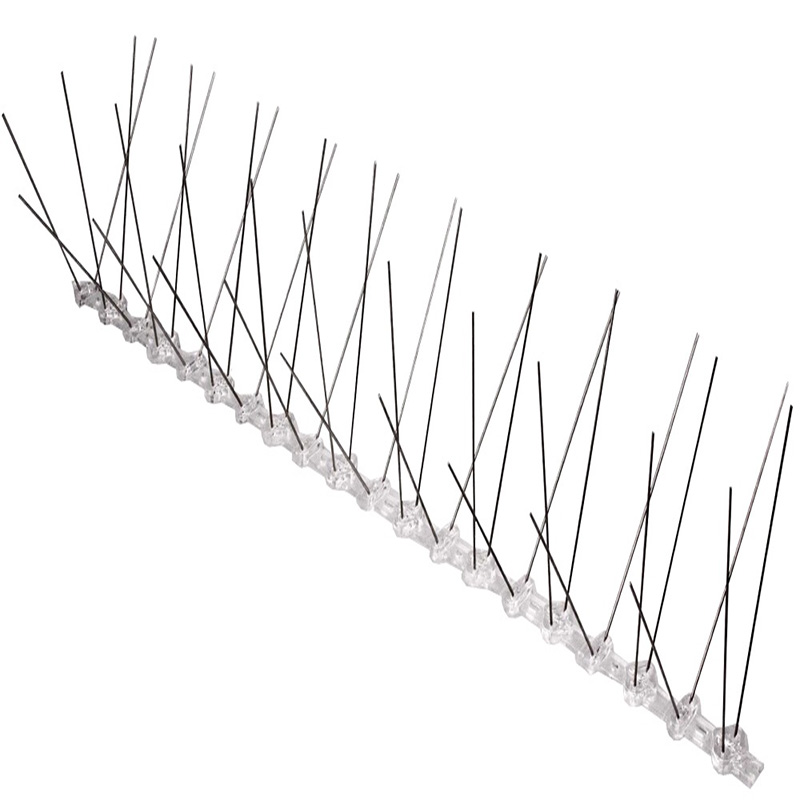

Image 1: Precision-engineered anti-bird spikes ready for deployment, showcasing the quality offered by a leading anti bird spikes exporter.

Current Industry Trends and Market Dynamics

The global market for bird control solutions, heavily influenced by leading anti bird spikes exporters, is experiencing steady growth driven by increasing urbanization, heightened awareness of public health, and stringent environmental and maintenance regulations. Key trends shaping the industry include:

- Sustainable Materials: A growing demand for bird spikes made from recycled or more environmentally friendly materials, without compromising on durability or effectiveness.

- Aesthetic Integration: An increased focus on solutions that blend seamlessly with architectural designs, offering discreet yet highly effective bird deterrents, crucial for modern commercial and historic buildings.

- Modular and Customizable Systems: Leading anti bird spikes factories are investing in the production of modular designs that can be easily installed on various complex surfaces and adapted to specific architectural challenges or bird species.

- Enhanced Durability & Longevity: A shift towards products offering extended warranties and proven longer service lives, reflecting a desire for lower lifecycle costs and reduced replacement frequency.

- Increased Demand from Emerging Economies: Rapid infrastructure development and rising commercial property investments in regions such as Asia, Africa, and Latin America are fueling a significant demand for effective and durable bird control solutions from reliable anti bird spikes suppliers.

According to industry reports, the global bird control market size was valued at USD 1.2 billion in 2022 and is projected to reach USD 1.8 billion by 2030, exhibiting a Compound Annual Growth Rate (CAGR) of 5.3% from 2023 to 2030 (Source: Grand View Research, 2023). This robust growth underscores the critical role of sophisticated manufacturing and efficient supply chains provided by experienced anti bird spikes manufacturers.

Technical Specifications and Product Parameters

Understanding the precise technical parameters is vital for B2B clients to specify the correct bird spike solution for their projects. A leading anti bird spikes exporter offers a range of configurations engineered to suit diverse applications and bird species.

Typical Bird Spike Specifications

| Parameter | Stainless Steel Spikes (Type 304/316) | Polycarbonate Spikes | Hybrid Spikes (SS on PC Base) |

|---|---|---|---|

| Material Composition | SUS304/SUS316 Grade Stainless Steel | UV-Stabilized Virgin Polycarbonate | SUS304/SUS316 Spikes on UV-Stabilized PC Base |

| Spike Height | 110mm - 160mm (4.3 - 6.3 inches) | 100mm - 150mm (3.9 - 5.9 inches) | 110mm - 160mm (4.3 - 6.3 inches) |

| Base Width | 20mm - 30mm (0.8 - 1.2 inches) | 25mm - 40mm (1.0 - 1.6 inches) | 25mm - 40mm (1.0 - 1.6 inches) |

| Coverage Width | 120mm - 200mm (4.7 - 7.9 inches) | 100mm - 250mm (3.9 - 9.8 inches) | 120mm - 250mm (4.7 - 9.8 inches) |

| Spike Diameter | 1.3mm - 1.6mm (at base) | 1.5mm - 2.0mm (at base) | 1.3mm - 1.6mm (at base) |

| Section Length | 25cm, 33cm, 50cm, 100cm (customizable) | 33cm, 50cm, 100cm (customizable) | 33cm, 50cm, 100cm (customizable) |

| Number of Spikes/50cm | 40-80 (depending on row configuration) | 30-60 (depending on row configuration) | 40-80 (depending on row configuration) |

| Attachment Method | Screws, Outdoor Adhesive, Cable Ties | Screws, Outdoor Adhesive, Cable Ties | Screws, Outdoor Adhesive, Cable Ties |

| Durability (Expected Lifespan) | 15-25 Years+ | 10-15 Years | 15-20 Years |

These parameters demonstrate the flexibility and robust engineering behind bird spike solutions, allowing for precise selection based on bird species, aesthetic considerations, and environmental factors.

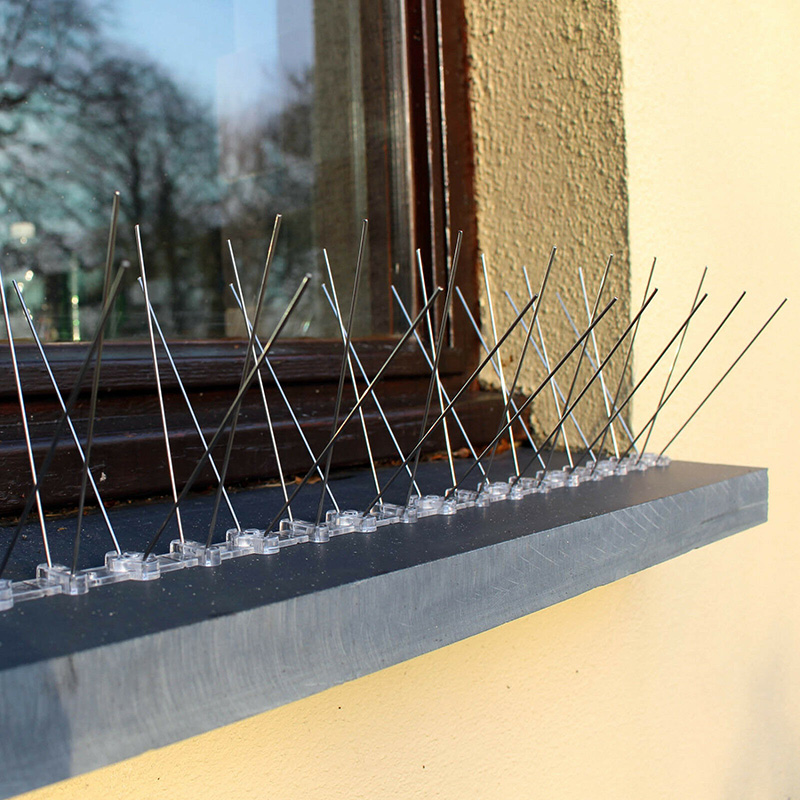

Image 2: A variety of anti-bird spike configurations for different architectural requirements, as supplied by a diverse anti bird spikes exporter.

Application Scenarios and Real-World Impact

The versatility of anti-bird spikes, offered by reliable anti bird spikes suppliers, makes them suitable for a vast array of application scenarios, delivering tangible benefits across various sectors by mitigating the costly and damaging effects of bird activity.

- Building Ledges and Parapets: Protecting architectural aesthetics and preventing corrosive droppings from defacing facades, which often leads to costly specialized cleaning, structural degradation, and health hazards from airborne pathogens.

- Signage and Billboards: Ensuring visibility and integrity of advertisements and informational signs by deterring nesting birds that can obscure messages, damage electrical components, or destabilize structures.

- CCTV Cameras and Lighting Fixtures: Preventing birds from perching on and fouling sensitive security and illumination equipment, thereby ensuring uninterrupted surveillance, optimal lighting performance, and reducing maintenance cycles. A common application for solutions from proficient bird spikes suppliers.

- Solar Panels: Maintaining the optimal efficiency of photovoltaic systems by preventing birds from nesting underneath or perching on panels, which can lead to shading, scratching, and debris accumulation that significantly diminishes energy output.

- Rooflines and Gutters: Preventing blockages and structural damage caused by nesting materials and droppings in gutters and drainage systems, thereby averting water ingress into buildings and maintaining proper water flow.

- Industrial Machinery and Pipework: Protecting exposed machinery, ventilation systems, and complex pipe networks in factories, warehouses, and outdoor industrial sites from bird droppings that can corrode sensitive parts, cause electrical shorts, or create operational hazards.

Customer Feedback and Service Case Details

A prominent multinational logistics hub, managing high-volume freight traffic, faced persistent issues with pigeons nesting in their expansive loading bay awnings and structural beams. This resulted in unsanitary conditions, potential health risks for personnel, and accelerated corrosion of metal structures due to acidic droppings. After a comprehensive site assessment and consultation with a leading anti bird spikes exporter, a bespoke solution involving multi-row stainless steel spikes on galvanized steel bases was installed along all critical ledges and beams. The client reported a remarkable 95% reduction in bird activity within the first month of installation. This led to significantly improved hygiene standards, a noticeable decrease in cleaning costs, and a safer working environment. The facility manager commented, "The durability and effectiveness of the spikes far exceeded our expectations. This has provided a long-term, low-maintenance solution that directly contributes to our operational efficiency and employee well-being." This demonstrates the practical, quantifiable benefits derived from strategically deployed bird control measures.

Technical Advantages of Premium Anti-Bird Spikes

The selection of high-quality bird spikes from a reputable anti bird spikes exporter offers several distinct technical advantages critical for long-term effectiveness, minimal total cost of ownership, and a superior return on investment for B2B clients.

- Superior Material Durability: As detailed in the material specifications, the use of SUS304/SUS316 stainless steel guarantees exceptional resistance to rust, corrosion, and UV degradation, making them ideal for even the most aggressive coastal or industrial environments. UV-stabilized polycarbonate ensures that plastic components do not become brittle, crack, or discolor over time, maintaining their structural integrity and aesthetic appeal.

- Engineered Effectiveness: The precise spacing, height, and angle of spikes are scientifically determined and field-tested to effectively prevent birds from landing or perching without causing them any harm. Spike densities are meticulously optimized to ensure there are no gaps large enough for even smaller bird species to exploit.

- Versatile and Secure Installation: Flexible and robust bases, often equipped with pre-drilled holes or integrated adhesive channels, allow for secure attachment to a wide variety of surfaces including concrete, steel, wood, PVC, and glass. This adaptability accommodates complex architectural features and diverse building materials. This flexibility is a hallmark of products from skilled anti bird spikes factories.

- Low Maintenance Requirement: Once installed correctly, premium bird spikes are designed to be a set-and-forget solution, requiring minimal to no ongoing maintenance. This significantly reduces long-term operational costs associated with recurring bird pest control measures or property damage repairs.

- Humane Deterrent: The carefully engineered design ensures that birds are simply deterred from landing and perching, not injured. This aligns with ethical pest control practices and increasingly stringent wildlife protection regulations, promoting a responsible approach to bird management.

- Aesthetic Discretion: Available in various materials and colors (e.g., clear polycarbonate, natural silver stainless steel, or custom powder-coated options) to blend discreetly with different building materials and architectural styles, maintaining the aesthetic integrity of the structure.

Image 3: Demonstrating the discreet yet effective application of anti-bird spikes on a modern commercial building, a testament to the versatility of a good anti bird spikes exporter.

Vendor Comparison: Selecting the Right Anti-Bird Spikes Exporter

Choosing the optimal anti bird spikes exporter requires a meticulous evaluation of several key criteria that extend beyond just initial product specifications. B2B decision-makers must consider a vendor's holistic offering, including manufacturing quality, certifications, support, and customization capabilities to ensure a successful long-term partnership.

Key Comparison Parameters for Anti-Bird Spike Suppliers

| Criterion | Premium Exporter (e.g., GalvanizedMeshProducts) | Standard Exporter | Budget Exporter |

|---|---|---|---|

| Material Quality & Traceability | Certified SUS304/316, UV-Stabilized Virgin PC, Full Material Traceability | Basic SUS201, Non-UV Stabilized PC, Limited Traceability | Potentially Recycled Metals, Non-Virgin PC, No Traceability |

| Manufacturing Process & Precision | Precision CNC, Advanced Injection Molding, Robust Bonding, Automated QC | Standard Punching/Bending, Basic Molding, Manual QC | Manual Assembly, Low-Quality Molding, Minimal QC |

| Certifications & Compliance | ISO 9001:2015, CE, ASTM, REACH, RoHS Compliance, Test Reports | Basic QC, Local Standards, Limited Documentation | Minimal or No Certifications, Self-Declared Compliance |

| Product Warranty & Guarantees | 5-10 Years on Materials & Workmanship (documented) | 1-2 Years Limited Warranty (often with caveats) | No or Very Limited Warranty, Difficult Claim Process |

| Customization & Engineering Support | Extensive (material, color, spike density, length, CAD/BIM support) | Limited (standard lengths/colors), Minimal Technical Support | Virtually None, No Engineering Assistance |

| Lead Time & Global Logistics | Reliable, On-time Delivery, Global Shipping Expertise, Customs Support | Variable, Standard Shipping Only, Limited Logistics Support | Unpredictable, Minimal Logistics Support, Potential Delays |

| After-Sales Support & Technical Assistance | Dedicated Support Team, Installation Guidance, On-site Consultation (as needed) | Basic Email Support, Limited Troubleshooting | Virtually Non-existent, No Technical Guidance |

This comparison highlights that investing in a premium anti bird spikes exporter ensures not only product quality but also comprehensive service, reliability, and long-term value, mitigating risks associated with inferior products.

Customized Solutions from Leading Anti-Bird Spikes Manufacturers

Recognizing that not all architectural or industrial challenges are standard, a top-tier anti bird spikes manufacturer excels in providing tailored solutions. This capability is crucial for complex projects where off-the-shelf products may not be sufficient to provide optimal protection or seamless integration.

- Bespoke Dimensions: Manufacturing spikes with specific heights, widths, or base lengths to perfectly fit irregular ledges, intricate pipework, unusually narrow window sills, or exceptionally wide parapets. This ensures comprehensive coverage and prevents birds from finding unprotected spaces.

- Material Customization: Offering specialized alloys (e.g., higher grades of stainless steel for extreme chemical resistance in industrial zones) or custom-colored polycarbonate to precisely match specific brand guidelines, building facades, or local aesthetic regulations, ensuring minimal visual impact.

- Varied Spike Density & Configuration: Adjusting the number of spike rows, the density of individual spikes, or their angles to effectively deter different bird species (e.g., smaller birds require denser, finer spikes) or to accommodate varying levels of bird pressure in specific areas.

- Integrated Mounting Systems: Developing custom mounting brackets, clips, or pre-assembled sections to facilitate easier, faster, and more secure installation on challenging substrates or complex structures such as solar panel arrays, communication towers, or historical monuments.

- Branding & Packaging: Providing options for private labeling and custom packaging, which is crucial for large distributors, national retailers, and major installation companies seeking to maintain their brand identity and streamline logistics.

This ability to engineer specific solutions demonstrates a manufacturer's commitment to solving unique client challenges, providing optimal effectiveness and aesthetic integration for every project.

Application Case Studies: Proven Success in Bird Control

Real-world applications unequivocally highlight the efficacy and strategic value provided by a proficient anti bird spikes exporter, demonstrating their impact on protecting assets and maintaining operational integrity.

Case Study 1: Airport Hangar Protection

A major international airport in a coastal region faced severe and persistent issues with large bird species, primarily gulls and pigeons, nesting in the expansive rafters, ledges, and external light fixtures of its aircraft maintenance hangars. Bird droppings posed a significant risk to expensive aircraft components, created unsanitary conditions for ground staff, and contributed to foreign object debris (FOD) hazards. A specialized anti bird spikes exporter was engaged to design and supply a robust bird control system. Over 5,000 linear meters of heavy-duty stainless steel bird spikes (Type 316 for enhanced corrosion resistance due to the saline environment) were installed on all susceptible surfaces. The installation, meticulously planned and completed over three weeks during scheduled maintenance windows, resulted in an immediate and significant reduction (over 98%) in bird presence within and around the hangars. This directly improved hangar cleanliness, drastically reduced FOD risks, and minimized costly aircraft cleaning requirements. The airport operations manager highly commended the solution for its long-term effectiveness, minimal visual impact, and contribution to operational safety and efficiency.

Case Study 2: Historic Building Preservation

A centuries-old university building, recognized as a national heritage site, required a discreet yet highly effective solution to deter pigeons and starlings from damaging its intricate stone carvings, ornate cornices, and vulnerable rooflines. Standard, visually intrusive bird control methods were deemed unacceptable due to strict preservation guidelines. A specialist anti bird spikes exporter collaborated closely with the university's preservation architects. They supplied clear, UV-stabilized polycarbonate spikes, specifically designed for minimal visibility, which were precisely installed with advanced architectural adhesive on sensitive stone surfaces. Where necessary, custom-sized spike sections were fabricated to fit unique architectural contours. The intervention successfully protected the building's historical integrity from avian damage, preserving its irreplaceable facade without compromising its aesthetic value, thereby satisfying all stringent preservation committees and maintaining the building's prestige.

Image 4: Successful application of bird spikes on an industrial facility, showcasing effective, long-term bird control solutions provided by a reliable anti bird spikes exporter.

Trust and Reliability: FAQ, Lead Time, Warranty, and Support

A trustworthy anti bird spikes exporter prioritizes transparent communication and robust customer support, building long-term partnerships with B2B clients based on reliability, accountability, and technical expertise.

Frequently Asked Questions (FAQ)

- Q: Are your bird spikes humane and compliant with wildlife regulations?

- A: Yes, our bird spikes are rigorously designed as a passive physical deterrent. They prevent birds from landing and perching without causing them any harm or injury, thereby fully complying with international and local wildlife protection regulations.

- Q: What is the expected lifespan of your bird spike products?

- A: Our premium stainless steel spikes typically offer an exceptional service life of 15-25 years, while our UV-stabilized polycarbonate spikes provide robust protection for 10-15 years, depending on specific environmental exposure and installation quality.

- Q: How are your bird spikes typically installed, and do you provide guidance?

- A: Installation is designed to be straightforward. Common methods include using outdoor-grade construction adhesive, screws, or cable ties, depending on the surface material and specific application. We provide comprehensive, detailed installation guides and can offer expert technical consultation for complex projects.

- Q: Can your spikes be customized for unique or large-scale projects?

- A: Absolutely. We pride ourselves on offering extensive customization options, including specific materials, dimensions (height, width, length), spike density, color-matching, and integrated mounting solutions to precisely meet the unique requirements of any project, regardless of scale or complexity.

Lead Time and Fulfillment Details

For standard orders of our Bird Spike product (available at https://www.galvanizedmeshproducts.com/bird-spike.html), we maintain an efficient production cycle, typically resulting in a lead time of 7-14 business days, depending on current order volume and specific product configurations. For large-scale projects, custom-designed solutions, or specialized material requirements, lead times will be precisely confirmed upon detailed order placement. We leverage a robust and reliable global logistics network to ensure timely and efficient delivery to our international clients, often collaborating with established freight forwarders to optimize shipping costs, customs clearance, and transit times for seamless door-to-door service.

Warranty Commitments

We stand unequivocally by the superior quality and craftsmanship of our products. All bird spikes exported by us are backed by a comprehensive warranty: a 5-year warranty on materials and workmanship for our advanced polycarbonate variants and an industry-leading 10-year warranty for our stainless steel products. These warranties are effective from the date of purchase and cover manufacturing defects and material failures under normal use conditions. Our commitment to quality is reinforced by strict ISO 9001 certified manufacturing processes. Full warranty terms and conditions, including detailed coverage and claim procedures, are readily available upon request.

Customer Support Information

Our dedicated and highly knowledgeable customer support team is available to assist B2B clients at every stage of their project – from initial product selection and technical inquiries to installation guidance and comprehensive after-sales service. We offer multi-channel support via email, direct phone lines, and online consultation platforms, ensuring that our clients receive prompt, expert, and tailored assistance throughout their project lifecycle. Our unwavering commitment is to ensure complete client satisfaction and the long-term, optimal performance of our bird control solutions, fostering lasting partnerships.

Conclusion: Partnering with a Proven Anti-Bird Spikes Exporter

The selection of an appropriate and effective bird control solution represents a strategic, long-term investment for any organization. By choosing a reputable anti bird spikes exporter with a proven track record in manufacturing excellence, unwavering adherence to international quality standards, and a strong, demonstrated commitment to comprehensive customer satisfaction, businesses can ensure the enduring protection of their valuable assets and critical infrastructure. From meticulously detailed technical specifications and robust product warranties to flexible customized solutions and dedicated after-sales support, the right partner provides not just a product, but a complete, reliable, and highly effective bird management strategy that delivers tangible benefits and peace of mind.

References

- Grand View Research. (2023). Bird Control Market Size, Share & Trends Analysis Report By Product (Netting, Spikes, Audio & Visual Repellents), By Application (Commercial, Residential, Industrial), By Region, And Segment Forecasts, 2023 - 2030. Available at: https://www.grandviewresearch.com/industry-analysis/bird-control-market

- ASTM International. (2023). ASTM G154: Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. Available at: https://www.astm.org/g0154-23.html

- International Organization for Standardization. (2023). ISO 9227: Corrosion tests in artificial atmospheres -- Salt spray tests. Available at: https://www.iso.org/standard/74028.html

- ISO 9001: Quality management systems -- Requirements. (2023). Available at: https://www.iso.org/iso-9001-quality-management.html

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025