-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 13, 2025 08:20 Back to list

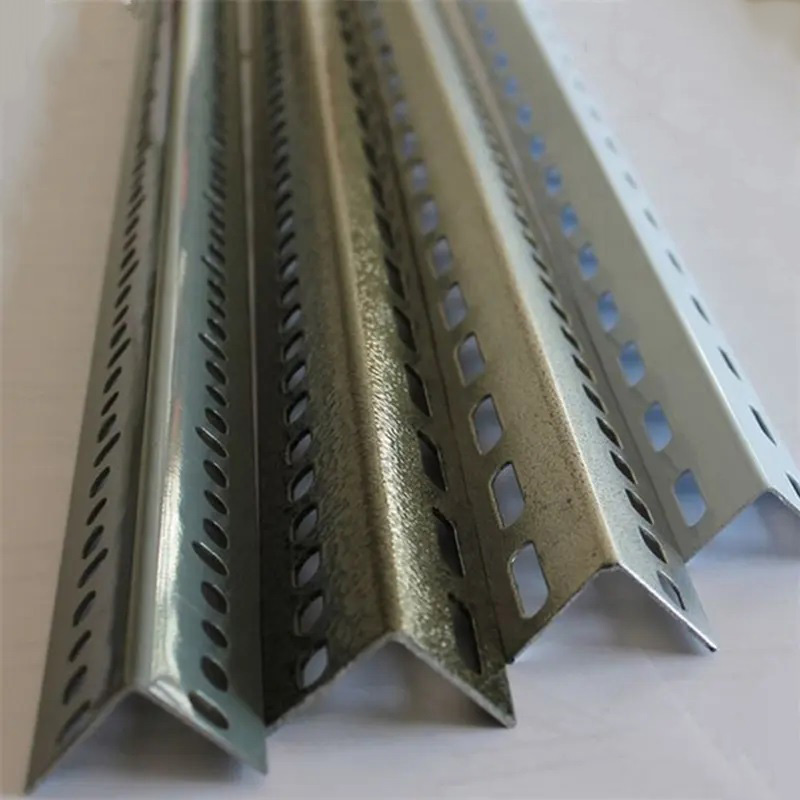

Stainless Steel Angle Factories: Premium Quality & Custom Solutions

Introduction to Precision Stainless Steel Angles

Stainless steel angles, or angle bars, are fundamental structural components widely utilized across various industrial sectors for their exceptional strength, corrosion resistance, and aesthetic appeal. These versatile profiles are crucial in applications ranging from architectural framing and structural support to complex machinery fabrication and chemical processing plants. The demand for high-quality, precisely manufactured stainless steel angles continues to grow, driven by stringent industry requirements for durability and performance.

Choosing the right manufacturer is paramount, as the quality of the angle bar directly impacts the integrity and longevity of the end-use application. This article delves into the critical aspects of selecting reputable stainless steel angle factories, exploring their manufacturing processes, technical specifications, application advantages, and crucial factors for vendor comparison. Our aim is to provide B2B decision-makers and engineers with comprehensive insights to ensure optimal procurement and project success.

The Advanced Manufacturing Process of Stainless Steel Angle Bars

The production of stainless steel angles involves a sophisticated series of steps designed to ensure material integrity, precise dimensions, and superior surface finish. Reputable stainless steel angle factories adhere to stringent quality control measures throughout the entire process.

1. Raw Material Sourcing and Preparation

- Material Selection: High-grade stainless steel billets, typically AISI 304, 316, 316L, 201, or 430, are selected based on desired corrosion resistance, strength, and weldability. Specifications such as ASTM A276 or EN 10088 define the chemical composition and mechanical properties.

- Inspection: Incoming raw materials undergo rigorous spectral analysis and visual inspection to confirm alloy composition and absence of defects.

2. Heating and Rolling

- Pre-heating: Billets are heated in controlled furnaces to temperatures typically ranging from 1000°C to 1250°C, ensuring uniform plasticity for subsequent deformation.

- Hot Rolling: The heated billets pass through a series of rolling stands, where they are progressively shaped into the desired angle profile. This process, often referred to as hot-rolled or hot-finished, improves grain structure and mechanical properties. The precision of the rolling mills directly influences the final dimensional accuracy.

3. Cooling and Straightening

- Controlled Cooling: After rolling, the angle bars are cooled, often under controlled conditions to prevent warping and internal stresses.

- Straightening: Mechanical straighteners are employed to ensure the angles meet specific straightness tolerances, critical for structural applications.

4. Finishing and Post-Processing

- Cutting: The continuous profiles are cut to standard or customized lengths using precision shears or saws.

- Shot Blasting/Pickling: To remove scale and improve surface finish, angles may undergo shot blasting or acid pickling, a process that enhances corrosion resistance and prepares the surface for further treatments.

- Cold Drawing/Cold Forming (Optional): For specific applications requiring tighter tolerances, smoother surfaces, or enhanced mechanical properties, some steel slotted angles exporters may employ cold drawing or cold forming processes, which involve pulling or pressing the hot-rolled material through dies at room temperature.

- Hole Punching/Slotting (for Angle Hole Bars): For 'Angle Hole / Angle Bars', automated CNC punching or drilling machines create precise holes or slots according to design specifications, ensuring perfect alignment and minimizing material stress.

5. Quality Control and Testing

- Dimensional Inspection: Calipers and laser measurement systems verify length, leg dimensions, thickness, and angle accuracy against standards like ASTM A484, ANSI, and ISO 65.

- Mechanical Testing: Tensile strength, yield strength, elongation, and hardness tests (e.g., Brinell, Rockwell) are conducted to confirm material properties meet specified requirements.

- Corrosion Resistance Testing: Salt spray tests or intergranular corrosion tests may be performed for specific grades (e.g., ASTM A262 for intergranular corrosion).

- Surface Finish Inspection: Visual and instrumental methods assess surface quality, ensuring freedom from cracks, pitting, and other defects.

This rigorous process ensures that the final product from steel slotted angles factories meets the demanding performance and reliability standards expected by various industries.

Technical Specifications and Industry Standards

The technical specifications of stainless steel angles are critical for ensuring their suitability for intended applications. These parameters, defined by international and national standards, govern everything from material composition to dimensional tolerances and mechanical properties.

Key Material Grades and Their Properties

- AISI 304 (1.4301): The most common austenitic stainless steel, offering excellent corrosion resistance, good formability, and weldability. Ideal for general purpose applications, food processing, and architectural components.

- AISI 316/316L (1.4401/1.4404): Contains molybdenum, enhancing resistance to pitting and crevice corrosion in chloride environments. Essential for marine, chemical, pharmaceutical, and petrochemical industries. The 'L' grade indicates lower carbon content for improved weldability and reduced sensitization.

- AISI 201 (1.4372): An economical alternative with good formability but lower corrosion resistance compared to 304. Often used in non-critical indoor applications or where cost is a primary concern.

- AISI 430 (1.4016): A ferritic stainless steel with good corrosion resistance in mild environments and good heat resistance. Used in appliance trim, automotive parts, and catering equipment.

Typical Product Specification Table: Stainless Steel Angle Hole Bar (Hot Rolled)

Adherence to these specifications is a hallmark of reliable stainless steel angle suppliers, ensuring that products are fit for their intended purpose and compliant with regulatory frameworks.

Industry Trends and Market Dynamics

The market for stainless steel angles is influenced by global economic shifts, infrastructure development, and evolving material science. Current trends indicate a rising demand for high-performance and specialty stainless steel grades, particularly in sectors requiring enhanced durability and resistance to harsh environments.

- Sustainability Focus: Increasing emphasis on sustainable manufacturing practices, including energy efficiency in production and recyclability of stainless steel.

- Advanced Fabrication: Growth in demand for pre-fabricated and custom-slotted angles, reducing on-site labor and improving construction efficiency.

- Digitalization: Adoption of Industry 4.0 technologies such as IoT-enabled monitoring in steel slotted angles factory settings for optimized production, predictive maintenance, and enhanced quality control.

- Globalization of Supply Chains: B2B buyers increasingly seek steel slotted angles exporters capable of navigating complex international logistics and meeting diverse regional standards.

These trends highlight the importance for manufacturers to invest in R&D and advanced production capabilities to remain competitive and meet future market demands.

Application Scenarios and Technical Advantages

Stainless steel angles are indispensable across a multitude of industries due to their superior performance characteristics. Their inherent properties make them ideal for challenging environments and critical structural applications.

Target Industries:

- Petrochemical and Chemical Processing: Used for structural supports, platforms, and frameworks where exposure to corrosive chemicals necessitates high resistance. The extended service life in these aggressive conditions translates to significant cost savings in maintenance and replacement.

- Food and Beverage Industry: For sanitary equipment, structural frames, and processing lines due to their ease of cleaning, hygiene properties, and resistance to acids and sanitizers.

- Marine and Offshore: Critical for shipbuilding, docks, and offshore platforms, offering excellent resistance to saltwater corrosion and extreme weather.

- Construction and Architecture: Employed in façade systems, interior fittings, decorative elements, and general structural supports where aesthetics and long-term durability are key.

- Water Supply & Drainage Systems: For bracing and structural components in water treatment plants, pumping stations, and sewage infrastructure, providing reliable corrosion protection.

- Metallurgy and Heavy Industry: Supporting heavy machinery, conveying systems, and industrial infrastructure where strength and resistance to high temperatures or abrasive conditions are required.

Demonstrated Advantages:

- Corrosion Resistance: Stainless steel forms a passive chromium oxide layer that protects against rust and various corrosive agents, significantly extending the service life compared to carbon steel, particularly in harsh environments. This reduces the lifecycle cost of projects.

- High Strength-to-Weight Ratio: Offers robust structural integrity without excessive weight, allowing for efficient designs and reduced material usage in some applications.

- Durability and Longevity: Resistant to wear, impact, and fatigue, leading to minimal maintenance requirements and an extended operational lifespan, often exceeding 50 years in benign environments.

- Aesthetics: The inherent bright and clean appearance of stainless steel is often desired in architectural and visible industrial applications, eliminating the need for painting or protective coatings.

- Temperature Resistance: Maintains mechanical properties across a wide range of temperatures, from cryogenic to elevated heat, making it suitable for diverse operational conditions.

- Recyclability: Stainless steel is 100% recyclable, contributing to sustainable practices and reducing environmental impact.

These advantages underscore why discerning B2B buyers consistently turn to reputable steel slotted angles manufacturers for their critical projects.

Vendor Comparison and Selection Criteria for Stainless Steel Angles

Selecting the right stainless steel angle supplier is a strategic decision that impacts project timelines, budget, and long-term operational costs. A thorough vendor comparison goes beyond just price, focusing on reliability, quality, and service capabilities.

Key Factors for Evaluation:

- Quality Assurance and Certifications: Look for ISO 9001 certified manufacturers. Compliance with international standards (ASTM, EN, JIS) and product-specific certifications (e.g., CE marking for structural components) are non-negotiable.

- Manufacturing Capabilities: Assess production capacity, the range of grades and dimensions offered, and the ability to perform precise hole punching or slotting. Factories with advanced CNC machinery can provide superior precision for slotted angles.

- Material Traceability: A reputable steel slotted angles manufacturer provides full material traceability, from raw billet to finished product, via mill test certificates (MTCs).

- Customization and Engineering Support: Ability to offer bespoke solutions, including non-standard sizes, specialized finishes, or unique hole patterns, supported by experienced engineering teams.

- Lead Time and Logistics: Evaluate the supplier's efficiency in order fulfillment, packaging, and international shipping capabilities, crucial for global projects.

- Customer Service and After-Sales Support: Responsiveness, clear communication, and robust warranty commitments are indicators of a reliable partner.

- Reputation and Experience: Longevity in the market, positive customer feedback, and a strong portfolio of successful projects (especially from stainless steel angle factories with decades of experience) are significant trust factors.

Comparative Analysis: Generic Stainless Steel Angle Suppliers

Customized Solutions and Application Case Studies

The versatility of stainless steel angles is further enhanced by the ability of leading stainless steel angle manufacturers to offer tailored solutions. Customization allows for optimization in design, reduction of on-site fabrication, and precise integration into complex systems.

Customization Capabilities Include:

- Non-Standard Dimensions: Production of angles with specific leg lengths, thicknesses, or non-standard angles (e.g., unequal leg angles) to meet unique structural requirements.

- Precision Hole Punching/Slotting: Customized hole patterns, sizes, and spacing for seamless integration with existing structures or specific bolting requirements, minimizing drilling on-site.

- Specialized Finishes: Beyond standard mill finishes, options like polished (e.g., #4, #8 mirror), brushed, or electropolished surfaces for enhanced aesthetics, hygiene, or even greater corrosion resistance.

- Cut-to-Length Services: Pre-cutting angles to exact specified lengths, reducing material waste and on-site cutting time.

- Value-Added Services: Bending, welding, notching, or specialized packaging for ease of installation or transport.

Application Case Studies:

Case Study 1: Marine Grade Stainless Steel Angles for Offshore Platform Structure

A leading oil & gas company required a robust, corrosion-resistant framing system for a new offshore platform in the North Sea. They partnered with a specialized stainless steel angle supplier for custom-fabricated AISI 316L unequal leg angles. These angles were precisely cut-to-length and pre-drilled with specific bolt patterns to ensure rapid assembly on-site. The inherent resistance of 316L to chloride stress corrosion cracking, coupled with the manufacturer's precise fabrication, led to a 20% reduction in installation time and significantly extended the estimated service life of the platform's non-load-bearing superstructure.

Case Study 2: Hygienic Slotted Angles for Pharmaceutical Cleanroom

A pharmaceutical manufacturing plant needed a framework for new sterile processing equipment within a cleanroom environment. The primary concern was hygiene and ease of sanitization. A steel slotted angles manufacturer provided AISI 304 angles with a #4 brushed finish and custom-slotted patterns. The smooth, non-porous finish facilitated thorough cleaning and prevented microbial growth, while the pre-slotted design allowed for flexible adjustments of equipment without compromising structural integrity or cleanroom standards. The project was completed within budget and strict regulatory guidelines.

Trustworthiness and Customer Support ( Elements)

Establishing trust is paramount in B2B transactions. Reputable stainless steel angle factories demonstrate trustworthiness through transparent operations, clear commitments, and comprehensive customer support.

Frequently Asked Questions (FAQ)

Q: What are the primary differences between AISI 304 and 316L stainless steel angles?

A: AISI 304 is a general-purpose grade with excellent corrosion resistance and formability. AISI 316L contains molybdenum, significantly enhancing its resistance to pitting and crevice corrosion, especially in chloride-rich environments like marine or chemical processing applications. The 'L' denotes low carbon content for improved weldability.

Q: Can your steel slotted angles manufacturer provide custom hole patterns?

A: Yes, we offer extensive customization for hole patterns and slotting. Clients can provide CAD drawings or detailed specifications, and our engineering team will ensure precise manufacturing to meet project requirements.

Q: What testing standards do your products comply with?

A: Our stainless steel angles comply with international standards such as ASTM A276/A484 for material and dimensional specifications, EN 10088 for stainless steel grades, and ISO 9001 for quality management systems. Mill Test Certificates (MTCs) are provided with every order.

Lead Time and Fulfillment

Our standard lead time for common stainless steel angle grades and dimensions is typically 2-4 weeks. For custom orders or large volumes, lead times may vary but are always communicated clearly at the quotation stage. We maintain robust inventory levels of raw materials and leverage efficient production schedules to ensure timely delivery. Expedited options are available for urgent projects.

Warranty Commitments

All products from our steel slotted angles supplier are backed by a comprehensive warranty against manufacturing defects and material non-conformance. Our commitment ensures that products meet agreed-upon specifications and perform as expected under normal operating conditions. Detailed warranty terms are provided with every quotation and sales contract, reflecting our confidence in the quality and durability of our stainless steel angles.

Customer Support Information

Our dedicated customer support team is available to assist with technical inquiries, order tracking, and after-sales service. We pride ourselves on responsive communication and proactive problem-solving. Reach out via email, phone, or our online portal for expert assistance and project consultation. We are committed to fostering long-term partnerships built on trust and mutual success.

Conclusion

The selection of stainless steel angles is a critical decision for any B2B project demanding structural integrity, corrosion resistance, and long-term reliability. By understanding the intricate manufacturing processes, adhering to rigorous technical specifications, and partnering with reputable stainless steel angle factories, businesses can ensure the success and longevity of their investments. The emphasis on quality, customization, and comprehensive support services from experienced manufacturers distinguishes reliable suppliers in a competitive global market.

The information provided aims to empower industry professionals with the knowledge necessary to make informed procurement decisions, fostering innovation and operational excellence across various demanding sectors. Investing in high-quality stainless steel angles from an authoritative source ultimately translates into enhanced project performance and reduced lifecycle costs.

Citations

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization.

- ASTM A276 / A276M - 17, Standard Specification for Stainless Steel Bars and Shapes. ASTM International.

- EN 10088-2:2014, Stainless steels - Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes. European Committee for Standardization.

- The A-Z of Stainless Steel. AZoM.com. Available at: https://www.azom.com/materials.aspx?ArticleID=1029

- Stainless Steel in Architecture. World Stainless Steel Association (World Steel Association). Available at: https://www.worldstainless.org/

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025

-

Barbed Wire Fence: Durable Security Solutions for Global Agriculture and Industry

NewsNov.19,2025

-

Barbed Wire: Durable & Affordable Security Solutions for Global Applications

NewsNov.18,2025

-

Durable and Cost-Effective Fence Wire Mesh for Farm Sheep – Global Insights & Innovations

NewsNov.18,2025

-

Durable and Cost-Effective Farm Fencing Wire Galvanized | Global Use & Benefits

NewsNov.15,2025

-

Essential Guide to Wire for Fencing: Applications & Innovations

NewsNov.14,2025