-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 17, 2024 19:10 Back to list

Bird Cage Wire Mesh Manufacturers and Suppliers for Quality Craftsmanship

The Importance of Bird Cage Wire Mesh Factories

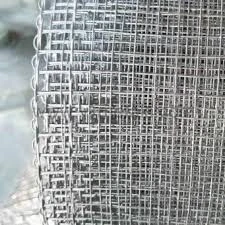

Bird cage wire mesh is an essential component in the manufacturing of bird cages. It provides the necessary durability and safety for birds while allowing for proper ventilation and visibility. With an increasing number of pet owners seeking to provide the best homes for their feathered friends, the role of bird cage wire mesh factories has never been more significant.

Bird cage wire mesh is manufactured using high-quality materials designed to withstand the conditions of both indoor and outdoor environments. These factories employ skilled workers who design and produce wire mesh that meets the specific requirements of bird cages. The process typically begins with the selection of raw materials. Stainless steel, galvanized wire, and PVC-coated wire are among the most popular choices for their strength and longevity.

Once the materials are sourced, they undergo a meticulous manufacturing process that involves weaving or welding the wire into appropriate mesh sizes. The openings in the mesh must be carefully calculated to prevent birds from escaping while ensuring they can still see and interact with their surroundings. Depending on the species of birds, different mesh sizes and wire thicknesses may be required. For example, finches may require a finer mesh, while larger birds like parrots need sturdier wire to prevent them from breaking free.

In addition to functionality, aesthetics play a crucial role in the production of bird cage wire mesh

. Many bird cage wire mesh factories offer customized options that cater to the preferences of pet owners. This includes various colors and finishes that can complement the decor of a home while providing a safe environment for birds.bird cage wire mesh factories

Safety is paramount in the production of bird cage wire mesh. Factories adhere to strict guidelines and quality control measures to ensure that the finished product is free from sharp edges and toxic materials. Additionally, many manufacturers are beginning to recognize the importance of using eco-friendly materials and processes to reduce their environmental impact. This shift not only appeals to the environmentally conscious consumer but also helps promote sustainable practices within the industry.

As the demand for pet birds continues to grow, bird cage wire mesh factories have become increasingly competitive. Innovative designs, superior quality, and affordability are all key factors that play a role in attracting customers. Many factories are now investing in advanced technology and machinery to improve production efficiency and reduce costs. Automation has allowed for faster production times without compromising quality.

Furthermore, the expansion of e-commerce has reshaped how bird cage wire mesh is marketed and distributed. Consumers can easily access a wider range of products online, and many factories now offer direct-to-consumer sales. This has opened up new opportunities for smaller manufacturers who can leverage the internet to compete with larger companies.

In conclusion, bird cage wire mesh factories play a vital role in ensuring the safety, comfort, and well-being of pet birds around the world. As pet ownership continues to rise, these factories must adapt to changing consumer demands while maintaining high standards of quality and safety. The future of bird cage wire mesh manufacturing looks promising, with opportunities for innovation and growth in a market that increasingly values pet care and welfare. By prioritizing quality, safety, and sustainability, bird cage wire mesh factories will continue to flourish and serve the needs of bird enthusiasts everywhere.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025