-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 05, 2024 01:17 Back to list

boundary wall wire fence factories

The Evolution of Boundary Wall Wire Fence Factories

In recent years, the demand for reliable boundary wall wire fences has surged, driven by rising concerns for security and property delineation. This has given rise to a proliferation of boundary wall wire fence factories, which are essential in producing robust fencing solutions that cater to various needs. This article delves into the significance of these factories, the production processes involved, the materials used, and the broader implications for industries and consumers.

The Importance of Boundary Wall Wire Fences

Boundary wall wire fences are integral to property security and aesthetics. They serve multiple purposes, including safeguarding agricultural lands, residential properties, commercial establishments, and industrial sites. Such fences not only define property lines but also act as deterrents against trespassing and theft. In urban areas, where privacy is often compromised, wire fences provide an essential layer of seclusion, while still maintaining visibility.

Production Processes in Wire Fence Factories

The operation of boundary wall wire fence factories involves several systematic processes. Initially, raw materials, primarily steel or galvanized wire, are sourced from reputable suppliers. The quality of these materials is crucial, as it directly impacts the durability and strength of the fencing produced.

Once the materials are obtained, the manufacturing process begins with wire drawing, which involves reducing the diameter of the wire to the desired thickness. This is followed by galvanization, a critical step that enhances corrosion resistance, thereby prolonging the life of the fence. After galvanization, the wire is shaped into various configurations, such as welded panels or chain-link setups, depending on the desired fence type.

Quality control is paramount throughout production

. Factories employ rigorous testing methods to ensure that every batch of wire meets industry standards. These measures not only ensure customer satisfaction but also fortify the factory's reputation in a competitive marketplace.Materials Used in Boundary Wall Wire Fences

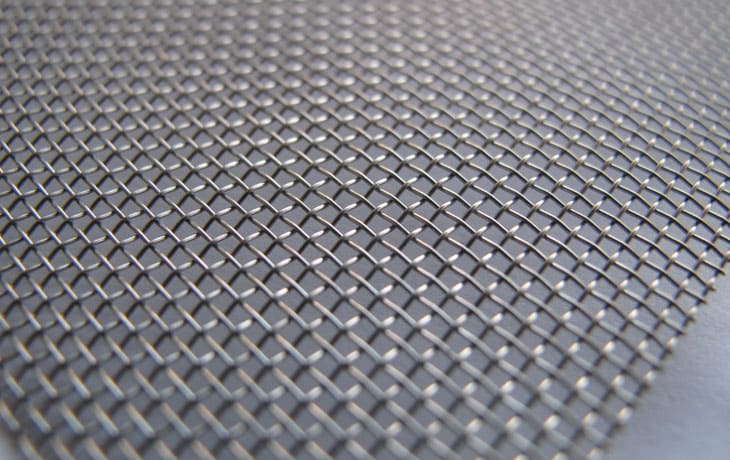

boundary wall wire fence factories

The choice of materials in the production of boundary wall wire fences can vary significantly. Galvanized steel is among the most popular due to its strength and resistance to rust. Stainless steel is another option, renowned for its durability and aesthetic appeal, making it suitable for both functional and decorative fencing.

Moreover, factories may also offer various coatings and finishes to enhance the appearance and longevity of the fences. Vinyl coatings, for example, provide additional weather resistance and come in a variety of colors to meet aesthetic preferences.

Economic and Environmental Considerations

The proliferation of boundary wall wire fence factories is not without its economic implications. These manufacturing hubs create jobs, supporting local economies while catering to a global market. Moreover, many factories are now implementing sustainable practices by recycling scrap metal and reducing waste during production, aligning with the growing global shift towards green manufacturing.

However, it is essential to remain vigilant about environmental impacts. Factories must prioritize eco-friendly materials and processes to minimize their carbon footprint and contribute positively to the community.

The Future of Boundary Wall Wire Fences

As urbanization continues and security concerns heighten, the future of boundary wall wire fences looks promising. Innovations in technology are poised to transform the industry, with advancements such as automated manufacturing processes and smart fencing solutions gaining traction. These innovations address consumer demands for higher security, ease of installation, and integration with home automation systems.

In conclusion, boundary wall wire fence factories play a crucial role in modern society by providing essential security solutions. From their production processes to the materials utilized, these factories are adapting to meet evolving needs. As they navigate economic and environmental challenges, their continued success will depend on innovation, quality, and sustainability. As consumers become more discerning, boundary wall wire fences will undoubtedly continue to evolve, solidifying their position as a staple in both residential and commercial landscapes.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025