-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 12, 2024 10:52 Back to list

chicken wire panels factory

The Rise of Chicken Wire Panels A Comprehensive Look at Their Production and Applications

In recent years, chicken wire panels have experienced a surge in popularity, becoming a staple in various industries including agriculture, construction, and home gardening. This versatile material, traditionally used for enclosures and fencing, is now recognized for its numerous practical applications. As the demand for chicken wire panels continues to grow, the factories producing them are modernizing their processes to meet market needs efficiently and sustainably.

Understanding Chicken Wire Panels

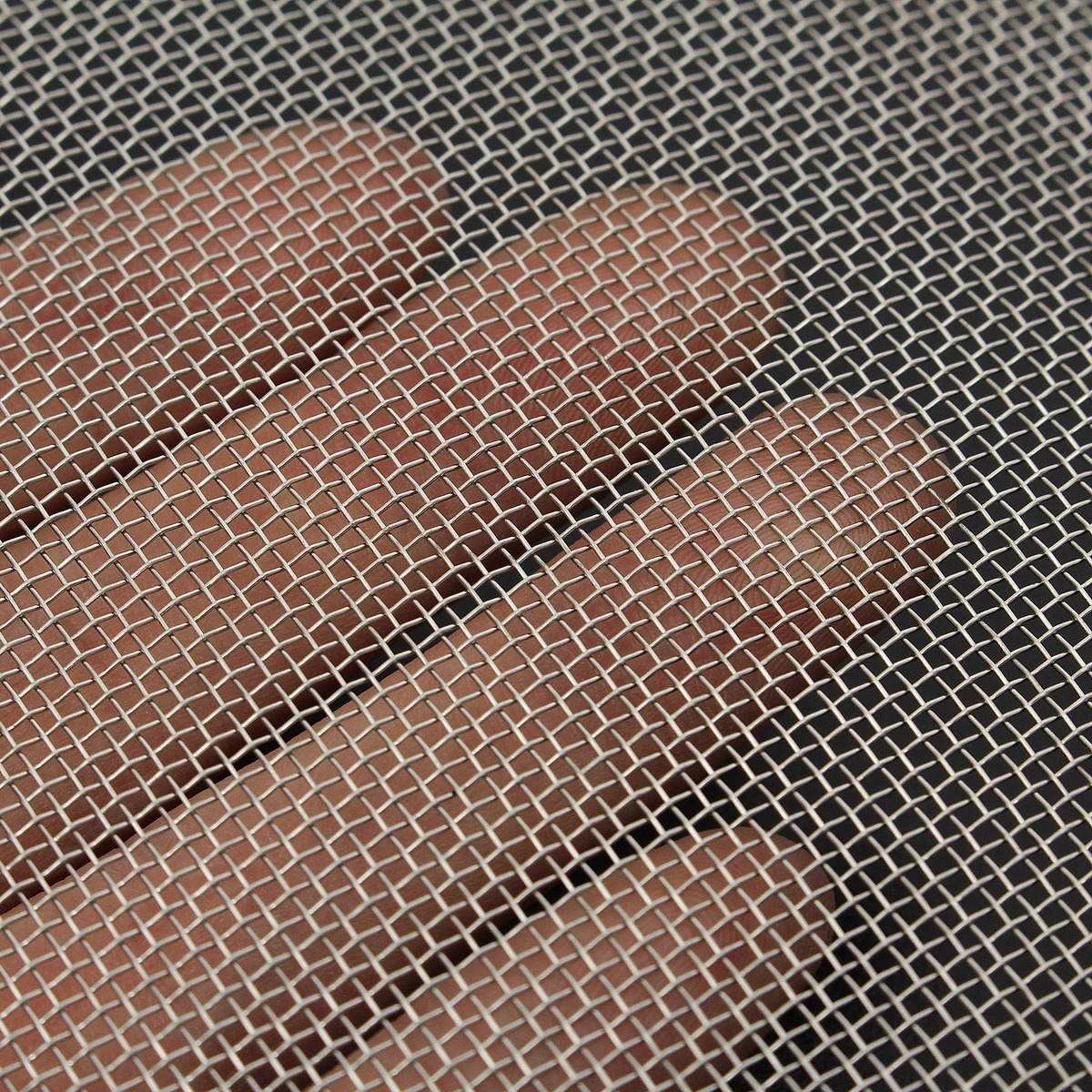

Chicken wire panels, also known as hex wire mesh or poultry netting, are made from thin, flexible wires twisted together to form a hexagonal pattern. Originally designed to contain poultry, these panels provide a lightweight yet robust barrier. Their durability and adaptability have led to widespread use beyond poultry farming. They are now utilized in various projects, including crafting decorative outdoor spaces, building trellises for climbing plants, and even as an effective solution for erosion control.

Production Process of Chicken Wire Panels

The production of chicken wire panels involves several stages, from raw material selection to the final packaging. Factories start with high-quality galvanized steel or stainless steel wire, known for their corrosion resistance and longevity. The process begins with wire drawing, where large coils of wire are drawn through a series of dies to achieve the desired thickness.

Once the wire is prepared, the next step is the formation of the hexagonal mesh. Modern factories utilize advanced machinery designed to efficiently twist and weave the wires into the iconic chicken wire pattern. This process ensures uniformity in size and spacing, which is crucial for applications where structural integrity is essential.

Post weaving, the panels undergo quality control checks to ensure they meet industry standards. Factors such as tensile strength, flexibility, and corrosion resistance are evaluated rigorously. After passing inspection, the panels are cut to size and packaged for distribution.

chicken wire panels factory

Sustainable Practices in Chicken Wire Production

In today's environmentally conscious market, many chicken wire panel factories are adopting sustainable practices. This includes using recycled materials in their wire production and investing in energy-efficient machinery. By minimizing waste and reducing their carbon footprint, these manufacturers not only contribute to environmental sustainability but also appeal to eco-aware consumers.

Furthermore, some factories are exploring advanced technologies such as automated production lines that enhance efficiency and reduce labor costs. With these advancements, they can produce high-quality chicken wire panels while maintaining competitive pricing in a fast-evolving market.

Versatile Applications of Chicken Wire Panels

The applications of chicken wire panels go far beyond their original purpose. In agriculture, they are widely used for fencing to protect livestock from predators and to create safe enclosures for small animals. In the construction industry, these panels serve as reinforcement for concrete and supporting structures due to their strength and flexibility.

Moreover, home gardeners appreciate the aesthetic appeal of chicken wire panels. They are often incorporated into garden designs as trellises or decorative screens, allowing plants to flourish while adding a rustic charm to outdoor spaces. In crafting, they are utilized in various DIY projects, from making custom decorations to creating unique furniture pieces.

Conclusion

As the market for chicken wire panels continues to expand, the factories producing them are evolving to meet consumer demands. By combining traditional manufacturing techniques with modern technology and sustainable practices, these factories play a crucial role in providing a product that is not only practical but also environmentally friendly. With their diversified applications and adaptability, chicken wire panels are poised to remain a vital resource across many sectors for the foreseeable future.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025