-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 16, 2024 10:00 Back to list

coarse wire mesh manufacturers

The Role of Coarse Wire Mesh Manufacturers in Various Industries

Coarse wire mesh is a fundamental material in many industrial and commercial applications, known for its strength, durability, and versatility. Manufacturers of coarse wire mesh play a vital role in providing essential products that cater to a wide range of industries, including construction, mining, agriculture, and filtration. This article delves into the significance of coarse wire mesh manufacturers, the types of products they offer, and their contributions to different sectors.

Understanding Coarse Wire Mesh

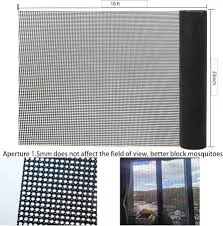

Coarse wire mesh is characterized by its large openings compared to finer mesh options, allowing for easier flow of air, liquids, and solids. Typically made from steel, stainless steel, or other durable materials, coarse wire mesh is designed to withstand harsh conditions and heavy usage. The manufacturing process involves weaving or welding together wires to create a sturdy grid that can be tailored to specific dimensions and requirements.

Key Products Offered by Manufacturers

Coarse wire mesh manufacturers offer a diverse range of products suitable for various applications

1. Screening and Sieving In the mining and construction sectors, coarse wire mesh is invaluable for sorting materials such as gravel, sand, and ore. Its robust construction ensures that it can handle the weight and abrasive nature of these materials.

2. Animal Husbandry In agriculture, coarse wire mesh is commonly used in enclosures, fencing, and feed storage. Its durability helps protect livestock from predators while allowing for proper ventilation.

coarse wire mesh manufacturers

3. Filtration Coarse wire mesh serves as a filter in various industries, including water treatment and chemical processing. It efficiently separates larger particles from fluids, ensuring a cleaner output.

4. Security Manufacturers produce coarse wire mesh for safety applications, such as cages and barriers. This mesh can be used in environments that require security without compromising visibility, benefiting areas like warehouses and airports.

Innovations and Customization

As technology advances, coarse wire mesh manufacturers are adopting new methods and techniques to enhance product quality and efficiency. Automation in the manufacturing process has led to increased precision and reduced production times, enabling manufacturers to meet growing demand.

Moreover, customization plays a significant role in the industry. Manufacturers can create bespoke mesh solutions tailored to specific customer needs, including variations in wire thickness, sizes of openings, and specific coatings for enhanced corrosion resistance.

The Future of Coarse Wire Mesh Manufacturing

The demand for coarse wire mesh is expected to continue growing, driven by the expansion of various industries and infrastructural development. Manufacturers are increasingly focusing on sustainable practices, such as using recycled materials and environmentally friendly processes.

In conclusion, coarse wire mesh manufacturers are integral to a multitude of industries, providing essential materials that contribute to safety, efficiency, and productivity. Their ability to adapt to market needs and innovate continuously positions them as key players in the industrial ecosystem. As industries evolve, the role of these manufacturers will undoubtedly become even more significant, paving the way for further advancements in mesh technology and application.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025