-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 04, 2024 01:25 Back to list

corrugated perforated metal factories

The Rise of Corrugated Perforated Metal Factories

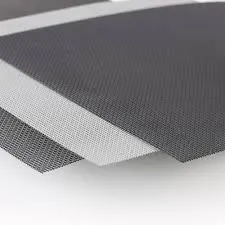

In recent years, corrugated perforated metal has emerged as a prominent material in various industries, thanks to its unique combination of strength, versatility, and aesthetic appeal. This trend has spurred the establishment of dedicated corrugated perforated metal factories around the globe, catering to the growing demand for this innovative material.

Corrugated perforated metal is characterized by its distinctive patterns, which involve a series of raised ridges and perforations. These features not only enhance the structural integrity of the metal but also allow for effective drainage, ventilation, and light transmission. This makes it ideal for applications in construction, architecture, automotive, and the manufacturing of decorative elements.

One of the primary advantages of corrugated perforated metal is its lightweight nature. Despite being robust, it is considerably lighter than traditional solid metal sheets. This property reduces transportation costs and eases installation processes. Furthermore, the perforations can be customized in size and pattern, allowing architects and designers to create unique and functional designs that meet the specific needs of their projects.

corrugated perforated metal factories

The rise of environmental consciousness has also played a significant role in the growth of corrugated perforated metal factories. Many manufacturers are shifting towards sustainable production methods that minimize waste and reduce carbon footprints. The recyclability of metal is a significant factor contributing to its popularity. Factories are increasingly adopting eco-friendly practices by using recycled metals as raw materials, thus promoting sustainability in the construction and manufacturing sectors.

The versatility of corrugated perforated metal opens doors to a wide range of applications. In architectural design, it is commonly used for facades, sunshades, and partition walls, providing both aesthetic and functional benefits. In industrial settings, it serves as an effective solution for filtration systems, sound barriers, and safety enclosures. Additionally, its applications range to art installations, where artists utilize its unique texture and form to create visually striking pieces.

As technology advances, so too do the capabilities of corrugated perforated metal factories. Modern manufacturing techniques, such as laser cutting and CNC machining, allow for precise production with minimal human intervention. This results in higher efficiency and consistency in product quality, which is critical in meeting the stringent demands of various industries.

In conclusion, the establishment of corrugated perforated metal factories marks an important development in the fields of manufacturing and design. With their ability to produce lightweight, durable, and aesthetically pleasing materials, these factories are well-positioned to meet the evolving needs of a diverse range of industries. As sustainability and innovation become increasingly important, corrugated perforated metal will likely play an even greater role in shaping the future of construction and design.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025