-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 29, 2024 17:01 Back to list

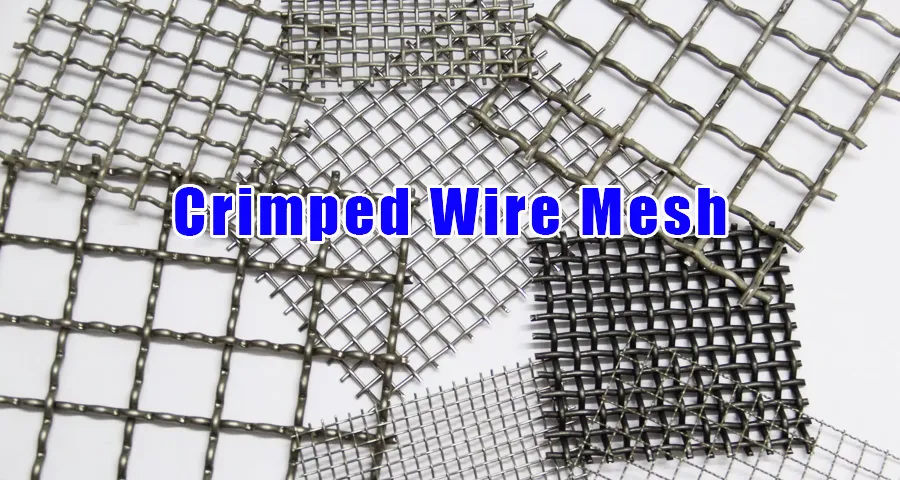

Durable Crimped Wire Mesh Solutions for Various Industrial Applications

The Versatility of Crimped Wire Mesh A Comprehensive Overview

Crimped wire mesh is a versatile material that finds applications across various industries, owing to its unique properties and structural integrity. The manufacturing process of crimped wire mesh involves weaving wires that have been mechanically crimped to create a robust, durable fabric. This article explores the characteristics, advantages, applications, and considerations of using crimped wire mesh in various settings.

Characteristics of Crimped Wire Mesh

Crimped wire mesh consists of wires that are pre-crimped before being woven together. This process creates a three-dimensional structure that enhances the mesh's strength and stability. Crimping adds rigidity and minimizes the movement of the wires, making the mesh less susceptible to deformation from stress or tensile forces. Typically made from materials such as stainless steel, carbon steel, aluminum, brass, and bronze, crimped wire mesh can be tailored to suit specific requirements regarding corrosion resistance, electrical conductivity, and weight.

The mesh can be produced in various wire diameters and crimp types, allowing for customizable spacing and patterns. Common configurations include the standard crimp, double crimp, and flat-top crimp, each affecting the overall performance and aesthetic of the final product.

Advantages of Crimped Wire Mesh

One of the primary advantages of crimped wire mesh is its strength-to-weight ratio. The crimping process enhances the tensile strength of the mesh while keeping it lightweight, making it easy to handle and install. Its durability ensures that it withstands harsh environmental conditions, such as extreme temperatures and exposure to chemicals, which is particularly important in industries like mining, manufacturing, and construction.

Another significant benefit is its versatility. Crimped wire mesh is available in various sizes and can be cut or fabricated to meet specific project needs. Whether it’s used for fencing, screening, or filtration, crimped wire mesh can be tailored to fit almost any application. Additionally, its open structure allows for visible airflow and light passage, making it ideal for decorative purposes as well.

Applications of Crimped Wire Mesh

crimped wire mesh

Crimped wire mesh has a wide array of applications. In the construction industry, it is commonly used for reinforcing concrete, choosing to combine strength and versatility. Similarly, it can serve as protective barriers or enclosures, addressing safety and security concerns in industrial settings.

In landscaping and agriculture, crimped wire mesh is utilized for erosion control, seed germination mats, and as livestock fencing. Its ability to withstand environmental elements while maintaining structural integrity makes it a practical choice in these fields.

The filtration industry also benefits from crimped wire mesh. Its precise openings and customizable configurations allow it to efficiently separate particles in both liquids and gases. This is critical in sectors such as water treatment, food processing, and chemical production, where cleanliness and efficacy are paramount.

Considerations When Choosing Crimped Wire Mesh

When selecting crimped wire mesh for your project, several factors should be considered. First, determine the appropriate wire diameter and crimp pattern based on the mesh's intended use and the loads it must support. Additionally, consider the material and finish of the wire, especially if exposure to corrosive substances is involved.

Lastly, ensure that the mesh complies with relevant industry standards and regulations, particularly for applications in construction and food processing, where safety and compliance are non-negotiable.

Conclusion

Crimped wire mesh is a highly functional and adaptable solution for various industrial, agricultural, and construction needs. Its unique crimping process enhances its strength, stability, and versatility, allowing it to serve in multiple applications effectively. By understanding its characteristics and advantages, professionals can make informed decisions that leverage the benefits of crimped wire mesh in their respective fields. Whether for structural support, filtration, or decorative purposes, crimped wire mesh continues to be an essential material across many sectors.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025