-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 14, 2025 18:47 Back to list

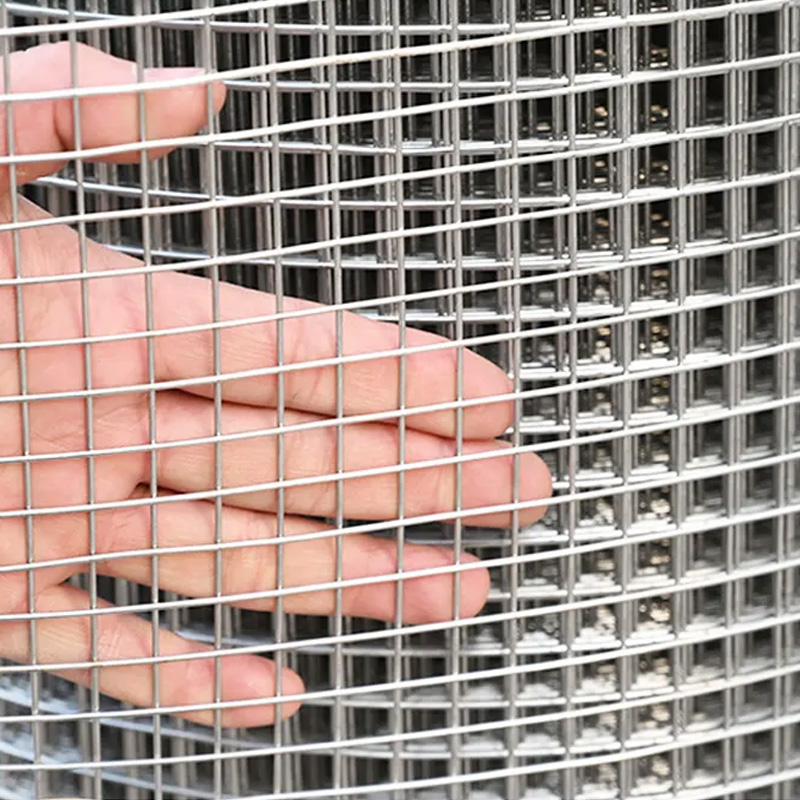

Crimped Wire Mesh

In the realm of industrial materials, custom crimped wire mesh stands out as a versatile and essential product, offering a range of applications across various sectors. With its intricate design and robustness, crimped wire mesh is particularly suitable for environments requiring durability and resilience. Understanding its unique characteristics and applications provides invaluable insights for industries seeking reliable solutions for their diverse needs.

From a reliability perspective, crimped wire mesh delivers unmatched performance due to its resistance to corrosion and wear. This attribute is particularly valuable in environments exposed to chemicals or moisture, where other materials may fail. The choice of materials in the manufacturing process, such as stainless steel or galvanized steel, further enhances the mesh’s longevity, making it a cost-effective solution over time. Authoritative knowledge in material science and engineering is crucial in the production of crimped wire mesh, ensuring consistency and excellence in the final product. Manufacturers bring years of expertise to the table, offering consultancy and tailored solutions that meet the specific needs of their clients, thereby contributing to the mesh’s reliability and trustworthiness as a product. In addition to its industrial applications, custom crimped wire mesh is also used in artistic endeavors and interior design, showcasing its versatility. Its unique patterns and structural beauty make it a choice material for creating decorative installations or modern design elements in architecture. This dual functionality enhances its appeal across different domains, proving its worth beyond conventional industrial applications. Trust in custom crimped wire mesh is built on a foundation of rigorous testing and quality assurance. Manufacturers adhere to international standards and regulations, ensuring that every piece of mesh produced meets the highest safety and quality criteria. This attention to detail instills confidence among users, knowing they are investing in a product that prioritizes safety and performance. In the ever-evolving landscape of industrial materials, custom crimped wire mesh remains a reliable and adaptable choice. Its combination of strength, customization, and durability positions it as a critical component in various applications, underscoring its importance and relevance in today’s market. As industries continue to seek solutions that balance functionality and cost-effectiveness, crimped wire mesh stands as a testament to innovative engineering and dedication to quality.

From a reliability perspective, crimped wire mesh delivers unmatched performance due to its resistance to corrosion and wear. This attribute is particularly valuable in environments exposed to chemicals or moisture, where other materials may fail. The choice of materials in the manufacturing process, such as stainless steel or galvanized steel, further enhances the mesh’s longevity, making it a cost-effective solution over time. Authoritative knowledge in material science and engineering is crucial in the production of crimped wire mesh, ensuring consistency and excellence in the final product. Manufacturers bring years of expertise to the table, offering consultancy and tailored solutions that meet the specific needs of their clients, thereby contributing to the mesh’s reliability and trustworthiness as a product. In addition to its industrial applications, custom crimped wire mesh is also used in artistic endeavors and interior design, showcasing its versatility. Its unique patterns and structural beauty make it a choice material for creating decorative installations or modern design elements in architecture. This dual functionality enhances its appeal across different domains, proving its worth beyond conventional industrial applications. Trust in custom crimped wire mesh is built on a foundation of rigorous testing and quality assurance. Manufacturers adhere to international standards and regulations, ensuring that every piece of mesh produced meets the highest safety and quality criteria. This attention to detail instills confidence among users, knowing they are investing in a product that prioritizes safety and performance. In the ever-evolving landscape of industrial materials, custom crimped wire mesh remains a reliable and adaptable choice. Its combination of strength, customization, and durability positions it as a critical component in various applications, underscoring its importance and relevance in today’s market. As industries continue to seek solutions that balance functionality and cost-effectiveness, crimped wire mesh stands as a testament to innovative engineering and dedication to quality.

Next:

Latest news

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025