-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 15, 2025 07:32 Back to list

Steel Grating

The demand for custom webforge steel grating has surged over the past few years, as industries widely recognize its unparalleled strength and adaptability for various applications. As a seasoned SEO specialist with deep industry insights, I want to guide you through understanding custom webforge steel grating prices, helping you make informed decisions.

Furthermore, market dynamics and raw material prices fluctuate and can impact the cost of webforge steel grating. Regular consultations with industry experts can help buyers anticipate these fluctuations and make proactive purchasing decisions. Reputable suppliers often update their clients on market changes, demonstrating their authority and reliability in the field. Installation is a crucial yet often overlooked element in pricing. Although sometimes included in the initial quote, installation costs can vary significantly based on location, complexity, and workforce requirements. Professional installation guarantees safety and performance while preventing future maintenance issues. Collaborating with installers experienced in custom webforge steel gratings ensures high-quality results and cost efficiency. Finally, suppliers' credibility plays a significant role in determining not just the price but the overall value. Trusted brands with a long-standing reputation for delivering quality products and services often offer better long-term value. They provide warranties, maintenance services, and excellent customer support, reinforcing their commitment to quality and customer satisfaction. When weighing pricing options, consider the supplier's reputation, client testimonials, and case studies showcasing successful projects. In conclusion, understanding custom webforge steel grating prices involves examining several factors including size, material, fabrication complexity, market conditions, and supplier credibility. Equipping yourself with expert knowledge allows for well-informed decisions, balancing cost and performance. Partnering with knowledgeable suppliers ensures that you receive grating solutions tailored to your needs with the assurance of safety, durability, and long-term value. The ultimate goal is to achieve seamless integration in your industrial environment, enhancing efficiency and security without disproportionate financial burden.

Furthermore, market dynamics and raw material prices fluctuate and can impact the cost of webforge steel grating. Regular consultations with industry experts can help buyers anticipate these fluctuations and make proactive purchasing decisions. Reputable suppliers often update their clients on market changes, demonstrating their authority and reliability in the field. Installation is a crucial yet often overlooked element in pricing. Although sometimes included in the initial quote, installation costs can vary significantly based on location, complexity, and workforce requirements. Professional installation guarantees safety and performance while preventing future maintenance issues. Collaborating with installers experienced in custom webforge steel gratings ensures high-quality results and cost efficiency. Finally, suppliers' credibility plays a significant role in determining not just the price but the overall value. Trusted brands with a long-standing reputation for delivering quality products and services often offer better long-term value. They provide warranties, maintenance services, and excellent customer support, reinforcing their commitment to quality and customer satisfaction. When weighing pricing options, consider the supplier's reputation, client testimonials, and case studies showcasing successful projects. In conclusion, understanding custom webforge steel grating prices involves examining several factors including size, material, fabrication complexity, market conditions, and supplier credibility. Equipping yourself with expert knowledge allows for well-informed decisions, balancing cost and performance. Partnering with knowledgeable suppliers ensures that you receive grating solutions tailored to your needs with the assurance of safety, durability, and long-term value. The ultimate goal is to achieve seamless integration in your industrial environment, enhancing efficiency and security without disproportionate financial burden.

Latest news

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

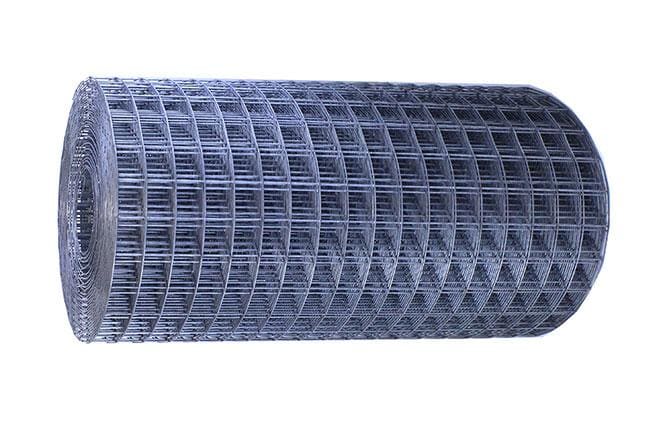

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025