-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 10, 2024 11:27 Back to list

expanded metal mesh manufacturer

Understanding the Role of Expanded Metal Mesh Manufacturers

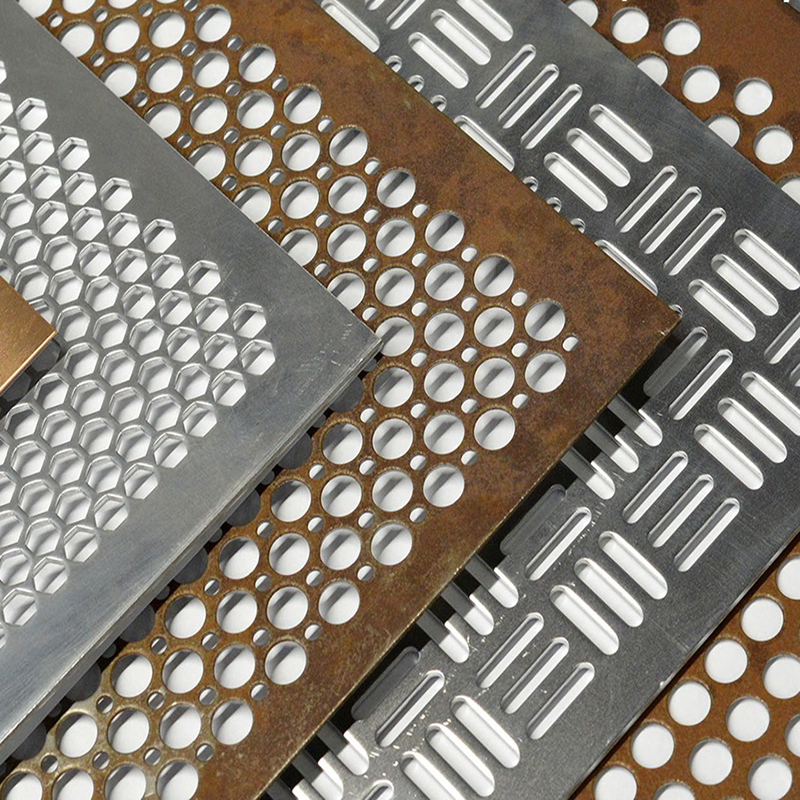

Expanded metal mesh is a versatile and highly functional material that has found applications across various industries due to its unique properties and aesthetic appeal. It is produced by taking a flat sheet of metal and cutting it in a specific pattern, which is then expanded into a diamond-shaped mesh. This manufacturing process not only increases the surface area but also enhances strength while maintaining lightweight characteristics. As industries evolve, the demand for customized and high-quality expanded metal mesh has surged, leading to the emergence of specialized manufacturers in this field.

The Manufacturing Process

The production of expanded metal mesh begins with selecting the right type of metal. Common materials include steel, aluminum, and stainless steel, each offering distinct advantages depending on the application. For instance, aluminum expanded metal is lightweight and resistant to corrosion, making it suitable for outdoor applications, while stainless steel is often preferred in environments that demand high durability and resistance to harsh chemicals.

Once the suitable material is selected, the sheet metal is subjected to a series of precise cuts using advanced machinery. The cutting process creates slits in the sheet, which can be adjusted to form varying patterns—ranging from small to large diamond shapes. After cutting, the material is mechanically expanded, increasing its size and transforming it into the mesh form. This process enhances the structural integrity of the mesh, allowing it to withstand significant loads.

Customization and Variability

One of the key advantages of working with expanded metal mesh manufacturers is the ability to customize products. Manufacturers can adjust factors such as the thickness of the metal, the size and shape of the openings, and the overall dimensions of the mesh to meet specific client requirements. This flexibility is particularly beneficial for industries such as construction, architecture, and automotive, where unique specifications are often needed for aesthetic or functional purposes.

Moreover, manufacturers can provide surface treatments such as powder coating, galvanization, or anodizing, which enhance not only the appearance of the mesh but also its resistance to corrosion and wear. These customizations allow expanded metal mesh to be used in a wide range of applications, from decorative architectural elements to security screens and filtration systems.

Applications of Expanded Metal Mesh

expanded metal mesh manufacturer

The applications of expanded metal mesh are vast and varied. In the construction industry, it is commonly used for reinforcing concrete structures due to its strength and durability. It serves as a lightweight alternative to traditional materials such as brick and concrete, making it an increasingly popular choice in modern architecture.

In the retail sector, expanded metal mesh is utilized in display racks and shelving, providing a blend of visibility and support for products. Its unique appearance also contributes to the contemporary aesthetic favored in many retail environments.

Furthermore, the manufacturing sector extensively employs expanded metal mesh for filtration and screening processes. Its excellent airflow characteristics facilitate the movement of air or liquid while maintaining a barrier against larger particles, making it ideal for industrial applications.

The Importance of Quality

When choosing an expanded metal mesh manufacturer, quality should be a top priority. High-quality materials and precise manufacturing processes result in a product that not only meets specifications but also performs reliably over time. Reputable manufacturers adhere to industry standards and regulations, ensuring that their products are safe and durable.

In addition to product quality, customer service plays a vital role in the success of a manufacturer. Effective communication, adherence to delivery schedules, and responsiveness to inquiries can significantly enhance the customer experience. Manufacturers that prioritize these aspects often build lasting relationships with clients across different sectors.

Conclusion

As the demand for expanded metal mesh continues to grow, the role of manufacturers in providing high-quality, customized solutions becomes increasingly important. With a focus on durability, versatility, and aesthetic appeal, expanded metal mesh serves as a crucial component in a multitude of industries. By collaborating with reliable manufacturers, businesses can ensure that they receive products that not only meet their needs but also contribute positively to their projects, paving the way for innovative applications and designs.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025