-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 09, 2024 20:35 Back to list

Expanded Wire Mesh Manufacturer for Durable and Versatile Construction Solutions

The Expanded Wire Mesh Factory A Comprehensive Overview

In today's modern industrial landscape, expanded wire mesh has emerged as a critical material utilized across various sectors ranging from construction to aerospace. The fabrication of this versatile product takes place in specialized factories dedicated to the production of expanded metal. This article delves into the workings of an expanded wire mesh factory, examining the manufacturing processes, applications, and benefits of this indispensable material.

Understanding Expanded Wire Mesh

Expanded wire mesh, also known as expanded metal, consists of sheets of metal that have been slotted or perforated and expanded to create a durable mesh structure. Made typically from materials such as steel, aluminum, or stainless steel, this unique product features a series of diamond-shaped openings that enhance both its strength and aesthetic appeal. Its properties make it lightweight yet robust, making it suitable for a broad array of applications.

The Manufacturing Process

The core process of producing expanded wire mesh involves several steps, all of which take place in a specialized factory setting. Here’s a breakdown of these essential stages

1. Material Selection The first step involves choosing the appropriate metal type. Factors such as corrosion resistance, weight requirements, and budget constraints influence this decision. Steel is often preferred due to its high tensile strength, while aluminum is chosen for its lightweight and corrosion-resistant properties.

2. Sheet Preparation Once the material has been selected, it is cut into sheets of the desired size. This initial cutting is vital as it determines the final dimensions of the expanded mesh.

3. Expanding Process The sheets are then fed into an expanding machine, which cuts and stretches the metal simultaneously. This innovative machine uses a series of sharp blades and rollers to create a pattern of slits along the sheet. As the metal is stretched, it expands to form the characteristic diamond-shaped openings.

4. Finishing Touches After expansion, the mesh may undergo various finishing processes to enhance its durability. This can include galvanizing to prevent rust, powder coating for additional protection, or simply cutting to specific dimensions required by customers.

5. Quality Control Rigorous quality control measures are implemented throughout the manufacturing stage. This involves inspecting the mesh for consistent size, shape, and structural integrity to ensure that it meets industry standards.

6. Packaging and Distribution Once the product passes quality inspections, it is carefully packaged and prepared for shipment. Many factories have partnerships with logistic companies to ensure timely delivery to customers across various regions.

Applications of Expanded Wire Mesh

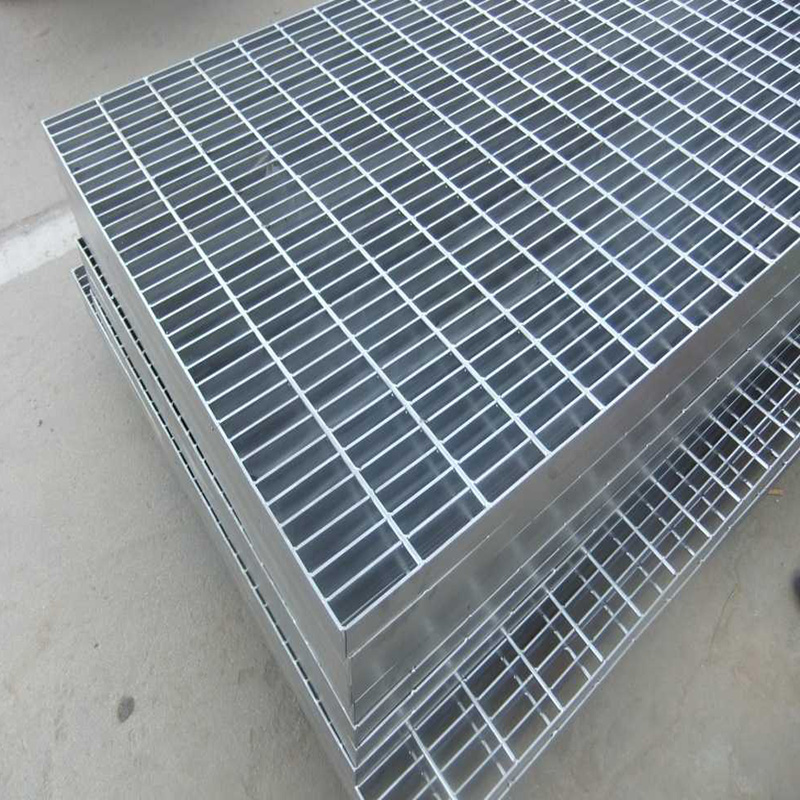

expanded wire mesh factory

The applications of expanded wire mesh are vast and varied, reflecting its versatility. Some common uses include

- Construction Expanded wire mesh is often employed as a supportive material in construction projects, providing reinforcement for concrete structures and serving as a barrier in facades and fencing

.- Industrial Uses Many industries utilize expanded metal for filtration systems, safety guards, and even as part of machinery for ventilation and air circulation purposes.

- Decorative Features In architectural design, expanded wire mesh is used for aesthetic elements, such as decorative facades, privacy screens, and artistic installations.

- Agricultural Applications Farmers often use expanded mesh for fencing, animal enclosures, and as trellises in horticulture, taking advantage of its durability and open design.

Benefits of Using Expanded Wire Mesh

The numerous benefits of expanded wire mesh are significant selling points for manufacturers and consumers alike

- Strength and Durability The process of expansion creates a structure that is not only lightweight but also exceptionally strong, capable of withstanding physical stress.

- Versatility With customizable sizes and shapes, expanded wire mesh can meet a variety of needs across multiple industries.

- Aesthetic Appeal The unique design of expanded metal adds a visually interesting element to products, making it a preferred choice in architectural applications.

- Cost-Effectiveness Due to its strength-to-weight ratio, expanded wire mesh can reduce costs in transportation and installation, providing a budget-friendly solution without compromising quality.

Conclusion

The expanded wire mesh factory plays an essential role in the production of this invaluable material, contributing to sectors that shape our world. Understanding the manufacturing process and the wide-ranging applications highlights the importance of expanded wire mesh in contemporary industry. With advancements in production technology and a commitment to quality, these factories are set to continue meeting the demands of various markets for years to come.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025