-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 31, 2024 21:21 Back to list

Factory for High-Quality Twisted Soft Annealed Iron Wire Production and Custom Solutions

The Art and Science of Twisted Soft Annealed Iron Wire Production

In the realm of industrial manufacturing, twisted soft annealed iron wire holds a unique and significant position. This product is essential in various applications, from crafting elegant art pieces to forming robust construction materials. The process of producing twisted soft annealed iron wire involves meticulous techniques that blend both art and science.

At the heart of this production is the choice of material. Soft annealed iron wire is prized for its malleability and ductility, qualities that allow for exceptional flexibility during twisting. The iron goes through an annealing process—a heat treatment that softens the material, making it easier to shape and manipulate. This is typically achieved by heating the wire to a specific temperature and then allowing it to cool slowly. This slow cooling process leads to a uniform microstructure that enhances the wire's workability.

Once the annealing is complete, the wire is ready for twisting. The twisting process itself is crucial for defining the wire's final attributes. The factory employs advanced machinery designed for precision twisting, ensuring that each wire strand is twisted evenly. This step not only contributes to the aesthetics of the wire but also affects its strength and reliability. Twisted soft annealed iron wire features a helical structure that enhances its tensile strength, making it a favored choice for various projects.

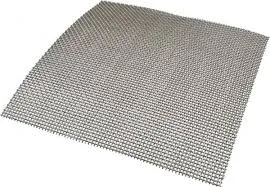

twisted soft annealed iron wire factory

Quality control is a pivotal aspect of the production process. Manufacturers must adhere to strict standards to ensure that the twisted wire meets the necessary specifications for different applications. This includes testing for flexibility, tensile strength, and resistance to corrosion. A rigorous inspection process guarantees that each batch of twisted wire is fit for use in construction, crafting, or any other intended application.

The applications of twisted soft annealed iron wire are vast. In the construction industry, it serves as a reliable reinforcement material for concrete structures. Its flexibility allows it to absorb stress and strain, ensuring the durability of buildings and infrastructure. Moreover, in the arts and crafts sector, artisans value twisted wire for creating intricate sculptures and designs. Its combination of strength and beauty enables creators to push the boundaries of their imagination.

Sustainability is also an increasingly important consideration in the manufacturing of twisted soft annealed iron wire. Many factories are adopting eco-friendly practices, such as reducing energy consumption and recycling materials. The iron used in the production can be sourced from recycled materials, contributing to a lower environmental impact. Innovations in production techniques aim to minimize waste and enhance energy efficiency further.

In conclusion, the production of twisted soft annealed iron wire is a fascinating intersection of art and industrial science. From the thoughtful selection of materials and thorough annealing processes to the precision of twisting and rigorous quality control, every step is essential to producing a product that is both versatile and reliable. As industries continue to evolve, the importance of twisted soft annealed iron wire remains steadfast, proving that even in a technology-driven world, traditional manufacturing techniques have their place in modern production. As we look ahead, it is clear that the craftsmanship behind twisted wire will continue to adapt, pushing the envelope in both functionality and aesthetics in countless applications.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025