-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 19, 2024 08:07 Back to list

Wire Mesh Fence Manufacturing Facility for Durable and Reliable Solutions

The Rise of Fence Mesh Wire Factories A Key Component in Modern Construction

In an era where urbanization and infrastructure development are at the forefront, fence mesh wire factories have emerged as unsung heroes in the construction industry. These specialized manufacturing units produce essential materials that play a crucial role in ensuring safety, security, and aesthetics in a variety of applications ranging from residential properties to industrial sites. This article explores the significance, process, and innovations in fence mesh wire manufacturing.

Understanding Fence Mesh Wire

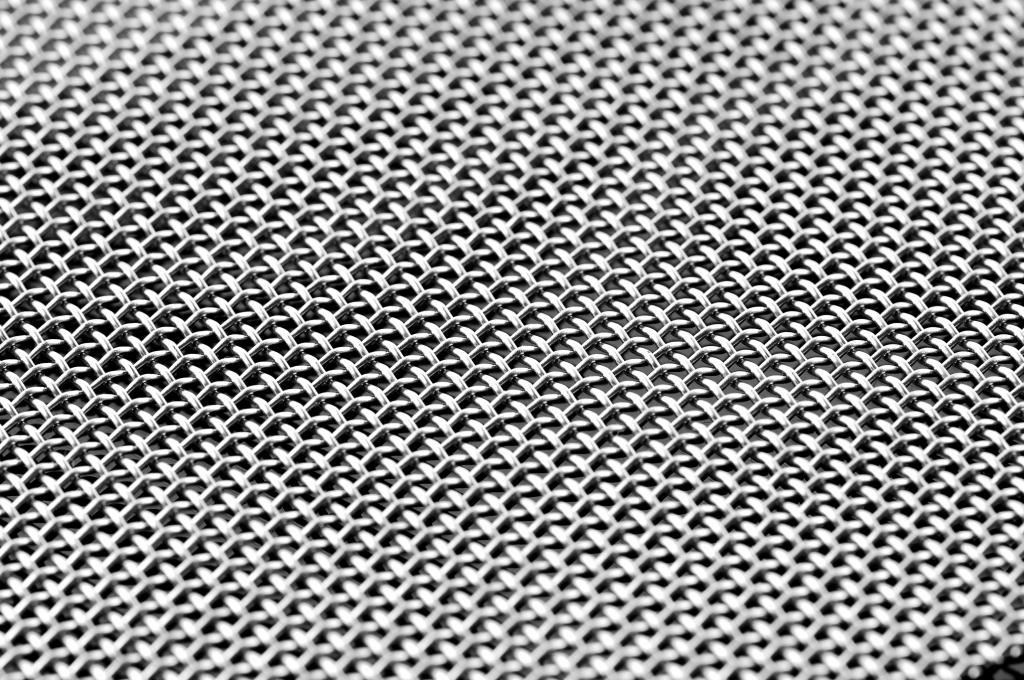

Fence mesh wire, commonly used in various fencing solutions, is typically made from steel or other metals. It is woven or welded to create a mesh structure that provides durability and support. Various types of mesh wire, such as welded wire, chain link, and barbed wire, serve different purposes, catering to diverse client needs. The versatility of fence mesh wire makes it indispensable in numerous sectors, including agriculture, construction, and landscaping.

The Manufacturing Process

Producing high-quality fence mesh wire involves several meticulous steps. The journey begins with the selection of raw materials, primarily steel wire, which undergoes rigorous quality checks. The wire is then processed, typically through either a welding or weaving technique, depending on the desired product.

1. Wire Drawing In this initial stage, larger steel rods are drawn into thinner wire strands through a series of dies. This stage is crucial in ensuring the strength and flexibility of the final product.

2. Mesh Formation The drawn wire is either welded together at intersections to form a rigid structure or woven into a flexible mesh. In welded wire mesh, the intersections are fused together using electric resistance, providing remarkable strength suitable for heavy-duty applications.

3. Surface Treatment To enhance durability and resistance to corrosion, the mesh is often treated with coatings such as galvanization (zinc coating) or PVC coating. This not only extends the lifespan of the mesh but also increases its aesthetic appeal.

4. Quality Control Throughout the manufacturing process, stringent quality control measures are employed. Each batch of mesh undergoes tests to ensure it meets industry standards and customer specifications.

fence mesh wire factory

5. Packaging and Distribution Finally, the finished products are carefully packaged and transported to various distribution channels, ready to meet the demands of construction and other sectors.

Innovations in Fence Mesh Wire Manufacturing

As industries evolve, so do the methods and technologies used in manufacturing. Modern fence mesh wire factories are increasingly adopting automation and smart technologies to enhance productivity and ensure consistent quality. Automated wire drawing machines and robotic welding systems are becoming commonplace, allowing for faster production rates and reduced labor costs.

Moreover, with the growing emphasis on sustainability, eco-friendly manufacturing processes are gaining traction. Many factories are now focusing on reducing waste and recycling materials, thereby minimizing their environmental impact. By utilizing renewable energy sources and implementing green practices, these factories are contributing to a more sustainable future.

Applications and Importance

The applications of fence mesh wire are diverse. In construction, it is used for reinforcing concrete structures, providing structural integrity to buildings, roads, and bridges. In agriculture, farmers use it to create enclosures for livestock and protect crops from pests. Moreover, it is crucial in security fencing for commercial properties, ensuring safety against intrusions.

Additionally, fence mesh wire plays a vital role in urban development. As cities expand, effective and aesthetically pleasing fencing solutions become necessary to delineate property lines, enhance privacy, and contribute to the overall landscape design.

Conclusion

The fence mesh wire factory represents a critical component of modern construction and infrastructure. Through skilled manufacturing processes and ongoing innovations, these factories produce materials that enhance safety, security, and aesthetic value in our environments. As urbanization continues to rise globally, the importance of quality fence mesh wire will only grow, affirming its essential role in shaping our built landscape. By embracing technological advancements and sustainable practices, fence mesh wire manufacturing is poised to meet the evolving demands of a dynamic future.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025