-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 30, 2024 15:55 Back to list

flexible and soft stainless steel wire mesh factory

The Versatility of Flexible and Soft Stainless Steel Wire Mesh A Comprehensive Overview

In an age where innovation meets functionality, the demand for versatile materials is ever-present. One such material that has gained immense popularity across various industries is flexible and soft stainless steel wire mesh. This unique product combines durability with adaptability, making it an essential choice for diverse applications ranging from architecture to industrial uses.

What is Flexible and Soft Stainless Steel Wire Mesh?

Flexible and soft stainless steel wire mesh is created from high-quality stainless steel, known for its corrosion resistance and strength. The mesh is engineered to provide both flexibility and softness, allowing it to be effortlessly molded into different shapes. Unlike rigid wire mesh, this version is more pliable, which enables it to perform well in applications that require bending or shaping without compromising its structural integrity.

Applications Across Various Industries

One of the most significant advantages of flexible and soft stainless steel wire mesh is its wide range of applications. In the architectural world, it is often used as a decorative facade, mesh ceilings, or as infill panels. The lightweight nature and aesthetic appeal allow architects to explore creative designs while ensuring durability and safety.

In the industrial sector, flexible wire mesh is crucial for filtering and separating materials. This mesh type can be tailored to various specifications, allowing it to trap particles of different sizes while maintaining a high flow rate. Applications in mining, food processing, and chemical industries often utilize this mesh for its effectiveness in filtration systems.

Moreover, flexible stainless steel wire mesh is indispensable in agriculture. It serves as a barrier for crops, protecting them from pests while allowing sunlight and airflow. Additionally, in the manufacturing sector, the mesh is employed as protective screens or safety barriers to ensure that machinery operates efficiently without the risk of hazards.

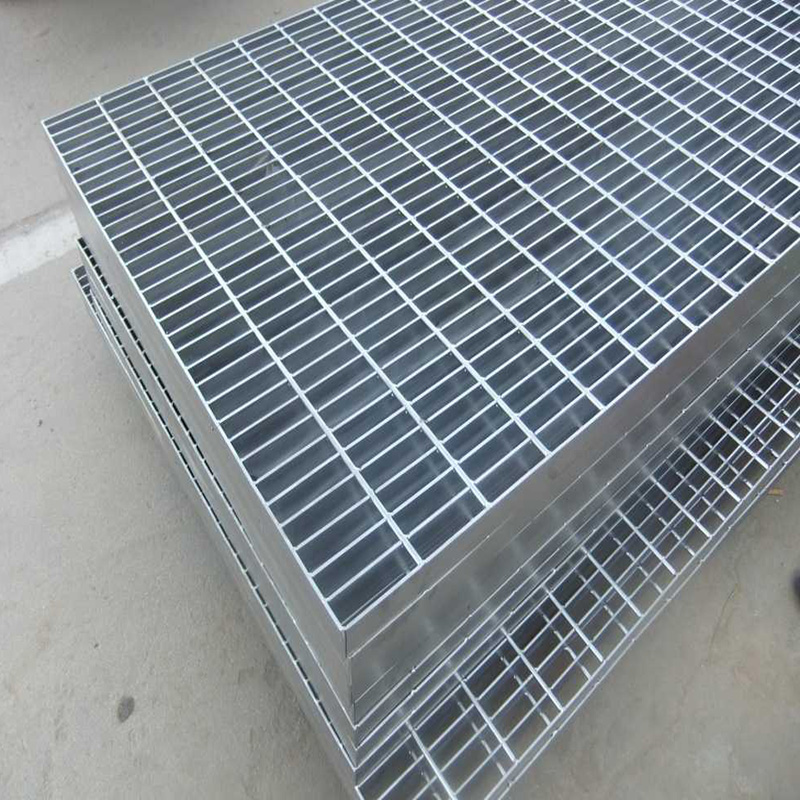

flexible and soft stainless steel wire mesh factory

Benefits of Using Flexible Stainless Steel Wire Mesh

The flexibility and softness of this wire mesh open up a plethora of benefits. Firstly, its ability to be reshaped without breaking makes it ideal for installations where modifications are necessary. This adaptability not only enhances the aesthetic attributes of products but also extends their lifespan by minimizing stress and strain.

Durability is another key advantage. Stainless steel is inherently resistant to rust and corrosion, ensuring that the mesh retains its functional properties over time, even in harsh environments. This longevity reduces the need for frequent replacements, thus offering cost savings in the long run.

Additionally, the ease of maintenance associated with stainless steel wire mesh cannot be overlooked. Unlike other materials that may require special cleaning agents or procedures, this mesh can simply be rinsed down with water, making it an efficient choice for busy environments.

Conclusion

As industries continue to evolve, the importance of flexible and soft stainless steel wire mesh cannot be overstated. Its adaptability, combined with the inherent qualities of stainless steel, ensures that it remains at the forefront of material choices for a multitude of applications. From architecture to agriculture, the versatile nature of this wire mesh exemplifies how functional materials enhance both aesthetic and operational performance. As the demand for such innovative solutions grows, the future of flexible stainless steel wire mesh looks bright, paving the way for new developments and applications across various fields.

Whether for industrial use or artistic design, flexible and soft stainless steel wire mesh is undoubtedly a hallmark of modern material sciences.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025