-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 01, 2024 01:17 Back to list

galvanised wire mesh factories

The Rise of Galvanised Wire Mesh Factories A Testament to Industrial Advancement

In recent years, the manufacturing sector has witnessed a significant evolution driven by technological advancements, global demands, and a growing emphasis on sustainability. Among the various products that have gained popularity in this era, galvanised wire mesh stands out due to its versatility, durability, and wide range of applications. This article delves into the emergence of galvanised wire mesh factories, exploring their significance, manufacturing processes, applications, and future potential.

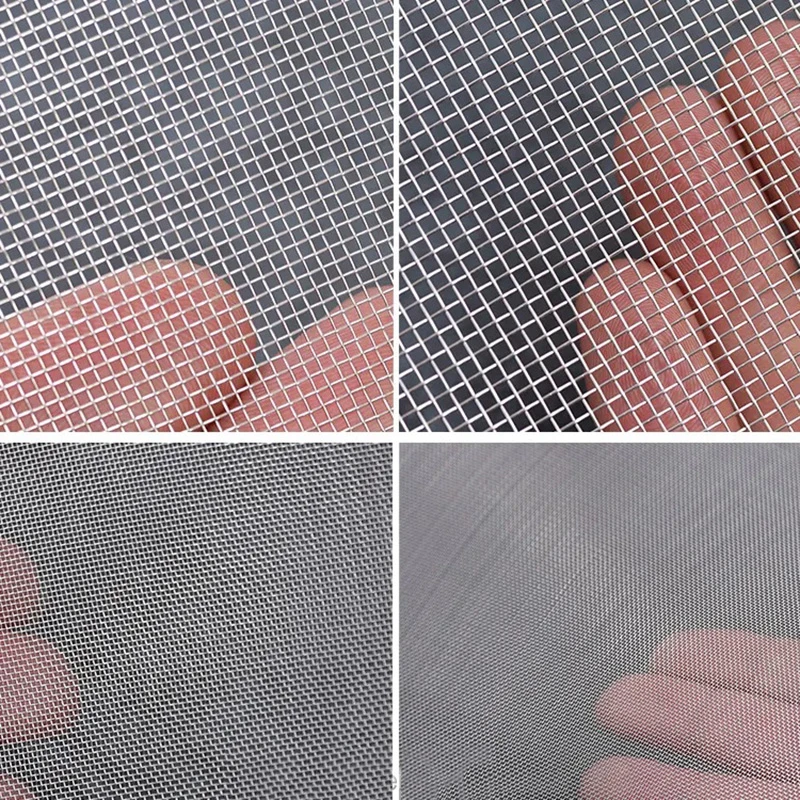

Understanding Galvanised Wire Mesh

Galvanised wire mesh is produced by coating steel wire with a layer of zinc, which serves as a protective barrier against corrosion. This process, known as galvanization, ensures that the wire mesh can withstand harsh environmental conditions, making it ideal for various applications. The mesh is typically available in different sizes, gauges, and configurations, catering to a multitude of needs across sectors such as construction, agriculture, and industrial applications.

The Manufacturing Process

The production of galvanised wire mesh involves several key steps

1. Wire Drawing The process begins with wire drawing, where raw steel is drawn through a series of dies to produce wires of specific diameters. High-quality steel is essential for ensuring the durability and strength of the final product.

2. Galvanization Once the wires are drawn, they undergo the galvanization process. This can be done through hot-dip galvanization, where the wires are submerged in molten zinc, or electro-galvanization, which involves applying a zinc coating using electrical currents. Hot-dip galvanization is the preferred method for its ability to provide a thicker, more robust protective layer.

3. Mesh Weaving After galvanization, the coated wires are woven together into a mesh pattern. This process can vary depending on the desired specifications, with options for different weave types like welded, crimped, or woven.

4. Finishing The final product undergoes quality control to ensure it meets industry standards. Additional treatments, such as cutting, bending, or coating with other materials, may be applied based on the specific application requirements.

Applications of Galvanised Wire Mesh

The versatility of galvanised wire mesh allows it to be utilized in numerous fields, including

galvanised wire mesh factories

- Construction In the construction industry, galvanised wire mesh is commonly used in reinforcing concrete, providing structural support in buildings, bridges, and roads. It is also employed in fencing and as protective barriers.

- Agriculture Farmers rely on galvanised wire mesh for fencing, animal enclosures, and crop protection. Its durability and resistance to rust make it an excellent choice for outdoor applications.

- Industrial Uses In manufacturing and industrial settings, galvanised wire mesh is used for filtration, sieving, and as safety barriers in machine environments. Its strength and longevity contribute significantly to workplace safety.

The Impact of Galvanised Wire Mesh Factories

The rise of galvanised wire mesh factories has not only created numerous job opportunities but has also played a vital role in promoting local economies. As demand for galvanised wire mesh increases, these factories invest in advanced technologies and skilled labor, enhancing production efficiency and product quality.

Moreover, the establishment of these factories has led to a decrease in import reliance, empowering local businesses to meet the growing demands of various industries. The strategic positioning of these factories near raw material sources also reduces transportation costs and carbon footprints, aligning with global efforts toward sustainability.

The Future of Galvanised Wire Mesh Manufacturing

Looking ahead, the galvanised wire mesh manufacturing sector is poised for growth. With the increasing emphasis on sustainable construction practices and the demand for raw materials that can withstand climate challenges, galvanised wire mesh is becoming a preferred choice across a multitude of industries.

Innovations in production technologies, along with a focus on eco-friendly practices, will further enhance the appeal of galvanised wire mesh. Additionally, the rise of smart manufacturing and automation could provide manufacturers with the tools to optimize processes, reduce waste, and improve product consistency, ensuring that galvanised wire mesh remains a staple in the industry.

Conclusion

The emergence of galvanised wire mesh factories marks a significant advancement in manufacturing. As industries continue to evolve and seek robust, reliable materials, galvanised wire mesh is well-positioned to meet these demands, offering both quality and versatility. The continued growth of these factories not only symbolizes industrial progress but also heralds a future where sustainable practices and innovative technologies drive manufacturing to new heights.

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025