-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 11, 2024 09:52 Back to list

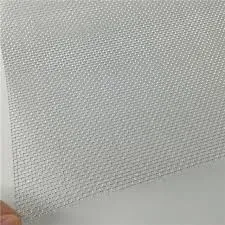

Galvanized Square Woven Wire Mesh Export Suppliers and Manufacturers Worldwide

The Export Landscape of Galvanized Square Woven Wire Mesh

In today's global marketplace, the demand for high-quality materials has surged across various industries, including construction, agriculture, and fencing. One product that has been steadily gaining prominence is galvanized square woven wire mesh. This versatile and durable material has become a staple for many applications, leading to a booming export sector for manufacturers around the world.

What is Galvanized Square Woven Wire Mesh?

Galvanized square woven wire mesh is made by weaving together strands of wire that have undergone galvanization—a process of coating iron or steel wire with a protective layer of zinc. This coating serves to prevent rust, corrosion, and deterioration, which can be particularly beneficial in environments exposed to moisture or extreme weather conditions. The square designation refers to the uniformity in the size of the openings within the mesh, making it an ideal choice for applications that require precise spacing and strength.

Applications Across Industries

The uses of galvanized square woven wire mesh are numerous. In the construction sector, it serves as reinforcement in concrete, helping to provide additional strength to structures. In the agricultural field, it is commonly employed in fencing solutions, allowing for secure enclosures that protect livestock and crops from predators and environmental damage. Furthermore, the mesh finds applications in industrial settings, such as filtration systems and machine guards, due to its robustness and reliability.

Export Trends and Opportunities

The export market for galvanized square woven wire mesh is expanding rapidly. Countries with robust manufacturing sectors, such as China, the United States, and various nations in Europe, are major producers and exporters of this product. The growing need for reliable materials in developing countries further stimulates demand, creating a wealth of opportunities for suppliers and exporters.

galvanized square woven wire mesh exporter

For instance, emerging economies, particularly in Asia and Africa, are witnessing infrastructure developments that require durable construction materials. The need for fencing in agricultural projects and wildlife protection is also increasing. As a result, exporters are strategically positioned to supply this market, creating lucrative partnerships and expanding their reach.

Quality Assurance and Standards

The international marketplace expects high standards in product quality, particularly for materials like galvanized square woven wire mesh. Compliance with various international testing and certification norms is essential for exporters. Adhering to quality standards not only ensures the safety and durability of the mesh but also enhances the reputation of manufacturers in the global arena. Choosing high-quality steel and employing best practices in galvanization are critical steps in ensuring that the final product meets the required specifications.

Challenges in the Export Market

However, exporters must navigate various challenges within the export landscape. Tariffs, trade agreements, and currency fluctuations can impact profitability and competitiveness. Additionally, it can be challenging to keep up with increasing regulations in different countries, such as environmental standards governing production methods. To remain competitive, exporters must stay informed about market trends and adapt their strategies accordingly.

The Future of Galvanized Square Woven Wire Mesh Exporting

As the world becomes more interconnected, the future of galvanized square woven wire mesh exporting looks bright. Innovations in manufacturing techniques and growing awareness of the benefits of galvanized products will likely lead to increased demand. Furthermore, exporters who prioritize sustainability by implementing eco-friendly practices in their production processes will find themselves at a significant advantage.

In conclusion, the export sector for galvanized square woven wire mesh is poised for growth, driven by its diverse applications and the increasing global emphasis on quality and durability. By focusing on high standards, navigating challenges effectively, and embracing innovation, exporters can capitalize on this burgeoning market and secure a competitive edge in the global supply chain.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025