-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 21, 2024 03:01 Back to list

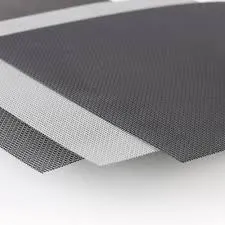

Wire Mesh Production Facility Specializing in Galvanized Products for Diverse Applications

The Importance of Galvanized Wire Mesh and Its Manufacturing Process

Galvanized wire mesh is a versatile and essential material widely used in various industries, including construction, agriculture, and transportation. Its durability, corrosion resistance, and strength make it an ideal choice for a multitude of applications. In this article, we will explore the significance of galvanized wire mesh, the manufacturing process, and the key factors to consider when choosing a galvanized wire mesh factory.

Understanding Galvanization

Galvanization is the process of applying a protective zinc coating to iron or steel to prevent Corrosion. This method is essential in prolonging the life of wire mesh products, particularly in outdoor or industrial environments where exposure to moisture and harsh conditions is common. The galvanization process can involve either hot-dip galvanizing, where the metal is submerged in a molten zinc bath, or electro-galvanizing, where an electric current is used to deposit zinc onto the surface.

The result of this process is a wire mesh that exhibits exceptional resistance to rust, wear, and tear. This durability is particularly crucial in applications such as fencing, reinforcement for concrete, and separation of materials in construction sites or industrial settings.

Applications of Galvanized Wire Mesh

Galvanized wire mesh is used in various applications due to its strength and durability. In the construction sector, it serves as reinforcement for concrete structures, providing additional tensile strength and helping prevent cracks. It is also commonly used in the creation of fences for residential, agricultural, and industrial purposes, as it offers an effective barrier against intruders and animals.

In agriculture, galvanized wire mesh is utilized for creating animal enclosures and protective fencing around crops. Its ability to withstand harsh weather conditions makes it an ideal choice for these applications. Additionally, in the mining industry, galvanized wire mesh is used for screening and separating materials, ensuring efficient operations.

The Manufacturing Process of Galvanized Wire Mesh

The manufacturing of galvanized wire mesh involves several key steps

1. Wire Drawing The process begins with wire drawing, where large coils of steel wire are pulled through reducing dies to achieve the desired thickness. This step is crucial as it determines the wire's diameter and mechanical properties.

2. Cleaning The drawn wire is then cleaned to remove any impurities or oxidation. A clean surface is essential for effective galvanization, ensuring proper adhesion of the zinc coating.

galvanized wire mesh factory

3. Galvanization The cleaned wire is subjected to the galvanization process. In hot-dip galvanizing, the wire is immersed in molten zinc, while in electro-galvanizing, it is coated with zinc using an electrical current. The layer of zinc acts as a barrier against environmental elements.

4. Mesh Weaving Once galvanized, the wire is woven into a mesh pattern. The weaving process can vary in size and pattern, depending on the intended application.

5. Finishing After weaving, the galvanized wire mesh undergoes a finishing process, which may include cutting to specific sizes, packaging, and quality control inspections.

6. Distribution Finally, the finished mesh is prepared for distribution to customers. Quality assurance is critical at this stage to ensure that the product meets the required standards and specifications.

Choosing the Right Galvanized Wire Mesh Factory

When selecting a galvanized wire mesh factory, several factors should be considered

- Quality Standards Ensure that the factory adheres to international quality standards and certifications, guaranteeing the durability and reliability of its products.

- Production Capacity Depending on your needs, consider the factory's production capacity and turnaround times.

- Customization Options Look for a manufacturer that offers customization in terms of mesh size, wire thickness, and coating options to meet specific requirements.

- Customer Service Good customer service and support can provide valuable guidance and assistance throughout the purchasing process.

In conclusion, galvanized wire mesh plays a crucial role in various industries due to its strength and resistance to corrosion. Understanding the manufacturing process and choosing the right factory is essential for ensuring that you receive a product that meets your needs and expectations. Whether for construction, agriculture, or other applications, investing in high-quality galvanized wire mesh is a decision that pays off in the long run.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025