-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 19, 2024 13:22 Back to list

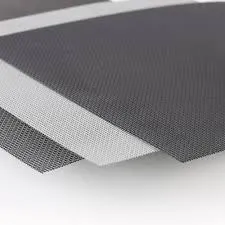

galvanized woven wire mesh exporters

The Growing Market of Galvanized Woven Wire Mesh A Focus on Exporters

In the rapidly evolving global marketplace, galvanized woven wire mesh has emerged as a vital commodity, particularly in industries such as construction, agriculture, and manufacturing. Characterized by its corrosion-resistant properties, galvanized woven wire mesh serves numerous applications, including fencing, animal enclosures, and as support structures. This article explores the role of exporters in this growing market, their significance, and the trends shaping the industry.

Understanding Galvanized Woven Wire Mesh

Galvanized woven wire mesh is created by weaving together steel wires that have been coated with a layer of zinc to prevent rust and corrosion. This manufacturing process not only enhances the mesh's durability but also increases its lifespan, making it an ideal choice for outdoor applications. The mesh is available in various sizes and hole configurations, making it versatile for multiple uses across different sectors.

The Role of Exporters

Exporters of galvanized woven wire mesh play a crucial role in meeting global demand. These companies facilitate the movement of products from manufacturing hubs to international markets, ensuring that various industries have access to high-quality materials. Their operations often include sourcing from local manufacturers, adhering to international quality standards, and understanding the regulatory requirements of different countries.

In recent years, the demand for galvanized woven wire mesh has surged, particularly in regions experiencing rapid urbanization and industrial development. Exporters are pivotal in connecting producers with customers worldwide, thereby expanding market reach and fostering economic growth in their respective regions.

Market Trends

galvanized woven wire mesh exporters

Several trends are shaping the galvanized woven wire mesh export market. First, there’s an increasing awareness of the benefits of using galvanized products over non-galvanized options. The demand for eco-friendly materials is prompting manufacturers to explore sustainable production practices, which include using recycled materials in the creation of wire mesh.

Secondly, technological advancements in manufacturing processes are enabling exporters to offer customized solutions. This flexibility allows clients to specify wire diameter, mesh size, and coating thickness, further driving demand across sectors like agriculture (for livestock fencing) and construction (for reinforcement applications).

Thirdly, the rise of e-commerce has revolutionized the export landscape. Many exporters now leverage online platforms to reach international clients directly, thereby increasing competition and providing consumers with more choices. This shift not only benefits the exporters but also empowers buyers by offering transparency in pricing and product specifications.

Challenges Faced by Exporters

Despite the promising landscape, exporters of galvanized woven wire mesh face several challenges. Fluctuating raw material prices, such as steel and zinc, can significantly affect profitability. Additionally, trade policies and tariffs can impose restrictions that complicate international transactions. Exporters need to remain agile, adapting to changing regulations and market demands to sustain growth.

Moreover, ensuring quality control throughout the supply chain is vital. Establishing strong relationships with manufacturers and maintaining stringent quality assurance protocols are essential for maintaining reputation and customer trust.

Conclusion

Galvanized woven wire mesh exporters occupy a pivotal position in the global supply chain, meeting the needs of diverse industries with high-quality products. As the market evolves, exporters must navigate challenges while capitalizing on emerging opportunities. By embracing technological advancements and adhering to sustainable practices, they can continue to thrive in the competitive landscape and contribute to industrial growth on a global scale. The future looks promising for those engaged in this sector, as the demand for durable and versatile materials remains robust across the world.

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025

-

Reliable Perforated Stainless Steel Sheets Custom Designs & Export

NewsJun.09,2025

-

Top PVC Garden Fences for Durability & Style Suppliers

NewsJun.08,2025

-

Premium Field Fence Wire - Durable & Affordable Solutions

NewsJun.08,2025