-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 20, 2024 13:08 Back to list

grating steel factory

The Revival of Grating Steel Factories An Essential Component in Modern Infrastructure

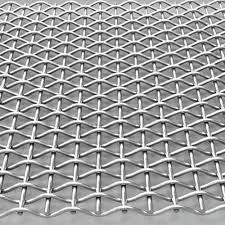

Grating steel factories have emerged as pivotal contributors to the construction and manufacturing sectors, playing an essential role in producing industrial grating systems that cater to various applications. These products, characterized by their durable design and exceptional load-bearing capacity, are critical in a multitude of environments, from manufacturing plants to pedestrian walkways. In the face of rapid industrialization and infrastructure development, the relevance of grating steel factories has never been more pronounced.

At the heart of grating steel production is the process of manufacturing steel grating, which involves the strategic positioning of steel bars to create a strong, yet lightweight structure. These grates are engineered to provide adequate ventilation, drainage, and access while ensuring safety and stability under heavy loads. Common applications include flooring, drainage covers, platforms, and stair treads, utilized in commercial, industrial, and municipal projects.

The Revival of Grating Steel Factories An Essential Component in Modern Infrastructure

Another compelling aspect of grating steel is its versatility. Factories produce a variety of grating types, including welded, swage-lock, and press-locked, each tailored for specific needs. For instance, heavy-duty grates are often employed in automotive manufacturing facilities, allowing for the weight of vehicles to be supported without compromising safety. In contrast, light-duty grates may be suitable for pedestrian walkways in parks or public plazas, showcasing the adaptability of steel grating to different load specifications and usage scenarios.

grating steel factory

The environmental impact of grating steel factories is also a crucial consideration in today’s industrial landscape. With increasing emphasis on sustainability, many manufacturers are now adopting eco-friendly practices by utilizing recycled steel in their production processes. Steel is infinitely recyclable, meaning it can be repurposed without losing quality, thus contributing to a circular economy. Additionally, modern factories are investing in energy-efficient technologies and processes to reduce their carbon footprint, demonstrating a commitment to environmental stewardship.

In the context of global economic trends, grating steel factories are poised for significant growth. As nations invest heavily in infrastructure projects, from transportation networks to urban development, the demand for reliable and durable building materials continues to rise. Moreover, the ongoing transition toward industrial automation in factories is enhancing production efficiency, allowing for higher output while maintaining quality standards.

However, the industry is not without its challenges. Fluctuating raw material prices and supply chain disruptions can affect production costs and timelines. Moreover, the competition from alternative materials, such as fiberglass grating, poses questions regarding the market share of traditional steel products. Nevertheless, the inherent strengths of steel—in terms of strength, durability, and versatility—afford it a competitive edge that is hard to replicate.

In conclusion, grating steel factories stand as vital contributors to modern infrastructure, providing essential products that combine strength, durability, and versatility. With the continued growth of urbanization and industrialization, the demand for grating steel is expected to rise. As these factories innovate and adapt to environmental concerns and market dynamics, they reinforce their crucial role in supporting the frameworks of our built environment. The evolution and efficiency of grating steel production will undeniably play a significant part in shaping sustainable infrastructure for generations to come.

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025