-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 26, 2024 13:53 Back to list

High-Quality Galvanized Iron Wire Production with Advanced Technology in Our Manufacturing Facility

The Importance of Galvanized Iron Wire Manufacturing

Galvanized iron wire is an essential material used in various applications, from construction and agriculture to industrial settings. The manufacturing process of galvanized iron wire is crucial, not only for ensuring the product's quality and durability but also for meeting the demands of the diverse industries that rely on it. In this article, we will explore the significance of galvanized iron wire factories, the manufacturing process, and its applications.

What is Galvanized Iron Wire?

Galvanized iron wire is a type of steel wire that has been coated with a layer of zinc to protect it from rust and corrosion. The galvanization process enhances the wire's durability, making it suitable for outdoor and industrial usage. The wire is typically produced in various gauges, offering versatility for different applications.

The Manufacturing Process

The manufacturing of galvanized iron wire usually involves several key stages. Initially, high-quality steel wire is drawn through a series of dies to achieve the desired thickness. This wire is cleaned meticulously to remove any impurities, oils, or other contaminants that may affect the quality of the zinc coating.

Once cleaned, the wire undergoes a galvanization process. There are two primary methods for galvanizing hot-dip galvanizing and electro-galvanizing. In hot-dip galvanizing, the wire is submerged in molten zinc, which forms a thick, durable coating. Conversely, electro-galvanizing involves the deposition of zinc onto the wire through an electrochemical process, resulting in a thinner coating but often a more uniform finish.

After galvanization, the wire is left to cool and is subsequently tested for quality. This quality control is vital, as it ensures that the wire meets industry standards for strength, flexibility, and corrosion resistance. Finally, the galvanized wire can be cut into required lengths, spooled, or packaged for distribution.

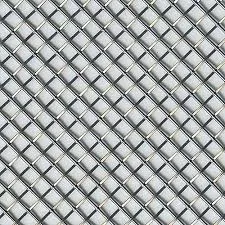

galvanized iron wire factory

Applications of Galvanized Iron Wire

The versatility of galvanized iron wire has led to its widespread use across various sectors. In construction, it serves as reinforcement for concrete, fencing, and scaffolding. Its resistance to rust makes it an ideal choice for outdoor applications, such as garden fencing and trellises.

In agriculture, galvanized wire is used in the construction of fencing to protect livestock and crops. Its durability ensures that it can withstand harsh weather conditions, making it a reliable choice for farmers.

Industrial applications also heavily utilize galvanized wire. It is frequently employed in the manufacturing of mesh products, wire ropes, and binding wire, which are essential in various construction and engineering tasks. Additionally, galvanized wire products are often found in electrical applications, providing reliable connections that resist corrosion.

Environmental Considerations

Galvanized iron wire manufacturers are increasingly adopting environmentally friendly practices. By implementing recycling programs for scrap materials and optimizing production processes to reduce waste, factories contribute to sustainability efforts. Furthermore, the durability of galvanized wire means it does not need to be replaced as frequently, thereby reducing the overall environmental impact associated with production and disposal.

Conclusion

Galvanized iron wire factories play a crucial role in producing a material that supports various industries while ensuring quality and durability. As demand continues to grow, the importance of innovation and sustainability within the manufacturing process will become increasingly vital. By maintaining strict quality control and adopting eco-friendly practices, these factories can continue to provide essential products that meet the evolving needs of the market. Whether for construction, agriculture, or industrial purposes, galvanized iron wire remains a valuable material in our everyday lives.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025