-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 06, 2024 12:21 Back to list

High-Quality PVC Coated Wire Mesh Rolls from Leading Manufacturing Facility for Various Applications

PVC Coated Wire Mesh Roll A Versatile Solution from the Factory

PVC coated wire mesh rolls have become an essential component in various industries due to their durability, versatility, and aesthetic appeal. The manufacturing process of these wire meshes involves coating high-quality steel wires with polyvinyl chloride (PVC), which enhances their performance and longevity. This article explores the benefits, applications, and features of PVC coated wire mesh rolls produced in modern factories.

The Manufacturing Process

The production of PVC coated wire mesh starts with the selection of high-tensile steel wire. The wire is then woven into a mesh pattern, which can consist of different aperture sizes depending on the intended use. After weaving, the wire is coated with a layer of PVC, which is typically applied through a process known as extrusion. This method ensures a uniform coating that adheres tightly to the wire, providing excellent resistance against corrosion, weather elements, and physical damage.

The factories specializing in PVC coated wire mesh rolls often employ advanced machinery and technology to maintain high-quality standards. This includes precise control over the coating process to ensure durability and longevity in the final product. Factories typically conduct rigorous quality checks to ensure that the wire mesh meets the required specifications before it is rolled and shipped to customers.

Benefits of PVC Coated Wire Mesh

1. Corrosion Resistance One of the primary advantages of PVC coated wire mesh is its resistance to rust and corrosion. The PVC layer acts as a barrier, protecting the underlying metal from moisture and environmental factors. This prolongs the lifespan of the mesh, making it suitable for outdoor applications.

2. Aesthetic Appeal The availability of various colors in PVC coatings allows customers to select wire mesh that suits their project’s aesthetics. This is particularly useful in landscaping and residential applications, where visual appeal is essential.

3. Safety and Security PVC coated wire mesh offers a higher degree of safety as the coating reduces sharp edges and makes handling easier. This is particularly important in environments where children or pets may be present.

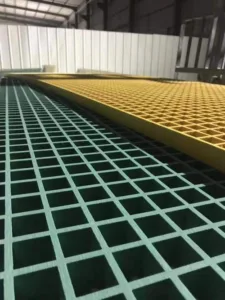

pvc coated wire mesh roll factory

4. Flexibility in Use The versatility of PVC coated wire mesh rolls allows them to be used in a wide range of applications, including fencing, garden enclosures, agricultural sectors, and industrial settings. The ability to customize the mesh size and gauge makes it adaptable to specific needs.

Applications

PVC coated wire mesh rolls find applications in several fields

- Agriculture They are commonly used for fencing around farms to protect crops and livestock from intruders and predators, ensuring a secure environment for agricultural activities.

- Construction In the construction industry, these wire meshes are used for reinforcing concrete structures and as protective barriers on construction sites.

- Residential Homeowners utilize PVC coated wire mesh for garden enclosures, pet containment, and decorative fencing, benefiting from both functionality and visual appeal.

- Industrial In industrial settings, wire mesh rolls may serve as partitions, safety guards, or even shelving in warehouses, illustrating their versatility.

Conclusion

PVC coated wire mesh rolls produced in factories represent a combination of functionality, durability, and aesthetic appeal. Whether for agricultural, industrial, or residential use, these products prove to be an invaluable resource. As technology advances, the quality and applications of PVC coated wire mesh continue to evolve, making them an increasingly popular choice in many sectors. By choosing high-quality PVC coated wire mesh from reputable factories, users can ensure they are investing in products that will deliver durability and performance over time.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025