-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 17, 2025 15:00 Back to list

Insect Screening

Aluminum has long been celebrated for its combination of strength and lightweight properties, propelling its use in a myriad of industries including construction, automotive, and aerospace. Among the various forms of aluminum available, high-quality aluminum perforated sheets stand out due to their versatility and functionality. This article will delve into the real-world applications, benefits, and engineering expertise behind the production of these perforated sheets, showcasing their undeniable value across a range of sectors.

In addition to these visible benefits, the production of high-quality aluminum perforated sheets demands a high level of expertise and precision engineering. Manufacturers employ advanced machinery that guarantees uniform perforations and meticulous finishing treatments to ensure edges are smooth and safe for handling. The use of top-grade aluminum alloys further reinforces the product’s strength and longevity, promising clients a superior product designed to meet strict quality standards. Trust in the product is further built through rigorous testing and certifications, supporting the material’s structural claims and environmental compliance. Industry standards such as ISO certifications solidify the sheets' status as reliable components for diverse applications. For clients and businesses, this adherence to standards translates into peace of mind, knowing they are investing in materials that uphold both safety and functionality. Moreover, the sustainable nature of aluminum as a material aligns with the global push towards eco-friendly practices. Aluminum is 100% recyclable, and recycling consumes only a fraction of the energy required to produce primary aluminum. This property makes perforated aluminum sheets an attractive choice for project engineers and designers aiming to reduce their environmental footprint. The trustworthiness of aluminum perforated sheets also lies in the established history of partnerships between manufacturers and clients. By fostering transparent relationships based on accountability and customer satisfaction, producers ensure continued excellence and innovation in developing these versatile materials. Clients often have dedicated support teams offering advice and solutions tailored to their specific project needs, further accentuating the sheets’ authoritative status in the market. In conclusion, high-quality aluminum perforated sheets represent a fusion of art, science, and sustainable practice. Their multifaceted applications in architecture, automotive, and beyond are a testament to their unparalleled versatility and efficacy. With a foundation built on expertise and trust, these sheets continue to lead the way in modern engineering and design, promising continued relevance in a world ever-evolving in its demand for innovative solutions.

In addition to these visible benefits, the production of high-quality aluminum perforated sheets demands a high level of expertise and precision engineering. Manufacturers employ advanced machinery that guarantees uniform perforations and meticulous finishing treatments to ensure edges are smooth and safe for handling. The use of top-grade aluminum alloys further reinforces the product’s strength and longevity, promising clients a superior product designed to meet strict quality standards. Trust in the product is further built through rigorous testing and certifications, supporting the material’s structural claims and environmental compliance. Industry standards such as ISO certifications solidify the sheets' status as reliable components for diverse applications. For clients and businesses, this adherence to standards translates into peace of mind, knowing they are investing in materials that uphold both safety and functionality. Moreover, the sustainable nature of aluminum as a material aligns with the global push towards eco-friendly practices. Aluminum is 100% recyclable, and recycling consumes only a fraction of the energy required to produce primary aluminum. This property makes perforated aluminum sheets an attractive choice for project engineers and designers aiming to reduce their environmental footprint. The trustworthiness of aluminum perforated sheets also lies in the established history of partnerships between manufacturers and clients. By fostering transparent relationships based on accountability and customer satisfaction, producers ensure continued excellence and innovation in developing these versatile materials. Clients often have dedicated support teams offering advice and solutions tailored to their specific project needs, further accentuating the sheets’ authoritative status in the market. In conclusion, high-quality aluminum perforated sheets represent a fusion of art, science, and sustainable practice. Their multifaceted applications in architecture, automotive, and beyond are a testament to their unparalleled versatility and efficacy. With a foundation built on expertise and trust, these sheets continue to lead the way in modern engineering and design, promising continued relevance in a world ever-evolving in its demand for innovative solutions.

Latest news

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

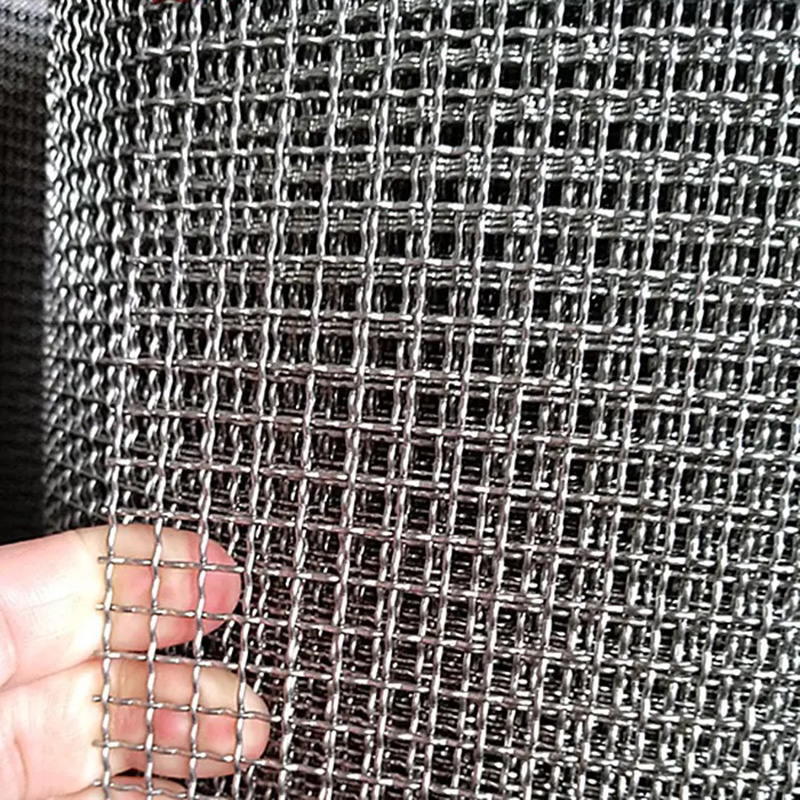

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025