-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 23, 2024 19:27 Back to list

Understanding the Benefits of Hot Dipped Galvanized Wire for Construction and Fencing Applications

Understanding Hot Dipped Galvanized Wire Advantages and Applications

Introduction

Hot dipped galvanized wire plays a crucial role in various industries with its remarkable durability and resistance to corrosion. This wire, which is coated in a protective layer of zinc through a hot immersion process, is widely used in applications ranging from construction to agriculture. In this article, we will explore what hot dipped galvanized wire is, its manufacturing process, advantages, and common applications.

What is Hot Dipped Galvanized Wire?

Hot dipped galvanized wire is a type of wire that has undergone a galvanization process to enhance its resistance to rust and corrosion. The process involves cleaning the wire and then immersing it in molten zinc, forming a robust metallic coating. This coating provides a barrier against moisture and other corrosive elements, making it suitable for outdoor use.

Manufacturing Process

The manufacturing of hot dipped galvanized wire involves several key steps

1. Cleaning The wire is first cleaned using methods such as acid pickling to remove any impurities or oxidation that may affect the quality of the zinc coating.

2. Galvanization The cleaned wire is then drawn through a molten zinc bath. The temperature of the zinc typically ranges between 450-460°C (842-860°F).

3. Cooling and Inspection After galvanization, the wire is cooled, and its coating thickness is checked to ensure it meets industry standards.

4. Spooling Finally, the galvanized wire is spooled for packaging and shipping, ready for various applications.

Advantages of Hot Dipped Galvanized Wire

Hot dipped galvanized wire offers numerous advantages that make it a preferred choice in many applications

hot dipped galvanized wire

1. Corrosion Resistance The primary benefit of hot dipped galvanized wire is its excellent resistance to corrosion. The zinc coating serves as a protective layer, extending the lifespan of the wire significantly compared to other types of wire.

2. Durability Hot dipped galvanized wire is known for its strength and durability. It can withstand harsh environmental conditions, making it ideal for outdoor installations.

3. Cost-Effectiveness Although the initial cost may be higher than non-galvanized wire, the long-term benefits, including reduced maintenance and replacement costs, make it a cost-effective option.

4. Variety of Sizes and Coatings Hot dipped galvanized wire is available in a range of sizes and coating thicknesses, allowing for customization to meet specific project requirements.

Applications of Hot Dipped Galvanized Wire

The versatility of hot dipped galvanized wire makes it suitable for a wide array of applications

1. Construction It is often used in construction for reinforcing concrete, tie wires, and fencing. The corrosion-resistant nature ensures longevity in structural applications.

2. Agriculture Farmers use hot dipped galvanized wire for fencing livestock, creating trellises for plants, and supporting various agricultural structures.

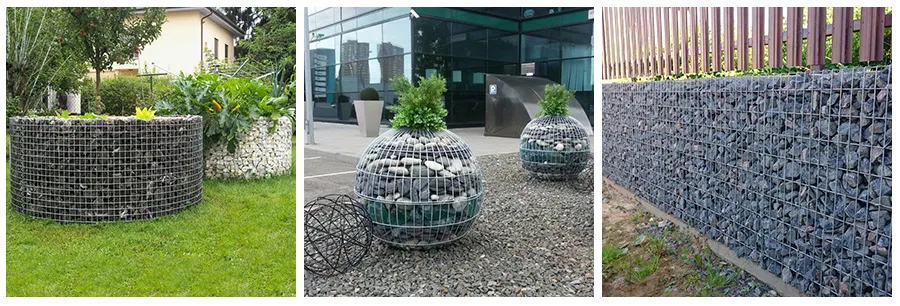

3. Industrial Uses Industries often utilize this wire in the manufacturing of products such as wire mesh, and when constructing storage units and racks.

4. Electrical Applications Hot dipped galvanized wire is also employed in electrical applications as it helps in grounding systems due to its conductivity.

Conclusion

Hot dipped galvanized wire is an essential material in numerous industries, offering unparalleled corrosion resistance, durability, and cost-effectiveness. Its various applications in construction, agriculture, industry, and electrical systems highlight its versatility and importance in modern infrastructure. As industries continue to evolve, the demand for reliable materials like hot dipped galvanized wire is expected to grow, ensuring it remains a staple in future developments.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025