-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 10, 2024 10:56 Back to list

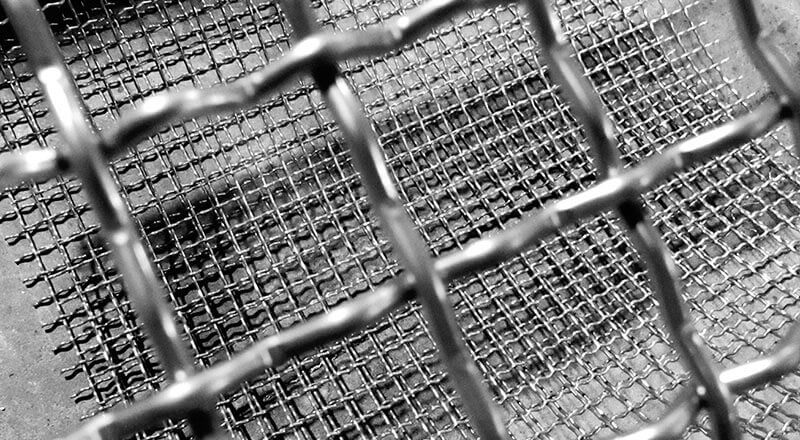

Top Suppliers of High-Quality Iron Mesh Wire for Various Applications

The Evolution and Importance of Iron Mesh Wire Manufacturers

Iron mesh wire, a cornerstone of various industries, plays a crucial role in construction, agriculture, engineering, and more. Its diverse applications range from fencing to reinforcement in concrete structures, making it essential for both large-scale projects and everyday use. The evolution of iron mesh wire manufacturers has been significant, reflecting advancements in technology, material science, and manufacturing processes.

Historical Overview

The production of iron wire dates back centuries, with blacksmiths utilizing manual techniques to create various forms of wire for practical use. Historically, iron mesh was often handmade and labor-intensive, limiting its availability and creating a demand for innovative methods of production. As industrialization took hold in the 19th century, the introduction of machinery revolutionized the manufacturing process, leading to higher production rates and improved quality. This shift not only made iron mesh wire more accessible but also expanded its potential uses in various sectors.

Technological Advancements

Modern iron mesh wire manufacturers harness advanced technologies to enhance production efficiency and product quality. Techniques such as wire drawing, welding, and automated weaving have drastically improved the consistency and durability of the finished product. With the adoption of automated machinery, manufacturers can produce mesh wire in large quantities while maintaining precision and minimizing waste.

Moreover, computer-aided design (CAD) software allows manufacturers to tailor products to meet specific client demands. This customization is vital in industries like construction, where different projects may require specific mesh dimensions, gauge thickness, and material properties.

Material Science Innovations

The development of new materials has also played a pivotal role in the iron mesh wire industry. While traditional mild steel remains popular due to its strength and affordability, manufacturers are increasingly exploring alternatives such as stainless steel and galvanized iron. These materials offer greater resistance to corrosion and prolong the life of the wire, making them suitable for outdoor applications and harsh environments.

iron mesh wire manufacturers

Additionally, manufacturers are now incorporating eco-friendly practices in their production processes. This shift toward sustainable materials and energy-efficient practices reflects growing environmental concerns and consumer awareness. Manufacturers who prioritize sustainability not only contribute to protecting the environment but also enhance their brand reputation and market competitiveness.

Applications Across Industries

Iron mesh wire is indispensable in various sectors. In the construction industry, it is commonly used for reinforcing concrete slabs, ensuring structural integrity and longevity. The agricultural sector utilizes iron mesh for fencing, enabling effective management of livestock and crop protection. Additionally, the production of industrial mesh plays a significant role in creating filtration systems, safety barriers, and decorative features.

In recent years, the demand for iron mesh wire in the architectural and design spheres has increased. Innovative designs incorporating mesh wire add aesthetic appeal while maintaining functionality, leading to a blend of creativity and practicality in building facades, gardens, and urban spaces.

The Global Market Landscape

The global market for iron mesh wire is burgeoning, driven by urbanization, infrastructure development, and increased construction activities. Countries experiencing rapid growth, particularly in Asia, are significant consumers, leading to a surge in local manufacturing facilities. However, competition is fierce, and manufacturers must continually innovate to differentiate themselves in the market.

Collaboration between manufacturers and end-users is becoming increasingly common, fostering a deeper understanding of specific needs and challenges. Such partnerships ensure that manufacturers produce high-quality, tailored products that meet industry standards and regulatory requirements.

Conclusion

As we look toward the future, the role of iron mesh wire manufacturers is set to expand further, with technological advancements and sustainable practices at the forefront. These manufacturers not only contribute to building projects and agricultural endeavors but also play a part in shaping our modern environment. Their ability to adapt to changing demands and incorporate innovative practices will ensure their relevance and importance in the global marketplace for years to come. The story of iron mesh wire is one of transformation and resilience, with manufacturers leading the charge toward a more efficient and sustainable future.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025