-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 10, 2024 08:36 Back to list

iron welded wire mesh factories

The Significance of Iron Welded Wire Mesh Factories

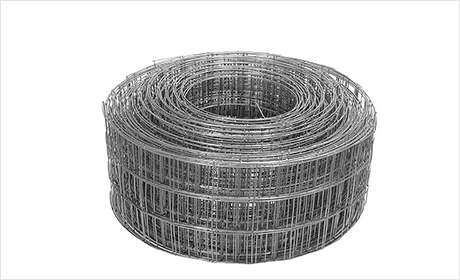

Iron welded wire mesh is an integral component in numerous industrial and construction applications. These products, known for their strength, durability, and versatility, are manufactured by specialized factories dedicated to producing high-quality welded wire mesh. This article explores the operations of iron welded wire mesh factories, the manufacturing processes involved, and their applications in various sectors.

Understanding Iron Welded Wire Mesh

Iron welded wire mesh is formed from cross wires that are welded together at their intersections, resulting in a robust grid structure. Typically made from high carbon steel or low carbon steel, this type of wire mesh is available in various diameters and mesh sizes, allowing for customization to meet specific customer requirements.

The Manufacturing Process

The production of iron welded wire mesh involves several key steps

1. Wire Drawing The manufacturing process begins with wire drawing, wherein large coils of steel are pulled through dies to achieve the desired diameter. This step is critical as it determines the overall strength and flexibility of the finished mesh.

2. Welding Once the wires are drawn to the appropriate size, they are cut to specific lengths. The next step involves placing the wires in a grid format and using automated welding machines to fuse the intersections. This can be performed with resistance welding technology, ensuring a strong bond that enhances the mesh's structural integrity.

3. Surface Treatment After welding, the welded wire mesh may undergo surface treatments such as galvanization, which involves coating the mesh with zinc to prevent corrosion. This treatment significantly extends the lifespan of the wire mesh, making it suitable for outdoor and harsh environments.

4. Cutting and Packaging The final step in the production process is cutting the welded mesh to the required dimensions and packaging it for shipment. Factories often have customized packaging solutions to protect the mesh during transportation and ensure it arrives at its destination in perfect condition.

iron welded wire mesh factories

Applications of Iron Welded Wire Mesh

Iron welded wire mesh has a wide range of applications across various industries, including

- Construction Used in reinforcing concrete structures, wire mesh provides stability and strength to slabs, walls, and foundations. Its use is essential for enhancing the load-bearing capacity of buildings.

- Agriculture Farmers utilize welded wire mesh for fencing, animal enclosures, and garden protection. The strong yet versatile properties of the mesh help safeguard crops and livestock from predators and pests.

- Industrial Use In factories and warehouses, welded wire mesh is often used for safety barriers, storage racks, and partitions. It allows for visibility while maintaining security, making it an ideal solution for various industrial applications.

- Mesh Products Many factories also produce custom mesh products, including screens, trays, and decorative items, catering to specific needs in different sectors.

The Future of Iron Welded Wire Mesh Manufacturing

As industries evolve and demand for high-quality materials increases, iron welded wire mesh factories will continue to adapt by implementing advanced manufacturing technologies and sustainable practices. Emphasizing quality control and efficiency will be paramount in meeting the expectations of modern consumers. Furthermore, with the growing awareness of environmental impact, factories may increasingly adopt eco-friendly practices in production and sourcing of materials.

In conclusion, iron welded wire mesh factories play a crucial role in producing materials that are essential for construction, agriculture, and industry. With their advanced production techniques and commitment to quality, these factories contribute significantly to various sectors, ensuring a reliable supply of essential materials for today's evolving world.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025