-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 27, 2024 08:19 Back to list

Leading Iron Wire Production and Supply Solutions for Various Industries

Iron Wire Manufacturers An Overview of the Industry

Iron wire has been an essential component in various industries around the world, serving multiple applications from construction to crafts. The demand for iron wire has been steadily increasing due to its versatility, strength, and cost-effectiveness. As a result, the role of iron wire manufacturers has become crucial in supplying this foundational material to meet different industrial needs and consumer demands.

The Importance of Iron Wire

Iron wire is primarily used in construction, fencing, industrial applications, and even artistic projects. In construction, it is an integral part of reinforced concrete structures, acting as a tensile reinforcement that enhances the durability and strength of buildings and infrastructure. In addition to construction, iron wire is commonly used in agricultural fencing, providing an essential barrier for livestock and crops.

Moreover, the wire's affordability makes it an ideal choice for many small-scale projects and artisanal crafts, from sculptures to DIY home decorations. As industries evolve and sustainability becomes a priority, iron wire manufacturers are also attempting to embrace eco-friendly practices, recycling scrap metal and ensuring that production processes minimize waste and pollution.

Manufacturing Process

The process of manufacturing iron wire involves several key steps, beginning with the sourcing of raw materials. High-quality iron ore is refined to produce steel, which is then further processed through various methods. One common method is drawing, where steel rods are pulled through progressively smaller dies to achieve the desired wire gauge. Another method is annealing, which involves heating the wire to improve its ductility and tensile strength.

Quality control is paramount in the manufacturing process. Manufacturers often conduct rigorous testing to ensure that their iron wire meets industry standards regarding strength, flexibility, and corrosion resistance. These tests can include tensile strength testing, elongation measurement, and visual inspections for defects. The combination of advanced technology and skilled craftsmanship ultimately leads to high-quality products that satisfy diverse customer requirements.

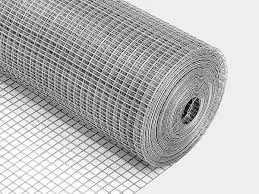

iron wire manufacturer

Industry Players and Market Dynamics

The iron wire manufacturing sector consists of numerous players, ranging from small family-owned businesses to large multinational corporations. The competitiveness of the industry is influenced by factors such as production costs, technological advancements, and market demand. Emerging markets in Asia and Africa are seeing a surge in construction and infrastructural projects, resulting in increased demand for iron wire products.

International trade also plays a significant role. Countries with robust manufacturing capabilities often export their iron wire to nations that require it for construction and other purposes. Trade agreements, tariffs, and global economic conditions can affect supply chains and pricing, making adaptability a necessary trait for manufacturers in this space.

Sustainability in Iron Wire Manufacturing

As global awareness of environmental issues rises, the iron wire manufacturing industry faces pressure to adopt sustainable practices. Many manufacturers are now investing in technology that reduces emissions and energy consumption during production. The recycling of iron and steel is another growing trend, allowing manufacturers to minimize material waste and conserve natural resources. These efforts not only appeal to environmentally conscious consumers but also help companies comply with increasingly stringent environmental regulations.

Conclusion

Iron wire manufacturers play a pivotal role in the construction, agriculture, and craft industries, providing essential materials that facilitate a wide range of applications. As the demand for iron wire continues to rise, the industry must adapt to changing market conditions, incorporate sustainable practices, and embrace innovations in manufacturing technology. With a focus on quality control and operational efficiency, iron wire manufacturers can ensure they meet the diverse needs of their customers while contributing positively to environmental sustainability. As we look ahead, the evolution of this industry will undoubtedly be intertwined with both modern technological advancements and a renewed commitment to protecting our planet.

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025