-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 27, 2024 23:58 Back to list

Leading Manufacturer of Durable Concertina Razor Barbed Wire for Enhanced Security Solutions

The Evolution and Importance of Concertina Razor Barbed Wire Manufacturing

In the realm of security fencing, concertina razor barbed wire has emerged as a critical component for ensuring safety and deterring unauthorized access. This multifaceted barrier is not just a conventional form of fencing; it represents a culmination of innovative design and industrial manufacturing techniques tailored to meet the escalating demands for security in various sectors, from military installations to residential properties.

What is Concertina Razor Barbed Wire?

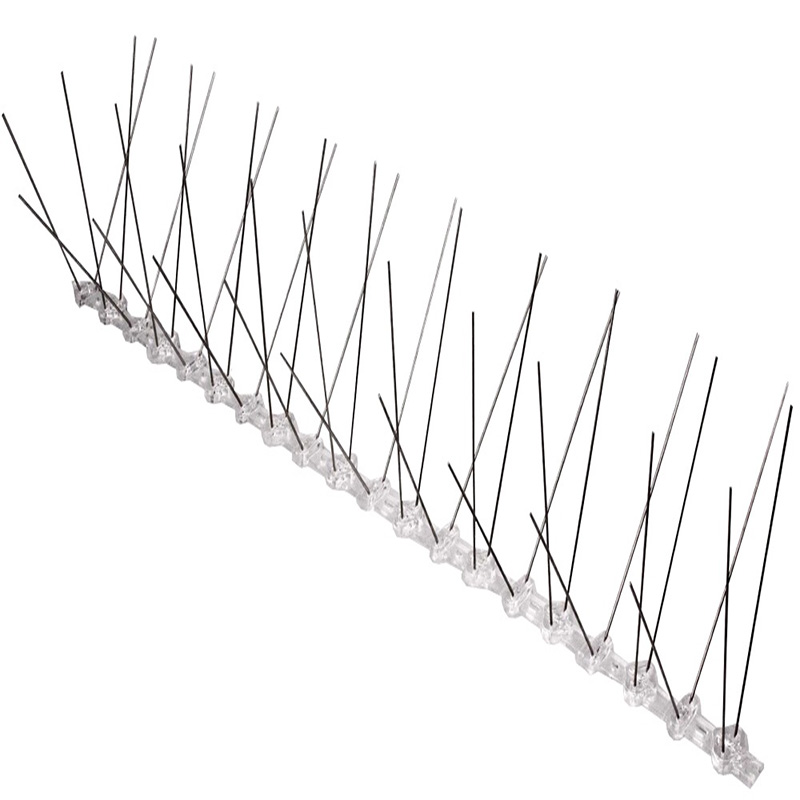

Concertina razor barbed wire, also known as razor wire, consists of a series of sharp-edged blades attached to a wire strand, formed into a spiral structure. This unique design allows for greater deterrence as it poses a substantial challenge to intruders. Unlike traditional barbed wire, which may serve as a mere physical barrier, concertina razor wire's sharp, blade-like edges can inflict serious injury, reinforcing its role as a formidable security measure.

The term concertina refers to the coiled design, which allows the wire to expand and contract. This feature not only makes it easier to install but also enables it to cover large areas effectively without taking up excessive space. The ease of deployment combined with its intimidating appearance makes concertina razor barbed wire a preferred choice for securing high-value sites such as prisons, military bases, and critical infrastructure.

Manufacturing Techniques

The manufacturing of concertina razor barbed wire is a complex process that requires precision and adherence to safety standards. The primary materials used include high-tensile steel wire, which is treated to enhance durability and resistance to corrosion. Modern manufacturing techniques involve the use of advanced machinery that can produce razor wire in various configurations and diameters, allowing for customization according to the specific needs of clients.

concertina razor barbed wire manufacturer

The process begins with the production of flat razor blades, which are typically stamped out of steel sheets. These blades are then attached to wire strands using automation, ensuring each blade is secure and positioned correctly for maximum deterrence. Additionally, the wire is often coated with a protective layer, such as galvanized zinc or PVC, to enhance longevity, especially in harsh environmental conditions.

Quality control is paramount in the manufacturing process. Each batch of concertina razor wire undergoes rigorous testing to meet safety and performance standards. These tests assess the strength of the wire, the sharpness and attachment of the blades, and overall durability. As a result, clients can be assured that the product they receive will be reliable and effective in safeguarding their premises.

Applications and Benefits

Concertina razor barbed wire is widely used across various sectors. In commercial and industrial locations, it provides a reliable mechanism for securing buildings and assets. Its use in military applications is particularly notable, where it serves not only as a physical barrier but also as a psychological deterrent against potential threats.

Moreover, the growing emphasis on security in urban environments has led to increased adoption in residential settings, where property owners seek enhanced protection from theft and vandalism. Training law enforcement personnel in the proper installation and maintenance of such fencing can further boost community safety.

In conclusion, the manufacturing of concertina razor barbed wire reflects a commitment to advancing security measures through innovation and technology. As threats evolve, so too must the methods of protection we employ. Concertina razor barbed wire stands as a testament to our dedication to safety, serving as a bulwark against unauthorized entry while promoting peace of mind for homeowners and businesses alike. The concertina razor barbed wire manufacturer remains at the forefront of this critical industry, ensuring that products continue to evolve and meet the demands of a changing world.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025