-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 22, 2024 05:55 Back to list

Leading Manufacturer of Durable Wire Mesh Cages for Various Applications and Industries

Understanding Wire Mesh Cages A Comprehensive Guide to Their Manufacturing

Wire mesh cages have become essential across various industries, from agriculture to construction and even in the pet care sector. These versatile structures, molded from interwoven metal wire, serve multiple purposes, including containment, support, and protection. As the demand for these products continues to rise, it is essential to consider the role of wire mesh cage manufacturers in ensuring quality, functionality, and durability.

What are Wire Mesh Cages?

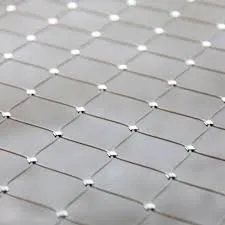

Wire mesh cages are built using a series of wires that are woven together to form a grid-like structure. This grid can be customized in terms of wire thickness, mesh size, and height, depending on the specific application. Common materials used in the production of wire mesh cages include galvanized steel, stainless steel, and plastic-coated wire, each offering unique benefits in terms of strength, corrosion resistance, and aesthetic appeal.

Applications of Wire Mesh Cages

The applications of wire mesh cages are incredibly diverse. In agriculture, they are widely used for livestock containment and for creating enclosures for small animals like rabbits and chickens. Their open structure allows for adequate ventilation and natural light, making them suitable for farming environments.

In the construction industry, wire mesh cages play a crucial role in formwork and scaffolding systems, providing stable support during the building process. They are also frequently utilized in the transportation of hazardous materials, ensuring that goods are securely contained and minimizing the risk of spillage.

Moreover, wire mesh cages have found utility in the pet care industry, allowing owners to provide their animals with safe, secure spaces for play or rest. These cages can be easily customized to fit specific sizes or shape requirements, accommodating various animal species and sizes.

The Manufacturing Process

wire mesh cages manufacturer

The manufacturing of wire mesh cages involves several key steps to ensure that the final product meets the required standards for strength and durability. It typically begins with the selection of the appropriate wire material, which is critical for determining the cage's overall performance and longevity.

Once the material is chosen, the wire is cut to the specified lengths and shaped into the desired mesh pattern. This can be achieved through various methods, including welding or weaving, depending on the intended use of the cage. Quality manufacturers leverage advanced machinery to guarantee precision and consistency throughout the production process.

After the mesh structure is completed, the cages may undergo additional treatments, such as galvanization or powder coating, to enhance corrosion resistance and adapt to the external environment. The final inspection involves rigorous testing to ensure that each cage meets safety and quality standards before being dispatched to customers.

Choosing the Right Manufacturer

When selecting a wire mesh cage manufacturer, it’s essential to consider several factors. First, look for a company with a solid reputation and extensive experience in the industry. High-quality manufacturers focus on using top-grade materials and ensure their products are compliant with safety standards.

Moreover, it’s beneficial to evaluate a manufacturer's customization options. The ability to tailor dimensions, wire size, and coatings to meet specific needs can significantly enhance the functionality of the wire mesh cage.

Lastly, customer service plays a pivotal role. A reliable manufacturer should be responsive to inquiries, ready to provide guidance, and equipped to handle any after-sales support.

Conclusion

Wire mesh cages are invaluable tools that serve a variety of industries. Their versatility, combined with the ongoing advancement in manufacturing techniques, ensures that these cages will continue to meet diverse needs effectively. By choosing a reputable wire mesh cage manufacturer, businesses can ensure they receive quality products that stand the test of time, meeting their specific requirements for safety, reliability, and performance. As the demand for these products grows, so does the importance of investing in quality manufacturing that meets both industry standards and customer expectations.

-

Premium Iron Bar Fence Solutions Reliable Supplier & Exporter

NewsJun.03,2025

-

Best Spiral Tomato Stakes Sturdy Steel Plant Support for Gardens

NewsJun.03,2025

-

Premium Wire Fence Solutions Farm Fencing Suppliers & Exporters

NewsJun.03,2025

-

Arame Farpado Manufacturer High-Strength & Durable Solutions

NewsJun.03,2025

-

Metal Garden Fencing Suppliers Durable & Custom Designs Exported Globally

NewsJun.02,2025

-

Steel Grating Drainage Covers - Trusted Manufacturer & Exporter

NewsJun.02,2025