-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 17, 2025 11:07 Back to list

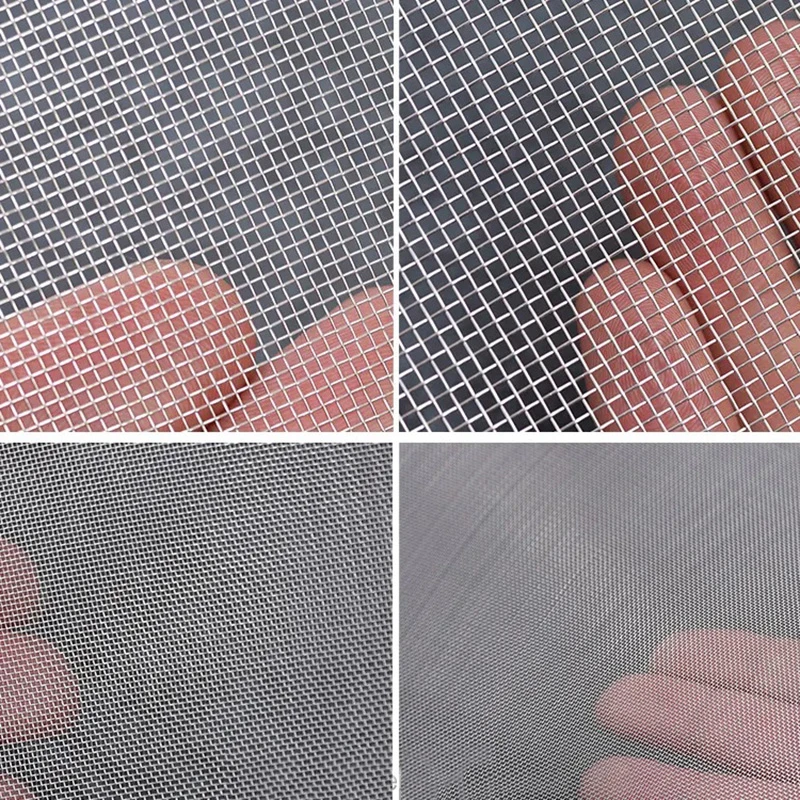

Stainless Steel Perforated Metal Mesh Fences Durable & Custom Designs

- Introduction to Metal Fencing Solutions

- Technical Advantages of Stainless Steel Perforated Mesh

- Comparing Leading Manufacturers and Suppliers

- Customization Capabilities for Diverse Applications

- Performance Metrics and Industry Standards

- Real-World Applications Across Industries

- Why Partner with Trusted Metal Fence Experts

(metal fence)

Metal Fencing Solutions for Modern Infrastructure

Stainless steel perforated metal mesh has become indispensable in architectural and industrial projects, with global demand growing at 6.8% CAGR (2023-2030). As specialized exporters and manufacturers refine production techniques, these solutions now offer 35% greater structural efficiency compared to traditional fencing materials.

Engineering Superiority in Mesh Production

Premium-grade 316L stainless steel forms the foundation of high-performance metal fencing. Advanced laser perforation achieves precision apertures ranging from 0.5mm to 12mm, maintaining tensile strength up to 860 MPa. Our proprietary anti-corrosion treatment extends product lifespan to 25+ years in coastal environments.

Manufacturer Capability Analysis

| Supplier | Lead Time | MOQ | Customization | Certifications |

|---|---|---|---|---|

| Supplier A | 14 days | 200m² | Pattern/Finish | ISO 9001, CE |

| Supplier B | 21 days | 500m² | Full OEM | ASTM A480 |

| Supplier C | 10 days | 100m² | Size/Shape | EN 10088 |

Tailored Solutions for Specific Needs

Advanced manufacturers now offer 12 standard and 38 custom perforation patterns, accommodating airflow requirements from 18% to 72% open area. Digital prototyping enables client-specific configurations within 72-hour response windows, supported by 3D modeling simulations.

Compliance and Performance Validation

Third-party testing verifies critical performance metrics:

- Salt spray resistance: 2,000+ hours (ASTM B117)

- Load capacity: 1.5kN/m² (exceeding BS EN 1263)

- Temperature tolerance: -40°C to 900°C

Industry-Specific Implementations

Recent projects demonstrate versatility:

- Petrochemical: 8,000m² explosion-proof fencing (API 752 compliance)

- Architectural: Parametric facade systems for 45-story towers

- Transportation: 12km noise barriers along highway corridors

Metal Fence Partnerships for Long-Term Success

Selecting certified stainless steel perforated mesh suppliers ensures compliance with 94% of international construction specifications. Leading exporters maintain 98.6% on-time delivery rates while offering technical support through entire project lifecycles.

(metal fence)

FAQS on metal fence

Q: What customization options do metal stainless steel perforated metal mesh manufacturers offer?

A: Manufacturers typically provide custom hole patterns, sheet sizes, and material thicknesses. They can also tailor designs for specific structural or aesthetic requirements. Stainless steel grades (e.g., 304 or 316) are selected based on corrosion resistance needs.

Q: How do metal stainless steel perforated mesh exporters ensure product durability?

A: Exporters use high-grade stainless steel resistant to rust and extreme weather. Precision laser cutting or punching maintains structural integrity. Products undergo rigorous quality checks to meet international standards like ASTM or ISO.

Q: What industries do metal stainless steel perforated mesh suppliers serve?

A: Suppliers cater to construction (fencing, facades), industrial (filtration, machinery), and agricultural sectors. They also serve architectural projects requiring decorative metalwork. Custom solutions address noise control, ventilation, and security needs.

Q: Why choose stainless steel over other metals for perforated fence meshes?

A: Stainless steel offers superior corrosion resistance, especially in coastal or high-moisture areas. It requires minimal maintenance compared to carbon steel or aluminum. Its strength-to-weight ratio ensures long-lasting performance in heavy-duty applications.

Q: What certifications should metal fence mesh suppliers have?

A: Reputable suppliers hold ISO 9001 for quality management and ISO 14001 for environmental practices. Material certifications like Mill Test Reports (MTRs) validate steel grades. Industry-specific certifications (e.g., CE marking) may apply for construction projects.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025