-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 11, 2025 20:30 Back to list

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

Metal Mesh Fabric For Glass Laminated is a key solution in the Material Industry industry, specifically within new material and Functional structural materials. This article explores how HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Metal Mesh Fabric For Glass Laminated Overview

- Benefits & Use Cases of Metal Mesh Fabric For Glass Laminated in Functional structural materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Material Industry

- Conclusion on Metal Mesh Fabric For Glass Laminated from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

Metal Mesh Fabric For Glass Laminated Overview

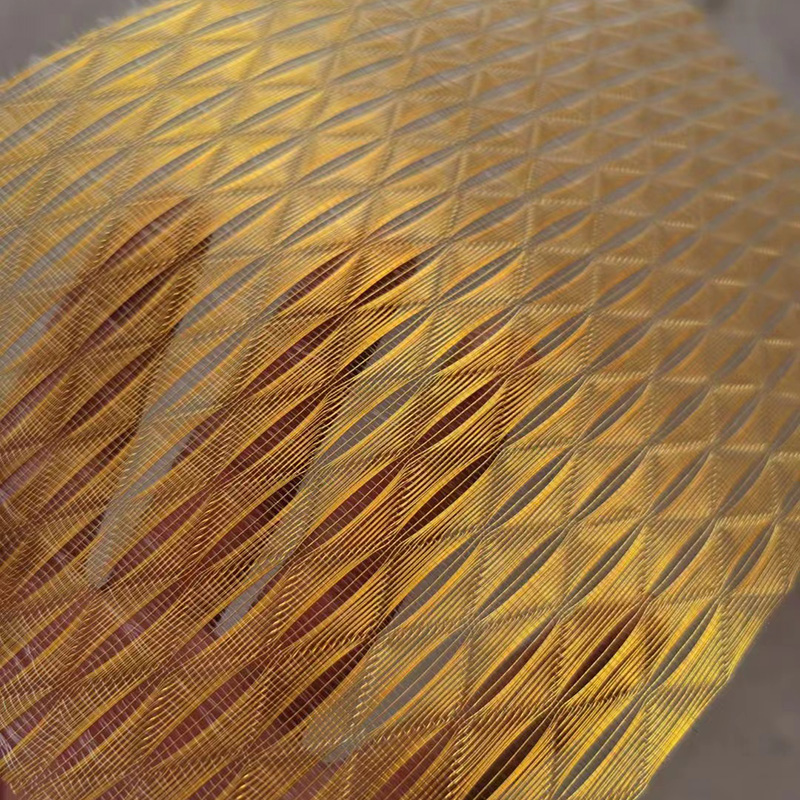

Metal Mesh Fabric For Glass Laminated combines woven metallic fabrics with laminated safety glass using PVB, EVA, or SGP interlayers. The result is a structural, decorative, and high-durability glazing solution that enhances safety and aesthetics while enabling light transmission and privacy control. Typical material options include stainless steel (304/316L), brass, copper, and aluminum. Mesh parameters such as wire diameter (0.1–1.5 mm), aperture/open area (15–65%), and overall laminate thickness (8–25+ mm) can be tuned to meet visual and mechanical targets. For B2B decision makers in architectural, transportation, and interior sectors, this category bridges functional performance with brand-centric design.

- Relevance: offers impact resistance, shatter containment, and controlled transparency for façades, partitions, balustrades, and feature walls across Functional structural materials.

- Technical background: lamination under heat and pressure encapsulates the metal fabric, protecting it from corrosion, moisture, and handling damage; optional surface finishes include passivation, tinning, anodic coloration, or patina for copper alloys.

- Case-in-point: hospitality lobby partitions specified with 316L mesh (≈45% open area) improved daylighting and privacy while meeting safety glazing requirements.

- HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. delivers consistent weave quality, tight tolerances, and project-ready logistics, ensuring reliable supply from prototyping to roll-out.

Benefits & Use Cases of Metal Mesh Fabric For Glass Laminated in Functional structural materials

Across Functional structural materials, laminated mesh glass is specified for building façades, canopies, stair and balcony balustrades, elevator cabs, partitions, skylights, retail fronts, and transit hubs. The embedded mesh enhances post-breakage behavior, supports anti-spall performance, and delivers dynamic visual effects—ranging from subtle shimmer to defined privacy—without adding bulky films or secondary screens. In solar-exposed façades, certain weaves contribute to glare mitigation and reduced solar gain while preserving outward views.

- Competitive advantages: noncombustible metallic core, high durability, easy cleaning like standard laminated glass, stable aesthetics versus printed or film-based solutions, and broad customization (weave style, alloy, openness, and color).

- Performance features: corrosion resistance (especially with 316L), UV-stable interlayers, improved safety glazing characteristics, and design versatility for branding or wayfinding.

- HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supports OEMs, fabricators, and architects with sampling, custom widths, edge preparation, and documentation suitable for certification and project submittals.

Cost, Maintenance & User Experience

Total cost of ownership for Metal Mesh Fabric For Glass Laminated is optimized by long service life, minimal maintenance, and multi-functionality (safety + aesthetics + sun control). Primary cost drivers include alloy selection (e.g., 316L vs. 304), weave density, panel dimensions, edge treatments, and interlayer choice. Compared with applying films, frits, or external screens, laminated mesh can reduce downstream replacements, cleaning complexity, and visual degradation, improving ROI over the building lifecycle.

- Durability & upkeep: clean with standard glass-safe agents; the mesh is sealed inside, protected from abrasion and moisture. No periodic recoating or film replacement is needed.

- User feedback: specifiers appreciate precise openness control for privacy and glare management, while fabricators cite consistent roll-to-roll quality for high yield during cutting and lamination.

- Procurement tip: engage early for weave samples and mockups to align visual intent and daylighting performance with code-compliant glass build-ups.

Sustainability & Market Trends in Material Industry

Sustainability pressures and evolving codes are accelerating adoption of high-performance glazing that balances daylight, energy use, and safety. Metal Mesh Fabric For Glass Laminated supports these goals by enabling solar control and glare reduction without opaque shading, enhancing occupant comfort and potentially reducing HVAC loads. Metals such as stainless steel and aluminum are highly recyclable, and modern interlayers are designed for low emissions and long-term clarity, aligning with green building frameworks like LEED and BREEAM.

- Market trends: growth in mixed-use, hospitality, and transportation projects; increased interest in transparent safety solutions; and demand for customizable, brand-forward façades.

- HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. advances eco-conscious manufacturing through material efficiency, responsible sourcing, and process optimization—delivering consistent quality with reduced waste and dependable lead times for global projects.

Conclusion on Metal Mesh Fabric For Glass Laminated from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

Metal Mesh Fabric For Glass Laminated empowers B2B teams to meet safety, performance, and design objectives in one integrated solution. From façades to interior partitions, its durability, controlled transparency, and low maintenance make it a standout option across Functional structural materials. Backed by HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.’s manufacturing expertise and project support, your specifications stay on time and on budget. Contact us: email: sales@galvanizedmetalmesh.com — Visit our website: https://www.galvanizedmeshproducts.com

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NewsNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NewsNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NewsNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NewsNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NewsNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NewsNov.11,2025