-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 24, 2024 00:37 Back to list

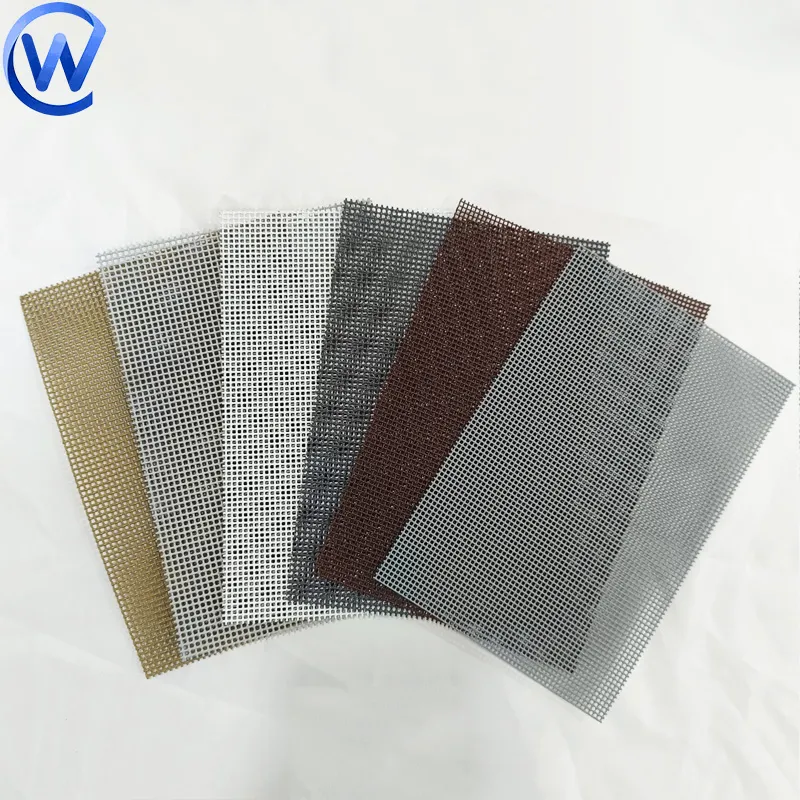

metal stainless steel perforated metal mesh

The Versatility of Stainless Steel Perforated Metal Mesh

Stainless steel perforated metal mesh is a quintessential material in various industries, owing to its strength, durability, and aesthetic appeal. This versatile product is created by punching a series of holes into stainless steel sheets, resulting in a lightweight yet robust mesh that can serve multiple purposes. Whether in architectural applications or functional industrial use, perforated metal mesh offers a unique combination of elements that makes it a preferred choice across various sectors.

One of the key advantages of stainless steel perforated metal mesh is its corrosion resistance. Stainless steel is engineered to withstand environmental factors that typically lead to rust and degradation, making it an ideal choice for applications exposed to moisture, chemicals, or extreme temperatures. For instance, it is often used in food processing plants where sanitary conditions are paramount, as it can be easily cleaned and maintained. Similarly, in marine environments, its resilience to saltwater exposure ensures longevity and reliability.

In architectural design, stainless steel perforated metal mesh has gained popularity for both functional and decorative purposes. Architects and designers utilize this material to create striking facades, ceilings, and partitions that allow light and air to pass through while maintaining privacy and security. Its aesthetic versatility can complement a wide range of designs, from modern minimalism to traditional styles. Additionally, it can be finished in various ways, including polishing, powder coating, or painting, to meet specific design goals.

metal stainless steel perforated metal mesh

Moreover, stainless steel perforated metal mesh is also integral to the manufacturing sector. It serves applications such as filtration, ventilation, and safety barriers. For example, in the automotive industry, it functions as a protective grille that allows airflow while preventing debris from entering sensitive components. In agriculture, it can be used in silos and grain storage to promote airflow and prevent spoilage.

The manufacturing process of stainless steel perforated metal mesh is equally impressive. It involves advanced technologies that ensure precision in hole size, spacing, and overall quality. This allows for tailored solutions that meet specific customer needs, whether it's for industrial equipment, architectural features, or artistic installations.

In conclusion, stainless steel perforated metal mesh is a multifaceted material that meets the demands of modern industry and design. Its combination of durability, aesthetic flexibility, and functionality makes it an indispensable asset in a wide range of applications. As technology advances, the potential uses for this remarkable material continue to expand, solidifying its role as a cornerstone of contemporary materials engineering. Whether in high-rise buildings or manufacturing plants, stainless steel perforated metal mesh stands out as a reliable and innovative solution.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025