-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 27, 2024 06:21 Back to list

High-Quality Stainless Steel Perforated Metal Mesh from Leading Manufacturer

The Rise of Stainless Steel Perforated Metal Mesh in Modern Industries

In today's fast-paced industrial landscape, the demand for durable and versatile materials is more significant than ever. One material that has gained prominence across various sectors is perforated metal mesh, particularly when made from stainless steel. As industries evolve, so do their material requirements, and stainless steel perforated metal mesh has become a go-to choice for manufacturers and design engineers alike.

What is Perforated Metal Mesh?

Perforated metal mesh is a sheet of metal that has been punched with a pattern of holes to create an aesthetically pleasing and functional material. The perforation process allows for the flexibility of designs and offers a variety of hole sizes, shapes, and patterns. When it comes to stainless steel, the advantages of using this material are numerous. Stainless steel is known for its resistance to corrosion, strength, and overall durability, making it an ideal choice for both indoor and outdoor applications.

The Benefits of Stainless Steel Perforated Metal Mesh

1. Corrosion Resistance One of the key advantages of stainless steel is its ability to withstand rust and corrosion. This is particularly crucial in environments that are exposed to moisture, chemicals, or extreme conditions. The longevity of stainless steel perforated metal mesh makes it a cost-effective solution in the long run.

2. Aesthetic Appeal The sleek and industrial look of stainless steel is highly sought after in modern architecture and design. Perforated metal mesh can be used in various applications, from decorative facades to functional partitions, offering both visual appeal and practical use.

3. Lightweight yet Strong Despite being lightweight, stainless steel perforated metal mesh retains significant strength. This unique combination of being easy to handle while offering robust performance makes it attractive for various structural applications.

4. Versatility Its versatility allows it to be utilized in numerous industries, including construction, automotive, aerospace, and food processing. Whether it is for creating safety barriers, filtering systems, or decorative elements, stainless steel perforated metal mesh adapts to various applications seamlessly.

5. Utilization in Filtration Due to its unique hole patterns, stainless steel perforated metal mesh is widely used in filtration applications. Its ability to allow fluid flow while filtering out undesirable particles makes it a crucial component in many industrial processes.

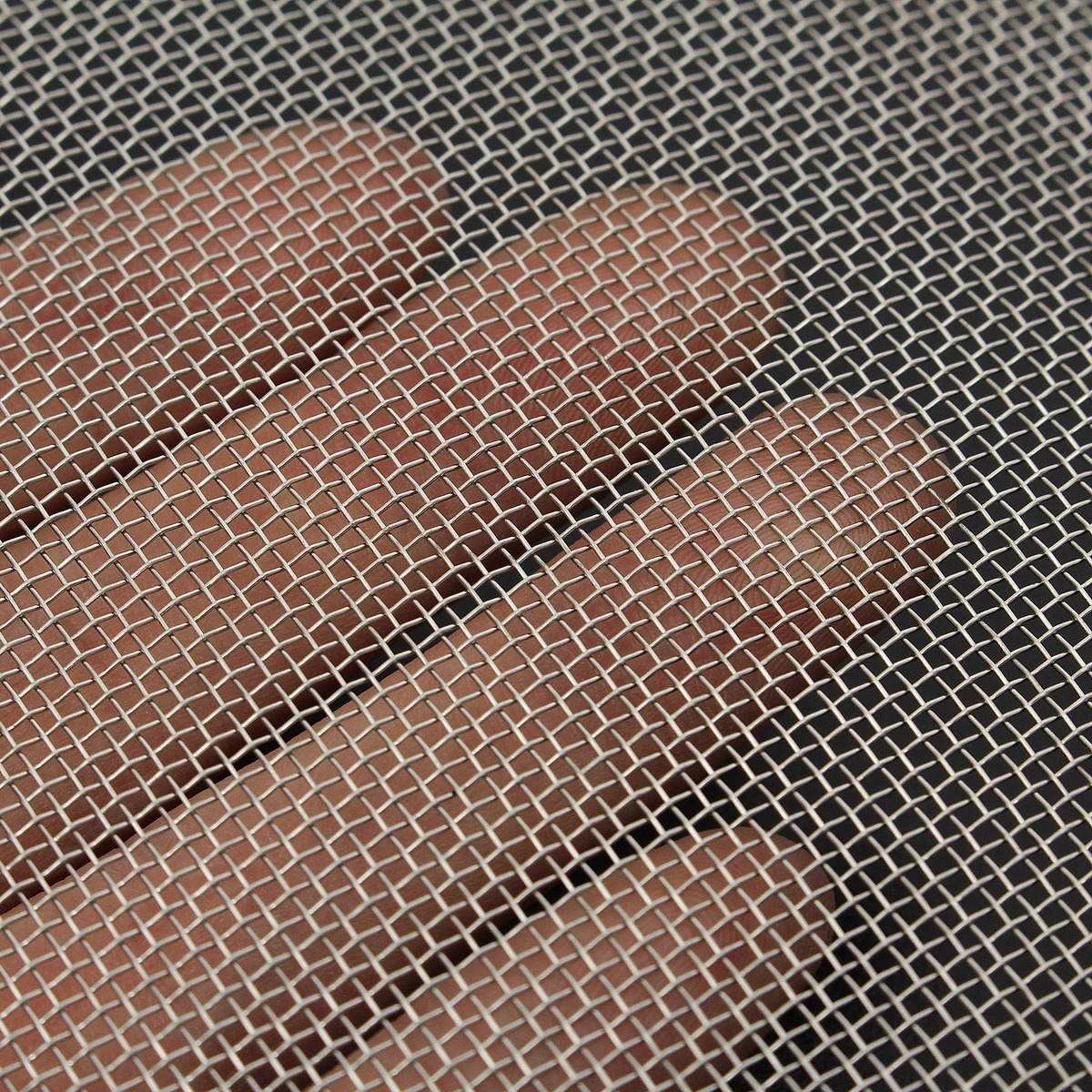

metal stainless steel perforated metal mesh manufacturer

Applications of Stainless Steel Perforated Metal Mesh

The applications of stainless steel perforated metal mesh are virtually limitless. Here are some prominent areas where it is commonly used

- Architecture and Design Urban spaces have seen a rise in the use of perforated metal for facades, sunshades, and decorative panels, enhancing aesthetic design while ensuring functionality.

- Manufacturing In industries such as aerospace and automotive, stainless steel perforated metal mesh is used for lightweight components and structural integrity, where every ounce matters.

- Food Processing Stainless steel’s hygienic properties make it suitable for food processing equipment, ensuring safety and compliance with regulatory standards.

- Construction It is widely used for safety barriers, reinforcing walls, and as part of various architectural features that require both strength and design.

Choosing the Right Manufacturer

When it comes to acquiring stainless steel perforated metal mesh, selecting a reliable manufacturer is crucial. Look for a company that specializes in custom designs, provides high-quality materials, and adheres to industry standards. A good manufacturer will also offer guidance on the various specifications needed for your project, ensuring that you receive the best product tailored to your requirements.

Conclusion

In conclusion, stainless steel perforated metal mesh stands out as a material of choice in modern manufacturing and design. Its combination of durability, aesthetic appeal, versatility, and functionality makes it indispensable across numerous industries. As the demand for innovative materials continues to rise, stainless steel perforated metal mesh is sure to remain at the forefront, providing unmatched solutions for the challenges faced in various applications. Embracing this material not only enhances the quality of products but also contributes to the overall sustainability of industries aiming for longevity and efficiency.

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025

-

Reliable Perforated Stainless Steel Sheets Custom Designs & Export

NewsJun.09,2025