-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 03, 2024 21:06 Back to list

metal wire mesh manufacturers

Metal Wire Mesh Manufacturers A Comprehensive Overview

Metal wire mesh is an essential component in various industries, providing strength, durability, and versatility. Manufacturers of metal wire mesh are crucial in meeting the growing demand for high-quality mesh products, which are used in applications ranging from construction and filtration to automotive and aerospace.

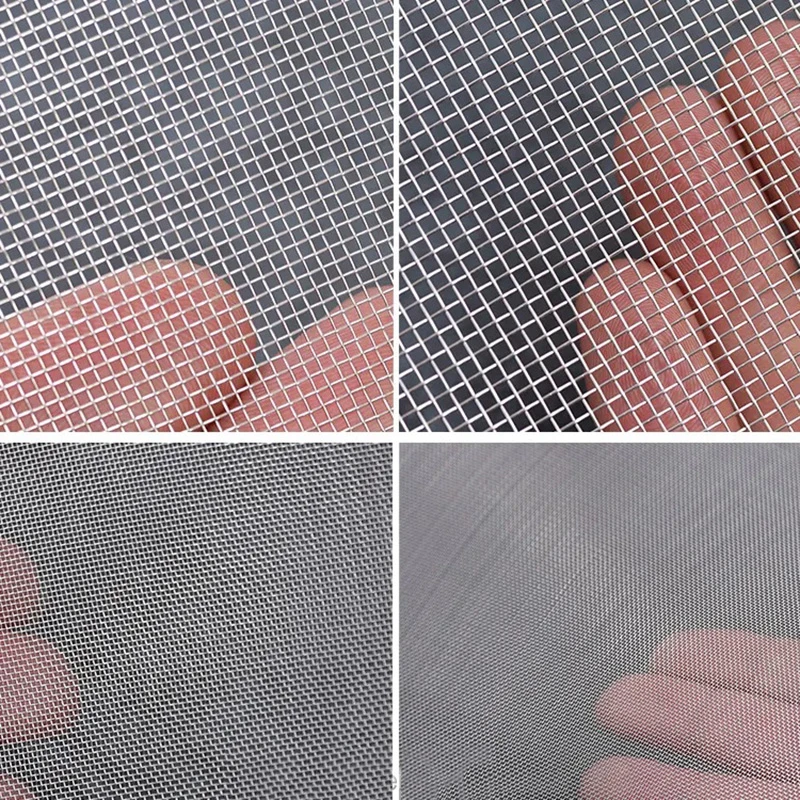

One of the primary reasons for the increasing popularity of metal wire mesh is its wide range of materials. Manufacturers commonly offer meshes made from stainless steel, carbon steel, aluminum, and other alloys. Each material brings unique properties, such as corrosion resistance, strength, and lightweight characteristics, making it suitable for specific applications. For instance, stainless steel wire mesh is favored for its durability and resistance to rust, making it ideal for food processing and medical applications.

The production process of metal wire mesh involves several key steps. First, raw materials are sourced and drawn into wire form. The wire is then woven or welded into mesh, depending on the desired characteristics and the intended application. Different weaving patterns, such as plain weave, twill weave, or Dutch weave, can be employed to achieve various levels of flexibility and strength. Manufacturers often customize mesh specifications, including wire diameter, mesh size, and patterns, to meet their clients' specific needs.

metal wire mesh manufacturers

Quality control is a crucial aspect of the manufacturing process. Reputable metal wire mesh manufacturers adhere to strict quality assurance protocols, ensuring that their products meet industry standards. This includes testing for tensile strength, wire diameter accuracy, and mesh openings. By maintaining high-quality standards, manufacturers can ensure that their products perform reliably under various conditions.

In addition to traditional applications, metal wire mesh has found its way into innovative sectors such as architecture and design. Many architects and designers incorporate wire mesh into building facades, screens, and decorative elements, providing not only structural benefits but also aesthetic appeal. As the demand for unique and sustainable design solutions grows, manufacturers are continuously exploring new materials and techniques to cater to this trend.

The global market for metal wire mesh is expanding, thanks in part to the booming construction and infrastructure industries. With urbanization and population growth driving the need for new buildings, manufacturers are positioned to benefit from increased orders. Additionally, the growth of water treatment and air filtration industries has further spurred demand for high-performance wire mesh products.

In conclusion, metal wire mesh manufacturers play a vital role in delivering high-quality, customized solutions for a diverse array of industries. As technology advances and new applications emerge, these manufacturers will continue to innovate, ensuring that they meet the evolving needs of their customers. Understanding the capabilities and offerings of various manufacturers can help businesses make informed decisions, ultimately contributing to the success and sustainability of their operations.

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025