-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 23, 2024 01:42 Back to list

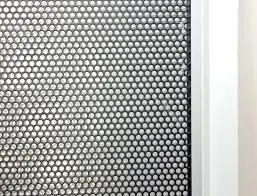

mild steel grate factory

Mild Steel Grate Factory Innovation and Quality in Metal Fabrication

In the realm of industrial manufacturing, the significance of robust and reliable materials cannot be overstated. One such material is mild steel, a versatile metal known for its workability and strength. At the forefront of this industry is the mild steel grate factory, a crucial establishment that plays a vital role in various sectors, including construction, infrastructure, and transportation. This article delves into the operations of a mild steel grate factory, highlighting the importance of quality production, innovative techniques, and the broad applications of mild steel grates.

Understanding Mild Steel

Mild steel, also known as carbon steel, contains a low percentage of carbon—typically less than 0.3%. This composition grants it excellent weldability and ductility, making it an ideal choice for various manufacturing processes. Mild steel's intrinsic properties allow it to be easily shaped and formed into a myriad of products, including grates, which serve as essential components in a range of applications.

The Role of a Mild Steel Grate Factory

A mild steel grate factory specializes in the production of grates made from mild steel. These grates are primarily used in flooring, drainage systems, industrial walkways, platforms, and even in decorative architectural features. The factory employs state-of-the-art machinery and techniques to ensure that each grate produced meets rigorous standards of strength and durability.

The manufacturing process typically begins with raw material selection, where high-quality mild steel is sourced from reputable suppliers. Following this, the steel undergoes a series of processes, including cutting, shaping, and welding, to create precise grate designs. Modern factories often leverage Computer Numerical Control (CNC) technology to enhance accuracy and efficiency, allowing for the mass production of grates tailored to specific requirements.

Quality Assurance and Testing

In a mild steel grate factory, quality assurance is paramount. The grates must withstand significant loads and environmental conditions without succumbing to wear or failure. To ensure this, factories implement strict quality control measures throughout the production process. Each batch of grates is subjected to rigorous testing—this includes checking for structural integrity, load capacity, and resistance to corrosion.

mild steel grate factory

Moreover, many factories adhere to international standards and certifications, ensuring that their products meet the expectations of global markets. This commitment to quality not only enhances the reputation of the factory but also fosters customer trust and satisfaction.

Applications of Mild Steel Grates

Mild steel grates have a multitude of applications across various industries. In construction, they are commonly used for flooring systems, allowing for effective drainage and airflow while providing a safe surface for workers. In municipal applications, mild steel grates are integral to stormwater management systems, helping to prevent flooding by allowing water to flow into drainage systems efficiently.

Additionally, these grates find use in manufacturing and industrial settings. They are often employed in warehouses as flooring solutions on walkways, providing safety without compromising on visibility for below-ground operations. Beyond utilitarian uses, mild steel grates can also be aesthetically pleasing, enhancing the architectural appeal in public spaces and commercial buildings.

Embracing Innovation

With the rapid advancement of technology, a modern mild steel grate factory continually seeks to innovate its processes. This includes adopting sustainable practices such as recycling scrap steel and minimizing waste during production. Furthermore, the integration of automation and smart manufacturing techniques allows for greater efficiency, reduced labor costs, and consistent product quality.

As industries evolve, the demand for customized and high-performance mild steel grates grows. Factories that are willing to adapt and innovate are better positioned to meet these changing needs, ensuring their relevance in a competitive market.

Conclusion

The mild steel grate factory represents a cornerstone of modern metal fabrication, producing essential components that support various industries and infrastructure. With a focus on quality assurance, innovative techniques, and adaptability to customer needs, these factories not only contribute to economic growth but also play a crucial role in building a sustainable future. As the demand for durable and efficient solutions continues to rise, the importance of mild steel grates—and the factories that produce them—will undoubtedly remain significant.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025