-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 29, 2024 21:59 Back to list

perforated steel sheet manufacturers

The Role of Perforated Steel Sheet Manufacturers in Modern Industries

Perforated steel sheets have become an essential component across various industries, thanks to their unique properties and versatility. As industries advance, so does the demand for customized solutions, making perforated steel sheet manufacturers increasingly vital in meeting these requirements.

Understanding Perforated Steel Sheets

Perforated steel sheets are thin, flat pieces of steel that have been mechanically punched to create a pattern of holes or slots. These sheets come in different sizes, thicknesses, and patterns, making them suitable for a variety of applications—from construction and architecture to filtration and automotive industries. The manufacturing process often involves specific techniques such as die-punching, laser cutting, or CNC machining, which ensures precision and durability.

Key Applications

1. Architecture and Design In architectural applications, perforated steel sheets offer not only aesthetic appeal but also functionality. They can be used for facades, railings, and screens, allowing for creative designs that also enhance ventilation and natural light while providing privacy.

2. Filtration In the filtration industry, perforated sheets are crucial for filtering various materials, from water and air to solid substances in industrial processes. Their precise hole patterns can be tailored to meet specific filtration requirements.

3. Industrial and Manufacturing Many manufacturing processes rely on perforated steel sheets for conveyor systems, shelving, and storage solutions. Their strength and customization options make them ideal for heavy-duty applications where weight distribution is crucial.

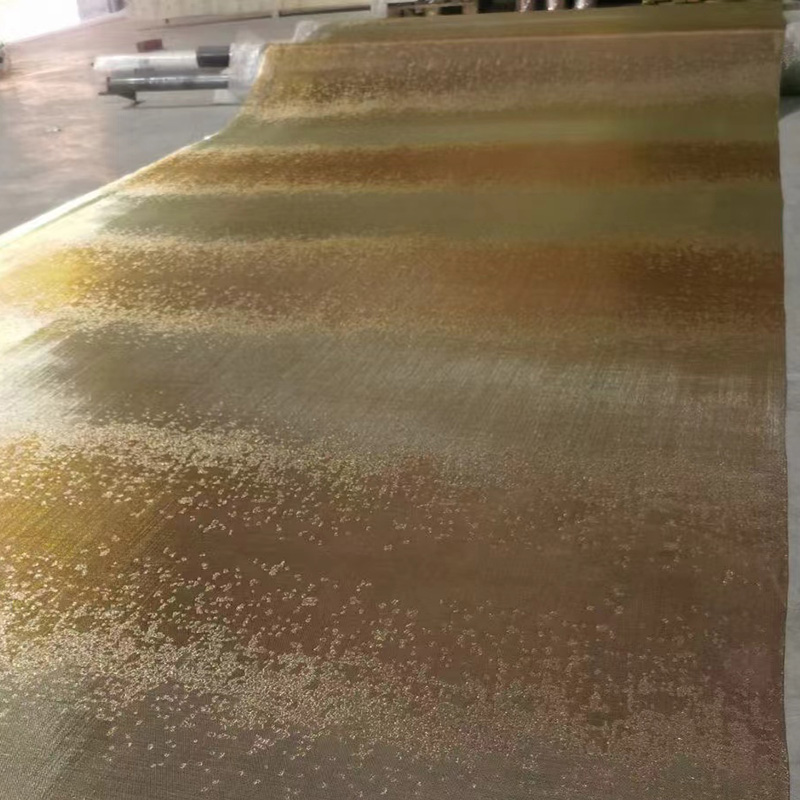

perforated steel sheet manufacturers

4. Transportation In the automotive sector, these sheets are often found in components such as grilles, heat shields, and floor panels. Their lightweight yet robust nature contributes to overall vehicle efficiency and performance.

The Importance of Quality and Customization

With the growing demand for perforated steel sheets, quality assurance becomes paramount. Manufacturers must utilize high-grade raw materials and adhere to strict industry standards. Additionally, customization plays a crucial role in meeting the specific needs of clients. Whether it’s altering the size, shape, or hole pattern, manufacturers work closely with clients to develop tailored solutions that align with their operational requirements.

Sustainability in Manufacturing

As industries globally shift towards more sustainable practices, perforated steel sheet manufacturers are also embracing eco-friendly methods. This includes optimizing production processes to minimize waste and utilizing recycled materials. Many manufacturers are investing in modern technologies that consume less energy, thereby reducing their carbon footprint.

Conclusion

In conclusion, perforated steel sheet manufacturers play a critical role in enabling diverse industries to achieve functional and aesthetic goals. Their ability to provide high-quality, customized solutions positions them as vital players in the supply chain. As technology advances and industries evolve, the importance of these manufacturers will only continue to grow, driving innovation and efficiency across sectors. Whether it’s enhancing design, improving filtration, or supporting sustainable practices, perforated steel sheets are set to remain a key component in the toolbox of modern manufacturing.

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025

-

Reliable Perforated Stainless Steel Sheets Custom Designs & Export

NewsJun.09,2025