-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 30, 2024 01:10 Back to list

Expanded Metal Mesh with Durable Powder Coating for Various Applications

Understanding the Benefits of Powder Coated Expanded Metal Mesh

In recent years, expanded metal mesh has become increasingly popular in various industries due to its strength, versatility, and aesthetic appeal. Among the most innovative approaches to enhance the functionality and appearance of expanded metal mesh is powder coating. This process not only enhances the durability of the mesh but also opens up a wide array of design possibilities for manufacturers and consumers alike.

What is Expanded Metal Mesh?

Expanded metal mesh is a sheet of metal that has been mechanically cut and stretched to create a mesh-like structure. This process results in a lightweight yet robust material that offers an array of benefits, including ventilation, light transmission, and security. Its applications stretch across diverse fields, such as construction, architecture, automotive, and industrial sectors. However, expanded metal in its raw form can be susceptible to corrosion, wear, and aesthetic wear and tear, which can limit its longevity and utility.

The Powder Coating Process

Powder coating is a finishing process that involves applying a dry powder to the surface of the metal. This powder is typically made from a mixture of resin and pigment, which is then cured under heat to form a hard, protective layer. This method is advantageous because it creates a more even and durable finish compared to traditional liquid painting. Furthermore, powder coating doesn't require solvents, making it an environmentally friendly option.

Advantages of Powder Coated Expanded Metal Mesh

1. Enhanced Durability One of the significant benefits of powder coating is its ability to protect the underlying metal from corrosion and rust. This is particularly critical for expanded metal mesh used outdoors or in high-moisture environments.

powder coated expanded metal mesh manufacturer

2. Aesthetic Appeal Powder coating is available in a wide range of colors and finishes, allowing manufacturers to produce expanded metal mesh that meets specific aesthetic requirements. This feature enables architects and designers to use expanded metal in creative ways without compromising on durability.

3. Versatility The characteristics of powder coated expanded metal mesh make it suitable for various applications. From decorative screens in architectural designs to functional barriers in industrial settings, its versatility knows no bounds.

4. Cost-Effectiveness While the initial investment for powder-coated products may be higher than their non-coated counterparts, the long-term savings associated with reduced maintenance and replacement costs make it a wise choice.

5. Environmentally Friendly Since the powder coating process contains fewer volatile organic compounds (VOCs) compared to traditional painting methods, it poses less harm to the environment. Additionally, any overspray from the powder can be reused, minimizing waste.

Applications of Powder Coated Expanded Metal Mesh

The applications of powder coated expanded metal mesh are vast and varied. In the construction industry, it can serve as architectural cladding, walkways, or security fencing. In urban design, it often features in artistic installations, light fixtures, and outdoor furniture. Industrially, powder coated expanded metal can be used for safety barriers, ventilation grills, and shelving units.

Conclusion

The rise of powder coated expanded metal mesh indicates a growing recognition of the need for materials that combine durability, functionality, and aesthetic appeal. As manufacturers continue to innovate and improve their processes, the future looks bright for expanded metal mesh solutions. Whether for industrial applications or cutting-edge architectural designs, powder coated expanded metal mesh offers an excellent choice for those seeking high-quality, versatile, and environmentally friendly materials.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

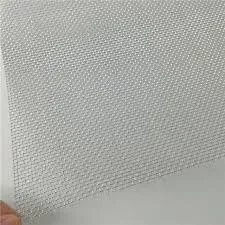

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025