-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 19, 2024 04:26 Back to list

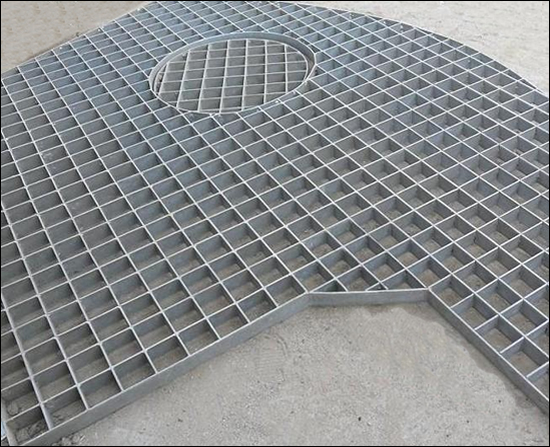

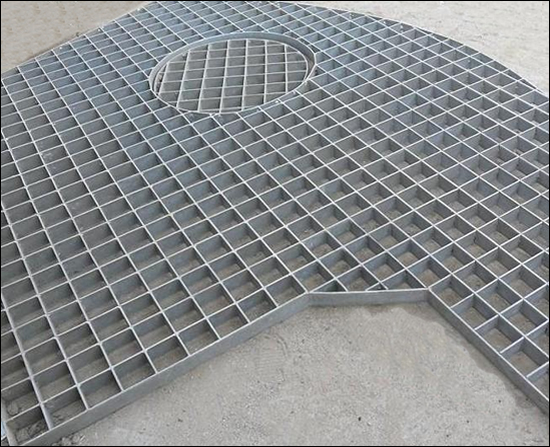

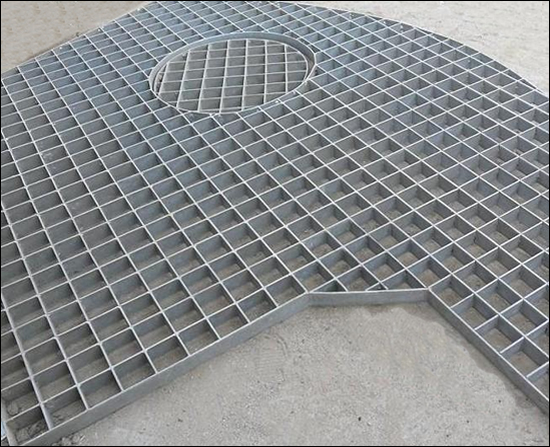

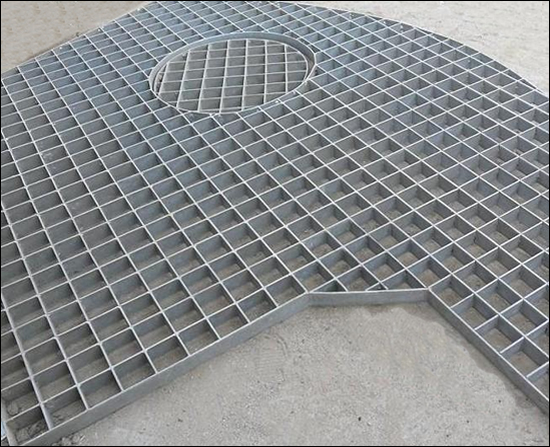

Precision-cut metal mesh plate

The Utility and Versatility of High-Quality Metal Perforated Plates

In the realm of industrial materials, high-quality metal perforated plates stand out for their exceptional durability and multifaceted applications. These plates, crafted from premium metals and meticulously perforated with precise holes, offer a unique blend of strength and functionality that makes them indispensable in various sectors.

Crafted to exacting standards, these metal plates are typically made from robust materials such as stainless steel, aluminum, or brass, ensuring they can withstand harsh environments and resist corrosion. The perforations, often laser-cut for precision, serve multiple purposes they reduce weight, allow for ventilation and filtration, and provide a surface for attachment or integration into larger systems.

One of the most common uses of these plates is in filtration systems where they act as support structures for filter media or as the primary filtering element themselves. In industrial machinery, they can be found as parts of conveyor belts, enabling the transport of small items while allowing debris to fall through. Their heat-resistant properties also make them suitable for use in exhaust systems and heat exchangers.

Moreover, their aesthetic appeal has not gone unnoticed, leading to their increasing use in architectural designs. Perforated metal plates can be seen cladding buildings, offering a balance between an industrial chic appearance and practical functionalities such as solar shading and sound absorption.

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity high quality metal perforated plate. Additionally, in situations requiring safety measures, such as machinery safeguards, perforated metal acts as a protective barrier that allows visual monitoring of processes without compromising on security.

The adaptability of high-quality metal perforated plates is further enhanced by the possibility of customization. Hole sizes, patterns, and plate dimensions can be tailored to specific requirements, making each application uniquely suited to its purpose. This level of customization ensures that these plates are not just standard components but solutions designed to fit the exact needs of diverse industries and projects.

In conclusion, high-quality metal perforated plates are testament to the innovation and adaptability afforded by modern manufacturing techniques. They bridge the gap between form and function, providing both a strong physical presence and an array of practical uses that make them an essential material in countless fields. Whether for industrial, architectural, or safety applications, these plates prove that sometimes, a single well-designed component can make all the difference.

high quality metal perforated plate. Additionally, in situations requiring safety measures, such as machinery safeguards, perforated metal acts as a protective barrier that allows visual monitoring of processes without compromising on security.

The adaptability of high-quality metal perforated plates is further enhanced by the possibility of customization. Hole sizes, patterns, and plate dimensions can be tailored to specific requirements, making each application uniquely suited to its purpose. This level of customization ensures that these plates are not just standard components but solutions designed to fit the exact needs of diverse industries and projects.

In conclusion, high-quality metal perforated plates are testament to the innovation and adaptability afforded by modern manufacturing techniques. They bridge the gap between form and function, providing both a strong physical presence and an array of practical uses that make them an essential material in countless fields. Whether for industrial, architectural, or safety applications, these plates prove that sometimes, a single well-designed component can make all the difference.

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity

In the world of audio equipment, these plates are integral to the design of speakers, providing an optimal surface for sound distribution while maintaining structural integrity high quality metal perforated plate. Additionally, in situations requiring safety measures, such as machinery safeguards, perforated metal acts as a protective barrier that allows visual monitoring of processes without compromising on security.

The adaptability of high-quality metal perforated plates is further enhanced by the possibility of customization. Hole sizes, patterns, and plate dimensions can be tailored to specific requirements, making each application uniquely suited to its purpose. This level of customization ensures that these plates are not just standard components but solutions designed to fit the exact needs of diverse industries and projects.

In conclusion, high-quality metal perforated plates are testament to the innovation and adaptability afforded by modern manufacturing techniques. They bridge the gap between form and function, providing both a strong physical presence and an array of practical uses that make them an essential material in countless fields. Whether for industrial, architectural, or safety applications, these plates prove that sometimes, a single well-designed component can make all the difference.

high quality metal perforated plate. Additionally, in situations requiring safety measures, such as machinery safeguards, perforated metal acts as a protective barrier that allows visual monitoring of processes without compromising on security.

The adaptability of high-quality metal perforated plates is further enhanced by the possibility of customization. Hole sizes, patterns, and plate dimensions can be tailored to specific requirements, making each application uniquely suited to its purpose. This level of customization ensures that these plates are not just standard components but solutions designed to fit the exact needs of diverse industries and projects.

In conclusion, high-quality metal perforated plates are testament to the innovation and adaptability afforded by modern manufacturing techniques. They bridge the gap between form and function, providing both a strong physical presence and an array of practical uses that make them an essential material in countless fields. Whether for industrial, architectural, or safety applications, these plates prove that sometimes, a single well-designed component can make all the difference. Latest news

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025